×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Jetta TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 TPMS Sensor found

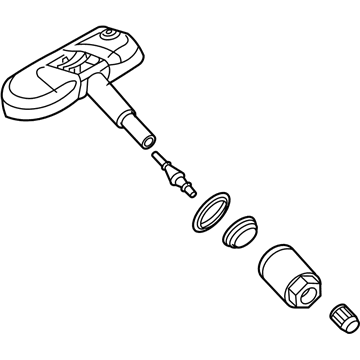

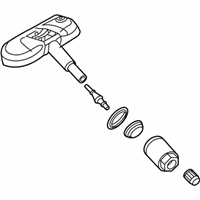

Volkswagen Jetta TPMS Sensor Part Number: 1K0-907-253-D

$136.84 MSRP: $191.65You Save: $54.81 (29%)Ships in 1-2 Business Days

Volkswagen Jetta TPMS Sensor

Choose OEM TPMS Sensor for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace TPMS Sensor on your Jetta, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Jetta parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Jetta TPMS Sensor Parts and Q&A

- Q: How does the TPMS Sensor contribute to preventing being stranded with a flat tire and provide vital information about potential issues in the steering and suspension systems on Volkswagen Jetta?A:Routine checking of the tires would help to avoid the pain and inconvenience of getting stuck with the flat tire and reveal crucial details about any troubles in the steering and suspension mechanisms before significant damage may happen. The tires that are installed on the car have width bands of 1/2-inch which can be seen when the treads of the tires become 1/16-inch in depth, that is, they are worn out. A simple, cheap tread depth indicator which can be purchased in auto parts stores can be used to monitor tread wear. Abnormality in tread wear e.g. cupping or uneven wear can indicate alignment or balance issues in the front end, and a visit to a tire shop is required to rectify. Also, carefully look at the cuts, puncture, and embedded objects such as nails because they may create slow leaks. In case of being aware of slow leak, make sure that the stem core of a valve is tight and the tread does not contain any foreign object. The bubbles will also make the solution of soapy water identify any leaks because the solution will have some bubbles in case of a puncture. Check the inside of the tires of each tire in case there is a leakage of brake fluid, this is something that has to be attended to. It is important to keep the air pressure at the right level to prolong the life of tires, increase the mileage of the vehicle, and improve the quality of the ride; thus, a proper tire pressure gauge is necessary since it can be unreliable at gas stations. A cold tire pressure should be checked and preferably after the vehicle has not travelled more than one mile in the preceding three hours as hot tires may indicate an increase in pressure of four to eight pounds. To measure the pressure, loosen the valve cap and strongly press the gauge on the valve stem and record the reading and compare with the required tire pressure. Install back the valve cap to keep dirt and moisture out and also make sure all four tires are inflated including the spare tire which should also be inflated to the required pressure.