×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Distributor

Ignition Distributor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Distributors found

Volkswagen Distributor Part Number: 037-905-205-T

$202.78 MSRP: $284.00You Save: $81.22 (29%)Product Specifications- Other Name: Distributor Assembly

- Replaces: 037-905-205-S

Volkswagen Distributor Assembly Part Number: 051-905-237-X

$129.30 MSRP: $178.88You Save: $49.58 (28%)Product Specifications- Other Name: Distributor

- Replaces: 051-905-205-C

Volkswagen Distributor Part Number: 023-905-237-AX

$229.63 MSRP: $317.20You Save: $87.57 (28%)Product Specifications- Replaces: 023-905-205-C

Volkswagen Distributor Part Number: 023-905-237-X

$262.69 MSRP: $356.00You Save: $93.31 (27%)Product Specifications- Replaces: 023-905-205-B

Volkswagen Distributor Part Number: 037-905-237-BX

$129.30 MSRP: $178.88You Save: $49.58 (28%)Product Specifications- Replaces: 037-905-205-R

Volkswagen Distributor Assembly Part Number: 037-905-237-X

$145.85 MSRP: $201.77You Save: $55.92 (28%)Product Specifications- Other Name: Distributor

- Replaces: 037-905-205-K

Volkswagen Distributor Part Number: 049-905-205-Q

$327.17 MSRP: $446.95You Save: $119.78 (27%)Volkswagen Distributor Part Number: 025-905-237-X

$248.78 MSRP: $337.00You Save: $88.22 (27%)Product Specifications- Other Name: Distributor Assembly

- Replaces: 025-905-205-AG

Volkswagen Distributor Part Number: 021-905-237-X

$323.97 MSRP: $439.00You Save: $115.03 (27%)Product Specifications- Replaces: 021-905-205-AF

Volkswagen Distributor Assembly Part Number: 022-905-205-S

$451.50 MSRP: $616.80You Save: $165.30 (27%)Product Specifications- Other Name: Distributor

Volkswagen Distributor Part Number: 025-905-205-K

$494.10 MSRP: $675.00You Save: $180.90 (27%)Volkswagen Distributor Part Number: 027-905-205-Q

$519.72 MSRP: $710.00You Save: $190.28 (27%)Volkswagen Distributor Part Number: 034-905-205-F

$519.72 MSRP: $710.00You Save: $190.28 (27%)Product Specifications- Other Name: Distributor Assembly

Volkswagen Distributor Assembly Part Number: 026-905-237-X

$401.38 MSRP: $542.60You Save: $141.22 (27%)Product Specifications- Other Name: Distributor

- Replaces: 026-905-205-AH

Volkswagen Distributor Part Number: 048-905-237-X

Volkswagen Distributor

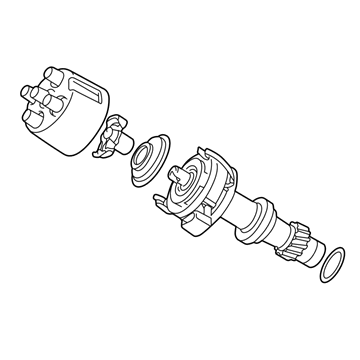

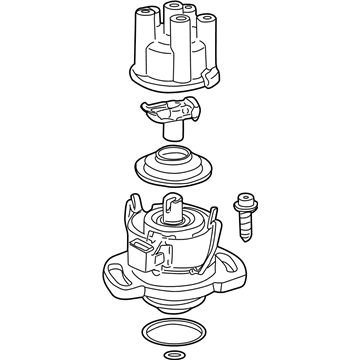

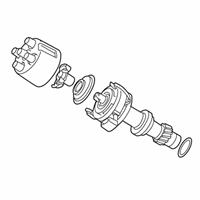

The Volkswagen distributor is very important in your car's ignition system for it to be able to channel the electric current from the ignition coil to the spark plugs. With time, due to extensive use, the distributor may deteriorate and bring about misfires and, finally, total breakdown. Normally, this is because of electrical arcing that wears out only the cap and rotor. However, spark plug wires could also degrade with time and lose electrical insulation. This means that one must regularly repair or replace his distributor.

