×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Golf Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

25 Cylinder Heads found

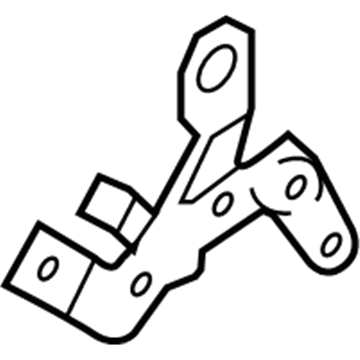

Volkswagen Golf Cylinder Head Part Number: 068-103-265-FX

$1078.95 MSRP: $1350.00You Save: $271.05 (21%)Volkswagen Golf Cylinder Head Part Number: 026-103-351-B

$812.83 MSRP: $1025.00You Save: $212.17 (21%)Volkswagen Golf Cylinder Head Part Number: 026-103-351-N

$832.65 MSRP: $1050.00You Save: $217.35 (21%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 026-103-265-KX

$868.34 MSRP: $1095.00You Save: $226.66 (21%)Volkswagen Golf Cylinder Head Part Number: 037-103-265-X

$868.34 MSRP: $1095.00You Save: $226.66 (21%)Volkswagen Golf Cylinder Head Part Number: 037-103-351-M

$868.34 MSRP: $1095.00You Save: $226.66 (21%)Volkswagen Golf Cylinder Head Part Number: 037-103-351-P

$970.63 MSRP: $1224.00You Save: $253.37 (21%)Volkswagen Golf Cylinder Head Part Number: 037-103-351-N

$998.39 MSRP: $1259.00You Save: $260.61 (21%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 04E-103-061-F

$981.95 MSRP: $1238.28You Save: $256.33 (21%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 07K-103-063-F

$1501.50 MSRP: $1758.20You Save: $256.70 (15%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 028-103-265-HX

$950.48 MSRP: $1188.00You Save: $237.52 (20%)Volkswagen Golf Cylinder Head Part Number: 06A-103-351-A

$1268.79 MSRP: $1485.70You Save: $216.91 (15%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 04L-103-064-E

$1329.62 MSRP: $1556.93You Save: $227.31 (15%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 03L-103-351-J

$1915.39 MSRP: $2242.84You Save: $327.45 (15%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 06L-103-064

$1936.74 MSRP: $2267.84You Save: $331.10 (15%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 038-103-351-B

$2003.84 MSRP: $2346.41You Save: $342.57 (15%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 038-103-265-AX

$1390.79 MSRP: $1628.56You Save: $237.77 (15%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 06A-103-275-AX

$2644.82 MSRP: $3092.06You Save: $447.24 (15%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 07K-103-063-H

$3318.39 MSRP: $3885.70You Save: $567.31 (15%)Ships in 1-2 Business DaysVolkswagen Golf Cylinder Head Part Number: 021-103-265-BX

$3526.47 MSRP: $4128.88You Save: $602.41 (15%)

| Page 1 of 2 |Next >

1-20 of 25 Results

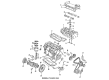

Volkswagen Golf Cylinder Head

The essence of the Volkswagen Golf Cylinder Head is to close the combustion chamber, provide a pathway for air-fuel in, exhaust vent out, and compression to ensure that the engine functions effectively to generate power. Seated on the cylinders, this special block supports spark plugs, valves, coolant passages and intake and exhaust openings, allowing the engine to breathe and release heat. The Cylinder Head should have the least restriction possible, so the castings applied in performance Volkswagen models have heavier walls which can be shaped to allow free flow of air without cutting the water jackets. Over the model years two major types have emerged, the heavy cast iron of early cars and the light aluminum of later, the latter losing mass, radiating heat more quickly, and permitting slightly higher compression to enhance throttle response. No matter the type, Volkswagen uses single-use Torque-to-Yield bolts which stretch to distribute the clamping force evenly, a design which protects the gasket against leaks. When the seal is broken, coolant, oil, and combustion gases can mix, leading to overheating, misfire, or milky fluids, and worn guides, seats, springs, or valves can also rob power or disable a cylinder. The Cylinder Head in the current Golf models is nearly always aluminum and has the effect that the current Volkswagen engines have a friendlier power-to-weight ratio and better weight distribution than the older iron design.

Choose OEM Cylinder Head for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Cylinder Head on your Golf, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Golf parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Golf Cylinder Head Parts and Q&A

- Q: What precautions should be taken regarding the Cylinder Head when disconnecting the battery and performing engine work for 5-cylinder engines on Volkswagen Golf?A:When the battery is removed, a number of systems will have to be re-learned until they will work correctly. The first step is to relieve the fuel system pressure and then release the battery and the battery tray. Lift the front of the vehicle and lift the vehicle safely on jackstands, blocking the wheels at the other end. Take out splash shield on the underside, engine cover, and air filter housing. The next step is to remove the alternator, ignition coils and power steering pump, drain the cooling system and take out the coolant expansion tank. Next, dismantle the Valve Cover and Intake Manifold, then the accessories support bracket bolts and bracket, and put the support strap back in place to help in the process of the cylinder head removal. Take the Camshaft cover off, breadthwise lock the camshafts and disconnect the camshaft sprocket so that the Timing Chain can be out of the way. Unplug the exhaust pipe, the electrical connections of the oxygen sensor, and harness holders. Unscrew the cylinder head bolts in the same order in which they were installed with the exception that the bolt nearest to the tool holding the instrument, cannot be removed, then loosen the tool and slide to the side of the tool to reach the bolt. Inspection: To be inspected, the mating faces of the cylinder head and block should be clean, using a gasket remover and scraper, being careful not to damage the alloy of aluminum. Eliminate carbon deposition around the oil and water outlets, and inspect the surfaces involved in the mating process as a precision straightedge and feeler gauge. In case any surface goes above the limit of warpage, refer to an automotive machine shop. To install, clean the mating surfaces and install the alignment dowels. It is important to make sure that the holes of the cylinder head bolts are not filled with oil or coolant to prevent hydraulic lock. Add a bead of RTV sealant to the area of timing chain of the cylinder block and place a new gasket to the block surface with the mark TOP facing upward. Apply one more bead RTV sealant to the top of the head gasket, and place the cylinder head inside into position within five minutes using an assistant to help. Apply engine oil to the new cylinder bolt threads and install the bolts with your fingers and hand-tighten them in the given order to the first torque value and then repeat the process by one more step using the angle torque technique. Let the engine rest after 30 minutes without turning the crankshaft. Install the accessories bracket and bolts as they come in that order tightening them to the given torque. Tilt the valve timing and pull off the camshaft holding tool and crankshaft locking pin. Turn the crankshaft over at least two full rotations before engaging the engine, and observe resistance. In case any is experienced, then pause and enquire about the matter. Last but not least, fit the rest of the items taken off and replace engine oil and filter, and fill up the cooling system.

Related Volkswagen Golf Parts

Browse by Year

2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head 1987 Cylinder Head 1986 Cylinder Head 1985 Cylinder Head