×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Golf R Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Piston found

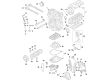

Volkswagen Golf R Piston Part Number: 06K-107-065-AG

$338.54 MSRP: $462.49You Save: $123.95 (27%)Ships in 1-2 Business Days

Volkswagen Golf R Piston

Choose OEM Piston for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Piston on your Golf R, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Golf R parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Golf R Piston Parts and Q&A

- Q: What steps should be taken prior to removing the piston and connecting rod assemblies on Volkswagen Golf R?A:Before the removal of the piston and connecting rod, make sure that you remove the cylinder head, Oil Pans, oil pump, and windage tray provided. Test the ridges on the top of the ring movement with a fingernail, and in case there are any, clean with a ridge reamer as directed by the manufacturers not to break the piston. Once the ridges have been removed, position the engine in such a way that the crankshaft is facing upward. Test the connecting rod endplay by feeler gauges and it should be within the service range of 0.005 to 0.015 inch; otherwise replacement of connecting rods might be required. Locate connecting rods and caps by making sure that marks are focused to drivebelt end and are marked. Bend connecting rod cap bolt progressively enough to be able to loosen it with a hand until it is clear enough to remove the old one to check the oil clearance. Install Take off first connecting rod cap and bearing insert, but do not drop the bearing insert, and force the connecting rod/piston assembly out with a wooden or plastic hammer handle. Check on other cylinders, reassemble caps and inserts and avoid damaging them. In case of piston ring installation, check ring end gaps, make sure that they are within specified limits and make the necessary adjustment. Install the oil control ring with the middle and top rings on top of it keeping in mind the proper direction. Wipe down cylinder walls and chamfer edges before assemblies have been installed and make sure that the crankshaft is in place. Install new bearing inserts, not lubricated, and make sure that they fit. Intervals between position piston rings are 90 degrees between, lubricate the piston and rings, and install with a ring compressor. Test oil clearance between check connecting rod and Plastigage and replace bearings where necessary. Once installed, remove any residues of Plastigage, apply grease to bearing faces and install new bolts, tightening in stages. Repeat on the rest of the assemblies keeping them clean and in a proper orientation. Last, turn the crankshaft to ensure it does not bind and check endplay of the connecting rods; remedies to any problem to be made.