OEM (Original Equipment Manufacturer) Volkswagen Distributors are perfect for motorists because they are the best quality parts produced as per the manufacturer's specifications; hence, they perform well and are reliable too, thus helping to retain the car's initial functionality as well as safety features. At VWPartsGiant.com, our genuine Volkswagen Distributor supply indicates how much we care about the health of your vehicle. Additionally, our stock is vast, so every product will be easily accessible to you for finding and swapping without fear of making mistakes. With our user-friendly online catalog, it takes no time to identify the right spare part. Therefore, convenience accompanies servicing or maintaining a motorcar. You can rely on our OEM Volkswagen Distributor to sustain the performance of your automobile.

Volkswagen Distributor Parts and Q&A

- Q: How to remove and install a distributor on Volkswagen Cabrio?A:In order to eliminate the distributor, detach the battery negative cable first making sure that it is not touching the terminal and carry an appropriate activation code to any anti-theft system. TDC the engine on cylinder No 1 and, as required, disconnect the four spark plug wires and so the coil wire of the distributor cap, and label them to be later fitted. Unscrew the distributor electrical connector and remove the screws that are in the distributor shield (where applicable) and unplug the electrical connector of the Hall sensor in the distributor body. To install the distributor cap, unscrew or pry off the retaining clips until the distributor cap is lifted off making sure that the rotor electrode fits into the cylinder No 1 marking on the distributor body. Label the relationship between the distributor body and the drive gear case flange with arrows and then loosen and release the bolt to lift off the clamp plate and remove the distributor body off the cylinder block and reclaim the O-ring seal. Look at the O-ring seal(s) and verify wear or damage and replace where necessary and look at the teeth of the distributor drive gear and verify wear or damage, replace the distributor is worn or chipped. To install, ensure that the engine is still in TDC in cylinder No 1. In the case of a 1.8L engine, the tube of the oil pump shaft drive should be aligned with the threaded hole adjacent to the distributor aperture and in the case of a 2.0L engine, aligned with the crankshaft axis. Install the distributor, loosely fasten the clamp plate and the bolt and turn the shaft about a little to fit into the intermediate shaft drive gear, matching the marks created during removal. The rotor electrode is required to be facing directly at the No 1 cylinder mark on the distributor body; the distributor clamp bolt needs to be tightened to a given torque and the alignment of the intermediate shaft sprocket may need to be checked. Install the distributor cap with clips or screws and reconnect the Hall sensor cabling, and install the distributor shield (where applicable) fastened. Install the coil wire by connecting the spark plug wires so as to follow the firing order of 1-3-4-2 and then place the coil wire between the coil and center terminal on the distributor cap. In the case of a 1.8L engine, check the ignition timing, and adjust to the required level.

- Q: What should be done if the distributor components are worn and require maintenance on Volkswagen Transporter?A:Provided the component parts are kept in good order, there should be little need to take the distributor apart except in cases of neglect or very high mileages, indicated by difficulty in setting the measured gap of the contact points accurately and consistently, often due to wear of the shaft or bushes. When wear occurs, movement can be felt when sideways rocking pressure is applied to the top of the shaft. The only solution is to remove the distributor and renew the shaft, or alternatively, renew the whole assembly, ensuring that the necessary parts are available. After removing the distributor, take out the contact points, then remove the driving collar from the bottom of the shaft, noting the orientation of the driving dogs in relation to the rotor arm notch. Clamp the collar in a vice, punch out the retaining pin, and draw off the collar along with the shims controlling the endfloat of the shaft. Carefully unhook the pull rod from the vacuum unit to the contact breaker mounting plate, remove the screws, and take off the vacuum unit, followed by the mounting plate and shaft, noting the position of the thrust washers. If the shaft is badly worn, it must be renewed, but check that the bushes in the distributor are not also worn; if they are, the whole distributor should be replaced. If the shaft and bushes are worn, it is likely that the springs and anchor posts of the centrifugal advance mechanism are also tired, so replacing all components is advisable. Avoid washing the bushes in paraffin or other solvents and ensure they are well lubricated before reassembly. New distributor shafts may require a variation in the thickness of the shims fitted between the driving dog and the body. Reassembly involves reversing the dismantling procedure, ensuring the driving dog is fitted correctly, and peening the ends of the pin to prevent it from dropping out.