×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

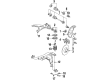

Genuine Volkswagen Brake Hose

Brake Line- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

84 Brake Hoses found

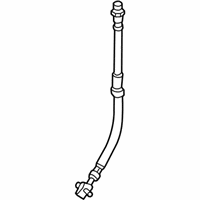

Volkswagen Flex Hose Part Number: 561-611-775-B

$33.47 MSRP: $55.78You Save: $22.31 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Flex Hose

Volkswagen Flex Hose Part Number: 1K0-611-775-D

$36.23 MSRP: $50.32You Save: $14.09 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Flex Hose

- Position: Left

Volkswagen Flex Hose Part Number: 1K0-611-776

$36.23 MSRP: $50.32You Save: $14.09 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Flex Hose

- Position: Right

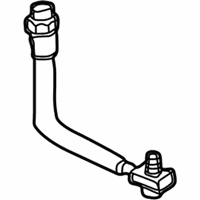

Volkswagen Brake Line Part Number: 1J0-614-750

$36.71 MSRP: $50.98You Save: $14.27 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flex Hose

- Position: Right

- Replaces: 1J0-611-764-R, 1J0-611-764-AD, 1J0-611-764-K

Volkswagen Flex Hose Part Number: 1Q0-611-775-D

$12.48 MSRP: $20.46You Save: $7.98 (39%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Flex Hose

- Replaces: 1Q0-611-775-A

Volkswagen Flex Hose Part Number: 5N0-611-701-A

$36.71 MSRP: $50.98You Save: $14.27 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Flex Hose

- Replaces: 5N0-611-701

Volkswagen Flex Hose Part Number: 5QM-611-701-C

$36.71 MSRP: $50.98You Save: $14.27 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose

Volkswagen Flex Hose Part Number: 5Q0-611-775-L

$37.31 MSRP: $51.82You Save: $14.51 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Brake Hose, Flex Hose

Volkswagen Brake Line Part Number: 3D0-614-763-G

$39.59 MSRP: $54.98You Save: $15.39 (28%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Volkswagen Flex Hose Part Number: 3QF-611-775-A

$39.59 MSRP: $54.98You Save: $15.39 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Brake Hose, Flex Hose

Volkswagen Flex Hose Part Number: 5C0-611-775-C

$39.59 MSRP: $54.98You Save: $15.39 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Flex Hose

- Position: Left

- Replaces: 561-611-775

Volkswagen Flex Hose Part Number: 5C0-611-775-E

$39.59 MSRP: $54.98You Save: $15.39 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Flex Hose

- Replaces: 5C0-611-775-D

Volkswagen Flex Hose Part Number: 5C0-611-776

$39.59 MSRP: $54.98You Save: $15.39 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Flex Hose

- Position: Right

- Replaces: 561-611-776

Volkswagen Brake Tube Part Number: 7P0-614-771-A

$19.51 MSRP: $31.98You Save: $12.47 (39%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Line

- Position: Left

- Replaces: 7P0-614-771

Volkswagen Brake Tube Part Number: 7P0-614-772-A

$19.51 MSRP: $31.98You Save: $12.47 (39%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Line

- Position: Right

Volkswagen Brake Line Part Number: 7L0-614-771-A

$24.71 MSRP: $41.18You Save: $16.47 (40%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

- Replaces: 7L0-614-771

Volkswagen Brake Line Part Number: 4B3-611-722-C

$24.34 MSRP: $39.90You Save: $15.56 (39%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

- Replaces: 4B3-611-722-B

Volkswagen Flex Hose Part Number: 1K0-611-775-C

$34.91 MSRP: $58.18You Save: $23.27 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose; Flex Hose

- Replaces: 1K0-611-775-A, 1K0-611-775, 3C0-611-775

Volkswagen Brake Line Part Number: 3D0-614-764-K

$36.59 MSRP: $50.82You Save: $14.23 (28%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

- Replaces: 3D0-614-764-G, 3D0-614-764-D

Volkswagen Hose Part Number: BAT-611-775

$12.08 MSRP: $19.80You Save: $7.72 (39%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Hose

| Page 1 of 5 |Next >

1-20 of 84 Results

Volkswagen Brake Hose

A total system failure could result from a malfunctioning Volkswagen Brake Hose, reducing driving comfort and posing a danger. It is for this reason that you should conduct regular inspections and replace such components in good time to enable your car to run smoothly and safely. OEM (Original Equipment Manufacturer) Volkswagen Brake Hoses are perfect for motorists because they are the best quality parts produced as per the manufacturer's specifications; hence, they perform well and are reliable too, thus helping to retain the car's initial functionality as well as safety features. At VWPartsGiant.com, our genuine Volkswagen Brake Hose supply indicates how much we care about the health of your vehicle. Additionally, our stock is vast, so every product will be easily accessible to you for finding and swapping without fear of making mistakes. With our user-friendly online catalog, it takes no time to identify the right spare part. Therefore, convenience accompanies servicing or maintaining a motorcar. You can rely on our OEM Volkswagen Brake Hose to sustain the performance of your automobile.

