×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

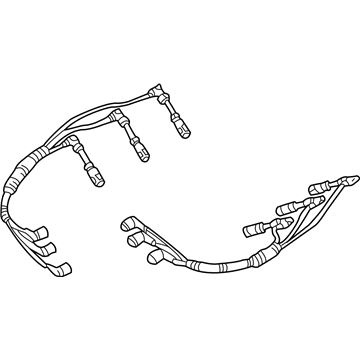

Genuine Volkswagen Spark Plug Wire

Spark Plug Ignition Wires- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

50 Spark Plug Wires found

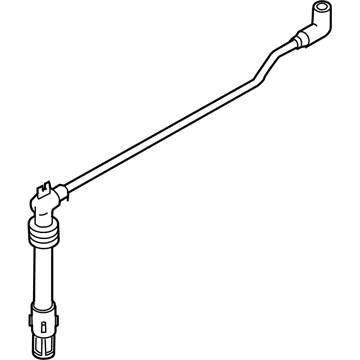

Volkswagen Plug Wire Part Number: 021-905-430-DF

$40.31 MSRP: $55.99You Save: $15.68 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cable

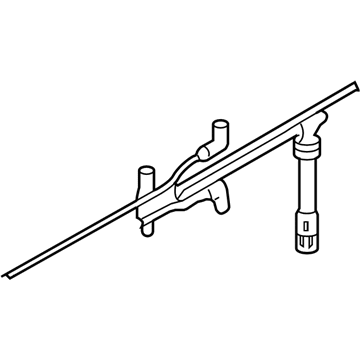

Volkswagen Cable Part Number: 06A-905-430-AC

$48.47 MSRP: $67.32You Save: $18.85 (28%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 06A-905-430-J

Volkswagen Cable Part Number: 06A-905-430-AD

$48.47 MSRP: $67.32You Save: $18.85 (28%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 06A-905-430-K

Volkswagen Cable Part Number: 06A-905-430-AE

$48.47 MSRP: $67.32You Save: $18.85 (28%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 06A-905-430-L

Volkswagen Cable Part Number: 06A-905-430-AF

$48.47 MSRP: $67.32You Save: $18.85 (28%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 06A-905-430-H, 06A-905-430-AG

Volkswagen Cable Part Number: 06A-905-430-AK

$48.47 MSRP: $67.32You Save: $18.85 (28%)Ships in 1-2 Business DaysVolkswagen Cable Part Number: 06A-905-430-AL

$48.47 MSRP: $67.32You Save: $18.85 (28%)Ships in 1-2 Business DaysVolkswagen Cable Part Number: 06A-905-430-AM

$48.47 MSRP: $67.32You Save: $18.85 (28%)Ships in 1-2 Business DaysVolkswagen Cable Part Number: 06A-905-430-AN

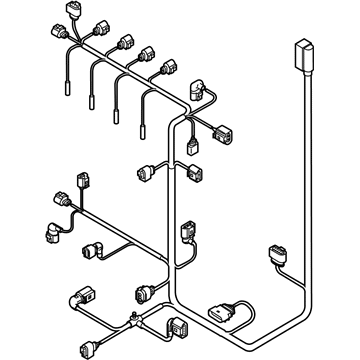

$48.47 MSRP: $67.32You Save: $18.85 (28%)Ships in 1-2 Business DaysVolkswagen Harness Part Number: 4G0-971-782

$45.35 MSRP: $62.99You Save: $17.64 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector; Harness

- Replaces: 07Z-971-782

Volkswagen Plug Wire Part Number: 021-905-430-DA

$50.15 MSRP: $69.66You Save: $19.51 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cable

- Replaces: 021-905-430-BM

Volkswagen Plug Wire Part Number: 021-905-430-DC

$60.68 MSRP: $84.98You Save: $24.30 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cable

Volkswagen Plug Wire Part Number: 021-905-430-DD

$60.68 MSRP: $84.98You Save: $24.30 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cable

- Replaces: 021-905-430-BQ

Volkswagen Plug Wire Part Number: 021-905-430-DE

$50.15 MSRP: $69.66You Save: $19.51 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cable

