×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

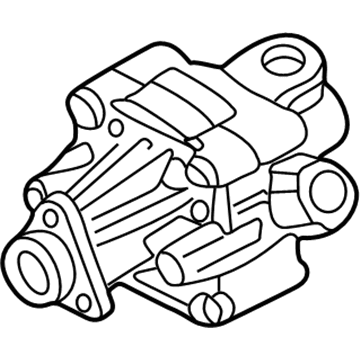

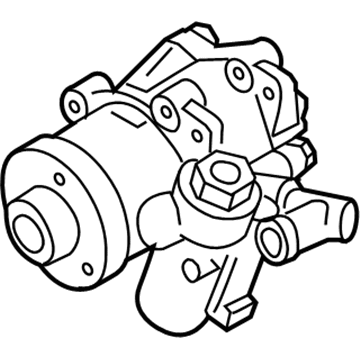

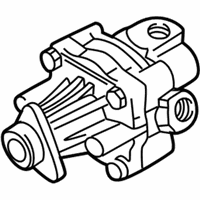

Genuine Volkswagen Passat Power Steering Pump

Power Steering Pump Unit- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

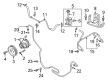

11 Power Steering Pumps found

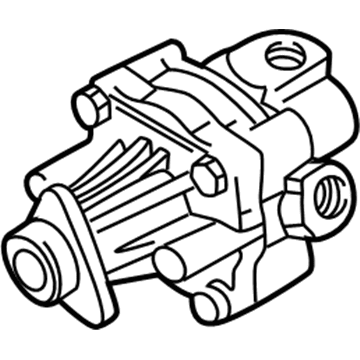

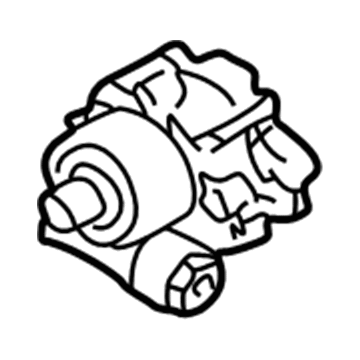

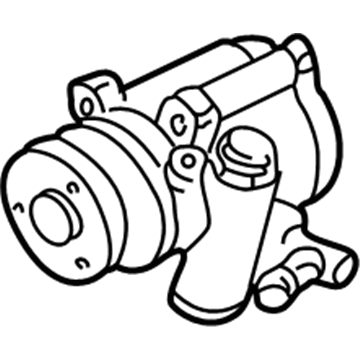

Volkswagen Passat Power Steering Pump Part Number: 8D0-145-156-K

$276.94 MSRP: $378.33You Save: $101.39 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 8D0-145-156-T

$285.48 MSRP: $390.00You Save: $104.52 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 3B0-422-154-H

$345.26 MSRP: $471.67You Save: $126.41 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 027-145-157

$351.36 MSRP: $480.00You Save: $128.64 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 6K0-422-154

$353.56 MSRP: $483.00You Save: $129.44 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 8D0-145-156-FX

$296.50 MSRP: $403.33You Save: $106.83 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 3B7-422-154-A

$395.28 MSRP: $540.00You Save: $144.72 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 8D0-145-156-KX

$337.98 MSRP: $460.00You Save: $122.02 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 8D0-145-156-TX

$337.98 MSRP: $460.00You Save: $122.02 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 6N0-145-157-X

$379.14 MSRP: $516.23You Save: $137.09 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Steering Pump Part Number: 5C0-422-152-J

$509.18 MSRP: $695.61You Save: $186.43 (27%)Ships in 1-2 Business Days

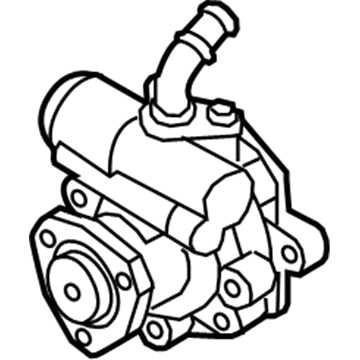

Volkswagen Passat Power Steering Pump

Choose OEM Power Steering Pump for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Power Steering Pump on your Passat, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Passat parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Passat Power Steering Pump Parts and Q&A

- Q: What steps should be followed to replace the power steering pump on Volkswagen Passat?A:The models also have an anti-theft radio installed and as such you must remember to have the activation code before disconnecting the battery. The disconnection of the battery may cause problems in driveability that may need to be fixed with the help of a scan tool, and they may also activate warning lights on the instrument panel, which may need to be recessed using a scan tool. The majority of the popular scan tools do not have the features to do these tasks and this would involve going to one of the dealer service departments or a well equipped repair facility in a post-service work pay. The first step is to remove the cable, which is connected to the negative side of the battery, and then disconnect the ribbed drivebelt. In case of four-cylinder models, it is necessary to raise the front of the car and place it firmly on jackstands, remove the under-vehicle splash shield and the front bumper then work out the radiator support panel to the service position. Then unscrew the water pump pulley and drivebelt, clamp the supply and return hose around the power steering fluid reservoir to stop the maximum possible loss of fluid, and clean around the power steering pressure and return line fittings. Unscrew the banjo bolt to disconnect the pressure line with the pump, and be ready in case of fluid spillage, and retrieve the sealing washers, discarding the old ones. To avoid leaking and contamination of the fluid, insert an end of the line and steering pump orifice. Loosen the clamp to needle the supply hose of fluid to the rear of the power steering pump, then loosen the mounting bolts of the pump in order to lose the pump to its mounting bracket. In the event that the power steering pump is malfunctioning, then it needs to be change since it is a sealed unit. When a new pump is installed, it should be filled with fluid to provide adequate lubrication when turning the pump pulley to allow the specified grade of hydraulic fluid to pass through the fluid supply port until it comes out of the pressure port. Install and attach the mounting bolts after arranging the pump in place, attach the pressure line with new sealing washers and place the supply hose in the clip. Install the water pump pulley and drivebelt, radiator support panel, and the front bumper, and install the under-vehicle splash shield, and reassemble the negative battery cable. Lastly, fill the hydraulic system and bleed the system. In V6s, the steps include the following: take off the top engine cover, label the location of the spark plug wires, and take off the ignition coil set. To remove the tension on the pulley to allow it not to revolve, a strap or chain wrench is used to detach the pulley with the pump, and connect the pressure line and fluid supply hose as mentioned before. Disassemble the pump and bracket by removing pump bracket mounting bolts so as to remove the pump and the bracket off of the engine, and part the pump apart with the bracket. Repeat the priming and installation process of the new pump, re-connection of the pressure line and supply hose and the re-fitment of the pulley, ignition coil assembly and engine top cover. Refit the negative battery cable, fill up the hydraulic system and bleed the system.

Related Volkswagen Passat Parts

Browse by Year

2014 Power Steering Pump 2013 Power Steering Pump 2012 Power Steering Pump 2005 Power Steering Pump 2004 Power Steering Pump 2003 Power Steering Pump 2002 Power Steering Pump 2001 Power Steering Pump 2000 Power Steering Pump 1999 Power Steering Pump 1998 Power Steering Pump 1997 Power Steering Pump 1996 Power Steering Pump 1995 Power Steering Pump 1994 Power Steering Pump 1993 Power Steering Pump 1992 Power Steering Pump 1991 Power Steering Pump 1990 Power Steering Pump