Volkswagen Brake Hose Parts and Q&A

- Q: How to effectively inspect and replace brake hoses and metal brake lines in a vehicle's brake system on Volkswagen Jetta?A:Check the rubber hoses connecting the steel brake lines with the front and rear brake assemblies once a year, when the vehicle is raised and is well supported on jackstands, to identify cracks, chafing, leakages, blisters, and other damage to the rubber hose since they are vital parts of the brake system. Conduct a proper examination with a light and a mirror and remove any hose that demonstrates wear. In the case of the front brake hose, slacken the wheel bolts, lift the vehicle and take off the wheel. Record the installation of the hose fitting tabs on the frame bracket to stop twisting. Slide a hose-fitting in an open-end into place and loosen a brake line-fitting with a flare-nut wrench without rounding the nut but ensure the spring clip is not lost. Unscrew the brake hose by unscrewing the inlet fitting bolt and casting off the old sealing washers. Unclip the spring on the bracket on the lower end of the strut and pull the hose out of the bracket. Installation steps included installing the new hose into a bracket, attaching the spring clip using new sealing washers and not twisting the hose then tightening the caliper inlet fitting bolt. Install the brake line fitting by connecting the hose at which point you start the threads by hand followed by adding the spring clip and snapping it in place. In the case of the rear brake hose, which has an opening at each end that is held together by a spring clip, hold the hose fitting open by an open-end wrench and unscrew the brake line fitting, removing the spring clip with pliers. On the caliper end, attach the hose fitting with a flare nut wrench and then connect and tighten it. In the case of rear drum brakes, unscrew the brake line connection out of the wheel cylinder, disassemble the line out of the plastic clips attached to it along the rear axle, and pull it out of the car. Installation is the opposite of removal; make sure that the line is tightened and bleed the caliper or wheel cylinder to which the replaced line was connected. Brake lines in metal replacement should be of pure steel and not copper tubes. Ready-made brake lines with flared tube ends are sold in auto parts shops, as well as fittings installed. Make sure that the new line is firmly held in brackets with sufficient clearance of the moving or hot parts. Once it has been installed, check the level of the master cylinder fluid, fill it when needed, bleed the brakes and test the brakes before driving.

- Q: How often should you inspect the brake hose connecting the steel brake lines with the brake assemblies on Volkswagen Passat?A:The rubber hoses of the steel brake lines should be inspected at a regular rate of about every six months, with the vehicle elevated and placed upon jackstands, to check cracks, chafing, leaks, blisters and other damage in the hoses, since they are vital components of the brake system. A check will be conducted properly with the help of a light and a mirror, and hoses with traces of wear must be changed. To reduce wastage of fluid during replacement of any pipe/ hose, place the polyethylene over the top of the master cylinder reservoir before fitting it or screw a brake hose before clamping a brake hose and then plug or cap metal brake line fittings immediately after disconnection. Put any rag under any appropriate fitting to prevent any spilled fluid and when removing a flexible hose, unscrew brake line fitting and remove spring clip where the hose is attached. The fitting nuts should be unscrewed with a flare nut wrench, to prevent rounded off corners, and the fitting and the surrounding place should be cleaned. Where a component has a number of fittings, record the connections carefully in case it is removed. Replacing metal brake lines, replace with the correct parts not with copper tubing, and use prefabricated brake lines, which are sold by auto parts stores and have to be curved to the right shapes. Make sure that the new line is well bracketed with a clearance of moving or hot parts and should not overtighten fitting nuts. Ensure that the pipes and hoses are properly laid without kinking and fixed in the supplied clips or brackets. Once installed, drain the hydraulic system by removing the polyethylene sheet in the reservoir, wash and dry any spill in the hydraulic system with water and leaks.

Related Volkswagen Parts

Browse by Model

Arteon Brake Hose Atlas Brake Hose Atlas Cross Sport Brake Hose Beetle Brake Hose CC Brake Hose Cabrio Brake Hose Cabriolet Brake Hose Corrado Brake Hose Eos Brake Hose EuroVan Brake Hose Fox Brake Hose GTI Brake Hose Golf Alltrack Brake Hose Golf Brake Hose Golf R Brake Hose Golf SportWagen Brake Hose ID.4 Brake Hose Jetta Brake Hose Passat Brake Hose Phaeton Brake Hose Quantum Brake Hose R32 Brake Hose Rabbit Brake Hose Routan Brake Hose Scirocco Brake Hose Taos Brake Hose Tiguan Brake Hose Tiguan Limited Brake Hose Touareg Brake Hose Vanagon Brake Hose e-Golf Brake Hose