- Replaces: 021-905-430-BR

Volkswagen Cable Part Number: N-103-164-04

$57.11 MSRP: $79.32You Save: $22.21 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plug Wire

Volkswagen Plug Wire Part Number: N-103-164-03

$57.26 MSRP: $79.54You Save: $22.28 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Cable

- Replaces: N-104-186-04

Volkswagen Cable Part Number: 078-905-531-B

$77.34 MSRP: $108.32You Save: $30.98 (29%)Ships in 1-2 Business DaysVolkswagen Cable Part Number: 078-905-532-B

$77.34 MSRP: $108.32You Save: $30.98 (29%)Ships in 1-2 Business DaysVolkswagen Cable Part Number: 078-905-533-B

$77.34 MSRP: $108.32You Save: $30.98 (29%)Ships in 1-2 Business DaysVolkswagen Cable Part Number: 078-905-535-B

$77.34 MSRP: $108.32You Save: $30.98 (29%)Ships in 1-2 Business Days

| Page 1 of 3 |Next >

1-20 of 50 Results

Volkswagen Spark Plug Wire

A total system failure could result from a malfunctioning Volkswagen Spark Plug Wire, reducing driving comfort and posing a danger. It is for this reason that you should conduct regular inspections and replace such components in good time to enable your car to run smoothly and safely. OEM (Original Equipment Manufacturer) Volkswagen Spark Plug Wires are perfect for motorists because they are the best quality parts produced as per the manufacturer's specifications; hence, they perform well and are reliable too, thus helping to retain the car's initial functionality as well as safety features. At VWPartsGiant.com, our genuine Volkswagen Spark Plug Wire supply indicates how much we care about the health of your vehicle. Additionally, our stock is vast, so every product will be easily accessible to you for finding and swapping without fear of making mistakes. With our user-friendly online catalog, it takes no time to identify the right spare part. Therefore, convenience accompanies servicing or maintaining a motorcar. You can rely on our OEM Volkswagen Spark Plug Wire to sustain the performance of your automobile.

Volkswagen Spark Plug Wire Parts and Q&A

- Q: How should spark plug wires be checked and maintained on Volkswagen Passat?A:Recommended intervals also require checking the spark plug wires as well as whenever new spark plugs are fitted in the engine. The first step is a visual inspection of the spark plug wires, which should be done when the engine is running in a dim garage with a good amount of ventilation. Turn on the starter and pay attention to every plug wire, making sure that you are not touching any parts of the engine that are in motion; a small spark or arc at a broken wire symbolizes a break. The engine is turned off, and the plug wire that is connected to one of the spark plugs is detached by holding the rubber boot, twisting it down a bit then pulling the wire off but not the wire itself. Look inside the boot, in place of corrosion would be white crusty powder, and be sure that the wire and boot are firmly in place on the spark plug, otherwise, with pliers, crimp the metal connector therein. Clean the wire length with a clean rag to get all the dirt and grease off, and see how many holes there are, areas burnt, any cracks and other damage, but do not over bend it. The wire connects the coil pack to the wire; pull it off with a boot pulling tool, if needed, and examine it to make sure that it is free of corrosion and fits the contact. Test the rest of the spark plug wires individually to make sure that they are firmly clamped on at each end. In case the new spark plug wires are required, then buy a set according to the engine model, but they have to be pre-cut and the rubber boots are already attached. Swap the wires sequentially so you do not confuse the firing order, mark the routing of each wire before disconnection and compare the old wires with the new wires to make appropriate replacements.

Related Volkswagen Parts

Browse by Model

Beetle Spark Plug Wire Cabrio Spark Plug Wire Cabriolet Spark Plug Wire Corrado Spark Plug Wire EuroVan Spark Plug Wire Fox Spark Plug Wire Golf Spark Plug Wire Jetta Spark Plug Wire Passat Spark Plug Wire Quantum Spark Plug Wire Rabbit Convertible Spark Plug Wire Rabbit Spark Plug Wire Routan Spark Plug Wire Scirocco Spark Plug Wire Vanagon Spark Plug Wire