×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Passat Brake Hose

Brake Line- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Brake Hoses found

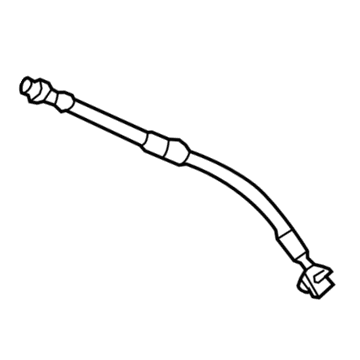

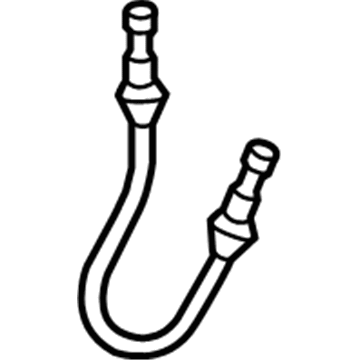

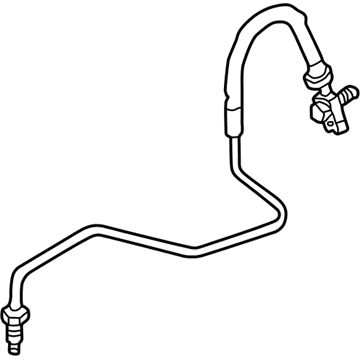

Volkswagen Passat Flex Hose Part Number: 561-611-775-B

$33.47 MSRP: $55.78You Save: $22.31 (40%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 5C0-611-775-C

$39.59 MSRP: $54.98You Save: $15.39 (28%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 5C0-611-776

$39.59 MSRP: $54.98You Save: $15.39 (28%)Ships in 1-2 Business DaysVolkswagen Passat Brake Line Part Number: 4B3-611-722-C

$24.34 MSRP: $39.90You Save: $15.56 (39%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 1K0-611-775-C

$34.91 MSRP: $58.18You Save: $23.27 (40%)Ships in 1-2 Business DaysVolkswagen Passat Brake Hose Part Number: 8E0-611-775-J

$40.70 MSRP: $56.53You Save: $15.83 (28%)Volkswagen Passat Hose Part Number: 893-611-775-A

$41.95 MSRP: $58.27You Save: $16.32 (29%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 3B7-611-775

$55.20 MSRP: $76.67You Save: $21.47 (28%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 5C0-611-701-A

$73.77 MSRP: $103.32You Save: $29.55 (29%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 5N0-611-775-B

$74.96 MSRP: $104.98You Save: $30.02 (29%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 3AA-611-701-A

$76.15 MSRP: $106.65You Save: $30.50 (29%)Ships in 1-2 Business DaysVolkswagen Passat Brake Line Part Number: 3C0-611-763-A

$78.53 MSRP: $109.98You Save: $31.45 (29%)Ships in 1-2 Business DaysVolkswagen Passat Brake Line Part Number: 3C0-611-764-A

$78.53 MSRP: $109.98You Save: $31.45 (29%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 4B0-611-775-C

$83.29 MSRP: $116.65You Save: $33.36 (29%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 3C0-611-701-J

$78.99 MSRP: $110.63You Save: $31.64 (29%)Ships in 1-2 Business DaysVolkswagen Passat Brake Hose Part Number: 8E0-611-763-K

$96.38 MSRP: $134.98You Save: $38.60 (29%)Ships in 1-2 Business DaysVolkswagen Passat Brake Hose Part Number: 8E0-611-764-K

$104.71 MSRP: $146.65You Save: $41.94 (29%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 3U0-611-707

$47.26 MSRP: $65.63You Save: $18.37 (28%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 4E0-611-775-L

$57.23 MSRP: $79.48You Save: $22.25 (28%)Ships in 1-2 Business DaysVolkswagen Passat Flex Hose Part Number: 5C0-611-701-C

$73.77 MSRP: $103.32You Save: $29.55 (29%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 22 Results

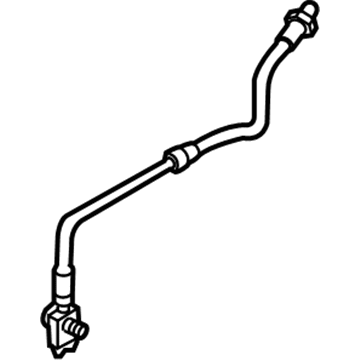

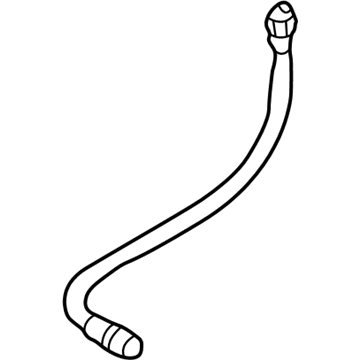

Volkswagen Passat Brake Hose

Choose OEM Brake Hose for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Brake Hose on your Passat, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Passat parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Passat Brake Hose Parts and Q&A

- Q: How often should you inspect the brake hose connecting the steel brake lines with the brake assemblies on Volkswagen Passat?A:The rubber hoses of the steel brake lines should be inspected at a regular rate of about every six months, with the vehicle elevated and placed upon jackstands, to check cracks, chafing, leaks, blisters and other damage in the hoses, since they are vital components of the brake system. A check will be conducted properly with the help of a light and a mirror, and hoses with traces of wear must be changed. To reduce wastage of fluid during replacement of any pipe/ hose, place the polyethylene over the top of the master cylinder reservoir before fitting it or screw a brake hose before clamping a brake hose and then plug or cap metal brake line fittings immediately after disconnection. Put any rag under any appropriate fitting to prevent any spilled fluid and when removing a flexible hose, unscrew brake line fitting and remove spring clip where the hose is attached. The fitting nuts should be unscrewed with a flare nut wrench, to prevent rounded off corners, and the fitting and the surrounding place should be cleaned. Where a component has a number of fittings, record the connections carefully in case it is removed. Replacing metal brake lines, replace with the correct parts not with copper tubing, and use prefabricated brake lines, which are sold by auto parts stores and have to be curved to the right shapes. Make sure that the new line is well bracketed with a clearance of moving or hot parts and should not overtighten fitting nuts. Ensure that the pipes and hoses are properly laid without kinking and fixed in the supplied clips or brackets. Once installed, drain the hydraulic system by removing the polyethylene sheet in the reservoir, wash and dry any spill in the hydraulic system with water and leaks.

Related Volkswagen Passat Parts

Browse by Year

2022 Brake Hose 2021 Brake Hose 2020 Brake Hose 2019 Brake Hose 2018 Brake Hose 2017 Brake Hose 2016 Brake Hose 2015 Brake Hose 2014 Brake Hose 2013 Brake Hose 2012 Brake Hose 2010 Brake Hose 2009 Brake Hose 2008 Brake Hose 2007 Brake Hose 2006 Brake Hose 2005 Brake Hose 2004 Brake Hose 2003 Brake Hose 2002 Brake Hose 2001 Brake Hose 2000 Brake Hose 1999 Brake Hose 1998 Brake Hose 1997 Brake Hose 1996 Brake Hose 1995 Brake Hose 1994 Brake Hose 1993 Brake Hose 1992 Brake Hose 1991 Brake Hose 1990 Brake Hose