×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Rabbit Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Cylinder Heads found

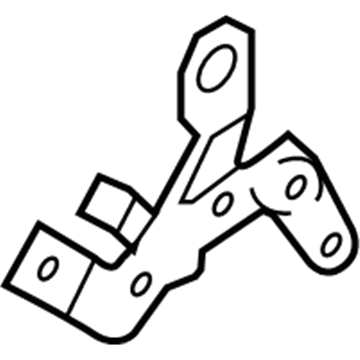

Volkswagen Rabbit Cylinder Head Part Number: 068-103-265-FX

$1078.95 MSRP: $1350.00You Save: $271.05 (21%)Volkswagen Rabbit Cylinder Head Part Number: 026-103-351-E

$832.65 MSRP: $1050.00You Save: $217.35 (21%)Volkswagen Rabbit Cylinder Head Part Number: 07K-103-063-F

$1501.50 MSRP: $1758.20You Save: $256.70 (15%)Ships in 1-2 Business Days

Volkswagen Rabbit Cylinder Head

Choose OEM Cylinder Head for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Cylinder Head on your Rabbit, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Rabbit parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Rabbit Cylinder Head Parts and Q&A

- Q: What precautions should be taken regarding the Cylinder Head when disconnecting the battery and performing engine work for Four-cylinder engines on Volkswagen Rabbit?A:When the battery is taken off, a number of systems need to be re-learned to allow them to work again. When this procedure is performed, a trouble code might be set, and it needs to be cleared using a scan tool. Start by releasing the fuel pressure and uncoupling of the cable with the negative terminal of the battery. Unscrew the right front wheel bolts, lift the front of the car and place it on jackstands. Block one end of the wheels, and take off the right front wheel. The bottom splash shield underneath the engine should be removed, and the engine cover should be removed, working over the vehicle in the engine compartment. Take off the right front inner fender liner and empty out the engine coolant with the engine set to TDC. Further, remove the intake manifold, Timing Belt, rear timing belt cover, exhaust manifold/turbocharger assembly and Valve Cover. On GTI models, pull off the cowl panels, then take the front exhaust pipe/catalytic converter. Disconnect all electrical connectors to the turbocharger, banjo bolts of the oil supply, coolant supply and plug the lines. Disassemble the oil return line that has the fasteners and then detach the return line with the turbocharger then the support bracket that has fasteners and support bracket. Take off the battery and battery tray then the coolant reservoir. Clamp the coolant hoses off at the end of the cylinder head, disconnect and plug the coolant hoses out of the coolant tube and remove the coolant tube retaining fastener of the heat shield. Disassemble the electrical connector on the camshaft adjustment valve and the vacuum hose on the vacuum pump and then remove the electrical harness fasteners and strip off the harness at the end of the cylinder head. Disassemble the electrical connector of the engine coolant temperature sensor, followed by detaching the coolant housing containing fasteners of the end of the cylinder head, being careful to take off the O-ring of the coolant housing. Tighten or loosen the cylinder head bolts by half a turn each time until all are loosened sufficiently to be unscrewed by hand, the bolts must be thrown out and new ones fitted on re-assembly. You have to ensure that you do not have anything attached to the cylinder head; and then remove the head off the cylinder block and get some help, preferably to get the weight. In case of resistance, gently lift the engine head off at a protrusion of the casting. Take off the gasket at the top of the block so that it can be identified. Prior to re-fitting the cylinder head, it should be checked by an engine machine shop. In the case of Timing Chain engine removing the upper timing chain cover, air charge pipe and lower air charge hose is necessary. Detach the front exhaust pipe/catalytic converter, intercooler lower connector pipe and disconnect all the electrical connectors to the turbocharger. Disassemble the oil supply and coolant supply banjo bolts, oil return line, turbocharger support bracket, drivebelt, tensioner and high-pressure fuel pump. Disassemble the hose of the vacuum pump, and insert the hose and cover the port on the vacuum pump. Take off the crankcase ventilation hose, exhaust manifold heat shield, and disconnect the secondary air injection electrical connectors (where applicable). Unplug the electrical connector to the intake manifold and EVAP canister, unplug the coolant hose to the intake manifold and take away the coolant tube. Take off the intake manifold support bracket and unhook the heater hoses to the firewall. Fit a specially designed tool into the control valve, and then turn it clockwise and then extract it. Take off the bearing bracket that contains the fasteners and turn the engine until the No. 1 cylinder reaches the TDC position to confirm the alignment marks. Draw alignment marks between the camshaft timing chain and the sprockets and upper chain guide with a permanent marker. Pull out the tensioner access hole plug, squeegee the timing chain tensioner piston and pull off the tensioner side guide retaining pin. Loosen the locking clip and pull the timing chain upper guide rail. Take off the timing chain of the camshaft sprockets taking care not to turn the engine after the timing chain had been removed. You should take out the ignition coils and unconnect the electrical connector of the camshaft position sensor. Open the cylinder head bolts by unscrewing the ball studs on the cylinder head cover and removal of the oil filler cap. On the cylinder head, first loosen the smaller bolts on the front of the cylinder head with the next bolt removed in a similar manner and so on until the cylinder head is loosened. Create a lifting sling or chain to the cylinder head and put an engine hoist to draw it out very carefully with precaution to avoid damaging the timing chain guide rails. Place the cylinder assembly on a two-block wooden structure and then remove the intake manifold and the exhaust manifold/turbocharger. Remember to keep the mating surface of the cylinder head and cylinder block clean prior to head installation and cleanse it with a scraper to eliminate all signs of gasket and carbon. Examine nicks or scratches on the mating surfaces and examine warpage. Clean the holes of the cylinder head bolts and make certain that the crankshaft is at an alternate position than the TDC prior to reattaching the cylinder head. Install the new head gasket on the cylinder block making sure the markings on its manufacture are facing upwards and position the cylinder head in the middle of the block. Install the new head cylinder bolts and tighten them in increments to the required drive and angle of rotation. In the case of timing belt engines, ensure that the crankshaft is rotated to (TDC) base position of the engine at its base, fix the timing belt tensioner and camshaft sprocker, and position the timing belt. Check resistance by manual rotation of crankshaft. The rest of the installation process is the opposite of removal and then replenishing the engine oil and filter then filling up the cooling system and after that making the engine to run and checking whether there were leaks or not. In the case of timing chain engines, rotate the crankshaft back to TDC and position the timing chain using the marks drawn above, fit the upper guide of the camshaft as well as remove the pin of the tensioner. To ensure that the crankshaft is not resisting, rotate it manually then install the crankshaft in reverse order of removal and then change the engine oil and filter, fill the cooling system and run the engine to ensure that it is not leaking.