×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen GTI Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Boosters found

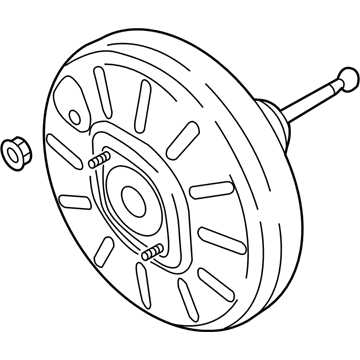

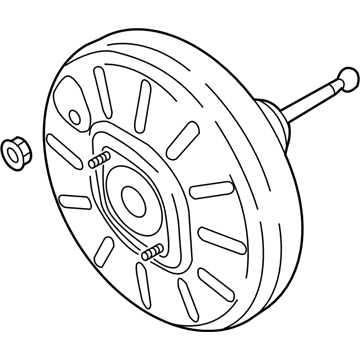

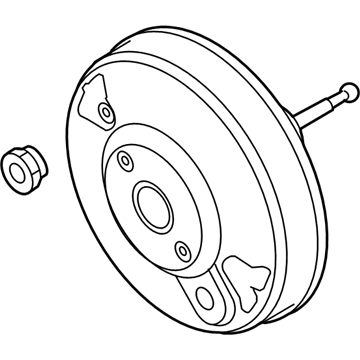

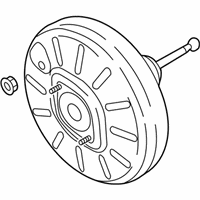

Volkswagen GTI Brake Booster Part Number: 5Q1-614-106-Q

$236.80 MSRP: $331.65You Save: $94.85 (29%)Ships in 1-2 Business DaysVolkswagen GTI Brake Booster Part Number: 5QM-614-106-D

$56.29 MSRP: $78.18You Save: $21.89 (28%)Ships in 1-2 Business DaysVolkswagen GTI Brake Booster Part Number: 8V1-612-107-A

$301.94 MSRP: $412.49You Save: $110.55 (27%)Ships in 1-2 Business DaysVolkswagen GTI Brake Booster Part Number: 1K1-614-106-AB

$338.54 MSRP: $462.49You Save: $123.95 (27%)Ships in 1-2 Business Days

Volkswagen GTI Brake Booster

Choose OEM Brake Booster for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Brake Booster on your GTI, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen GTI parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen GTI Brake Booster Parts and Q&A

- Q: What precautions should be taken when disconnecting the battery and replacing the power brake booster on Volkswagen GTI?A:This should be done with care because when the battery is disconnected, there are a number of systems that will have to be re-learned in order to be used correctly. Some models have an automatic transaxle, where a Vacuum Pump supplies vacuum to the power brake booster along with manifold vacuum, installed close to the ABS/ESP hydraulic unit that supplies a vacuum hose to the brake booster. A dealer service department or qualified repair shop should perform diagnosis in case the system appears defective since the power brake booster is not serviceable and should be replaced in case it is faulty. The power brake booster is taken off as one piece together with the master cylinder. To carry out an operating check, press and release the brake pedal several times with the engine off to confirm that there is no change in the peddle reserve distance after which, the engine can be started and a slight drop in the peddle indicates that the system operates properly. To check the airtightness, begin the engine and turn it off after one to two minutes, depressing the brake pedal slowly a few times; the reduction in the amount of the pedal depression means that the booster is airtight. Turn the engine off, multiple presses on the brake pedal, remove the engine cover, separate the negative battery terminal, and pull out the battery and tray. Also to be removed are the driver side knee bolster, brake light switch and the removal of the booster pushrod off the brake pedal with a special tool that has been made. The master cylinder and vacuum hose attached to the brake booster located within the engine compartment is to be removed, clips, and any sound insulation panels. In models with a manual transaxle, the shift cables and brackets must be removed, whereas when it is an automatic transaxle, the transmission cooler line must be clamped and disconnected. The bottom trim panel and booster mounting nuts are removed in the car, the brake booster removed off the firewall, then the cowl compartment is detached and separated with the master cylinder. Installation: Assemble the master cylinder with the power brake booster when installing, making sure that the pushrod fits in correctly; and remove them in the part of the sequence that they were installed in. All mounting fasteners must be tightened to the torque values mentioned and to bleed the master cylinder an assistant must pump the brake pedal and hold it to the floor, loosening line fittings until none more air and fluid passes through at all. Enough rags to receive any leakage of brake fluid, which may damage painted surfaces should be available and once the brake system has been bled, the brakes should be put into operation to ensure the vehicle is set back to normal service. Also, on those models that have a manual transaxle, the clutch system will need bleeding as well as the brake system.