×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine 2007 Volkswagen Rabbit Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Cylinder Head found

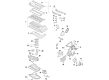

2007 Volkswagen Rabbit Cylinder Head Part Number: 07K-103-063-F

$1501.50 MSRP: $1758.20You Save: $256.70 (15%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 07K-103-285-E

- Item Weight: 36.70 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 07K-103-063-F

- Warranty: This genuine part is guaranteed by Volkswagen's factory warranty.

2007 Volkswagen Rabbit Cylinder Head Parts and Q&A

- Q: What precautions should be taken when disconnecting the battery and removing the cylinder head for Five-cylinder engines on 2007 Volkswagen Rabbit?A: When the battery is disconnected, there are a number of systems that one has to go through re-learning before they can work correctly. The first step in the removal process is to release the fuel system pressure and then take the battery and the battery tray. Lift the front part of the car and place it firmly on jackstands at the other end and block the wheels. Take off splash shield under the vehicle and engine cover. The second thing you should do is to take out the alternator and ignition coils, and, where they are available, the power steering pump. Drain system and eliminate expansion tank of the coolant. Take out the valve cover and the intake manifold, and put the support strap back. Disassemble the camshaft chain cover, lock the camshafts, and then remove the camshaft sprockets and leave the camshaft timing chain lying on the side. Disconnect the exhaust pipe to the exhaust manifold, disconnect the electrical connectors of the oxygen sensor, and shift any harness retainers. Unscrew the cylinder head bolts in reverse of the order of installation, and at the end of the cylinder head bolt nearest the camshaft holding tool, it may not be possible to remove the bolt, so loosen the tool one turn then slide it aside, remove the bolt and retighten the tool. To check, the mating surfaces of the cylinder head and cylinder block must be thoroughly clean when changing the head with spray-on gasket remover and scraper of hard plastic or wood to wipe all of the gasket and carbon away. Care should be exercised when cleaning because aluminum alloy is easily damaged and carbon should not find its way to oil and water passages. To ensure that no carbon penetrates the gap between the pistons and bores, apply a little grease in the gap before cleaning it. Inspect the mating surfaces with a precision straight-edge and feeler gauges, looking for nicks, deep scratches, and other damage, and both surfaces should not be more than the warpage limit; otherwise the component should be replaced. Installation To install, wipe the mating surfaces and apply the alignment dowels. Make sure that cylinder head bolt holes are not filled with oil or water and it can cause hydraulic lock. Place a amount of RTV sealant measuring 1/8-inch bead on the clean surfaces of the timing chain area of the cylinder block as per the recommendations of the manufacturer of the sealant about the curing time. Install a new gasket on the surface of the cylinder block and over the alignment dowels taking care that the top mark is facing up and apply a bead of RTV sealant on the top of the head gasket. The cylinder head is also to be installed with assistance and the chain of the camshaft is to be run through the opening. Apply engine oil to the new thread of the cylinder bolts, attach the new bolts and tighten them in the given order gradually to the required torque value with angle torque method being used in the final steps. Prop the engine and leave it without rotating the crankshaft to 30 minutes. Adjust the valve timing and leave the camshaft holding tool and crankshaft locking pin out, then rotate the crankshaft by hand, rotating it at least one full step, and examining it for any resistance. Reinsertion of the other components that are removed is the opposite of the removal, after which, the engine oil and filter are changed and the cooling system refilled.