×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Transporter Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Shock Absorbers found

Volkswagen Transporter Shock Absorber Part Number: 251-513-031-G

$61.40 MSRP: $86.00You Save: $24.60 (29%)Ships in 1-2 Business DaysVolkswagen Transporter Shock Absorber Part Number: 251-413-031-J

$94.25 MSRP: $132.00You Save: $37.75 (29%)

Volkswagen Transporter Shock Absorber

Choose OEM Shock Absorber for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Shock Absorber on your Transporter, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Transporter parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Transporter Shock Absorber Parts and Q&A

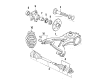

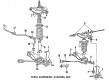

- Q: How are front and rear shock absorbers removed and inspected on Volkswagen Transporter?A:To remove the front dampers, the nut and bolt connecting the upper end of the front axis beam and plate is undone and the nut connecting them to the lower torsion arm stud is removed, and the lower end is installed first during replacement. Rear dampers are also fixed, the upper end being fixed by a bolt into a captive nut in the bracket connecting the side frames, and a lock washer being on each side of the bush, the lower end being fixed by a nut and a bolt, through a lug, on the rear wheel bearing housing. There is a danger of the mounting stud being worn when checking the shock absorber bushes on one of the front damper mounts; rusty threads can break open when trying to unscrew the nut, which means that it will need to be cut off, drilled out and reamed to take a larger replacement pin. The dampers are to be examined by taking them vertically, and fully opening and closing, making sure they offer firm constant resistance in all directions through which the piston travels, and that they offer equal resistance in both directions; any tight or free spots indicate a failure of internal seals, and must be replaced, but minor amounts of oil may not indicate failure.