×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

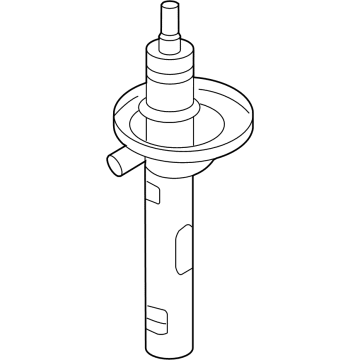

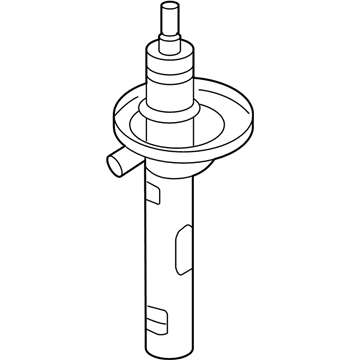

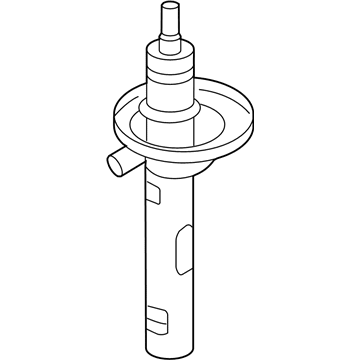

Genuine Volkswagen GTI Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Shock Absorbers found

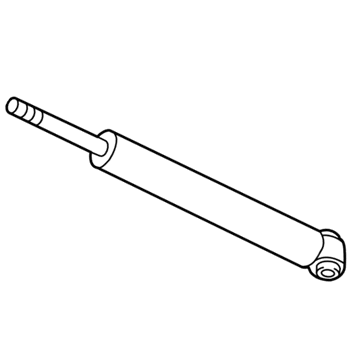

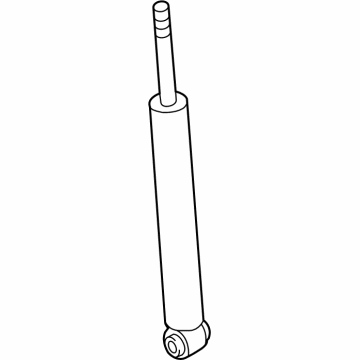

Volkswagen GTI Shock Part Number: 1K0-513-029-FA

$123.32 MSRP: $172.71You Save: $49.39 (29%)Ships in 1-2 Business DaysVolkswagen GTI Shock Part Number: 1K0-513-029-GP

$123.32 MSRP: $172.71You Save: $49.39 (29%)Ships in 1-2 Business DaysVolkswagen GTI Shock Absorber Part Number: 1K0-513-029-HL

$117.44 MSRP: $164.49You Save: $47.05 (29%)Ships in 1-2 Business DaysVolkswagen GTI Shock Part Number: 5QM-513-029-M

$132.51 MSRP: $185.57You Save: $53.06 (29%)Ships in 1-2 Business DaysVolkswagen GTI Shock Part Number: 5WA-513-029-BC

$132.51 MSRP: $185.57You Save: $53.06 (29%)Ships in 1-2 Business DaysVolkswagen GTI Strut Part Number: 5Q0-413-031-FN

$146.93 MSRP: $205.79You Save: $58.86 (29%)Ships in 1-2 Business DaysVolkswagen GTI Strut Part Number: 1T0-413-031-EQ

$162.67 MSRP: $227.84You Save: $65.17 (29%)Ships in 1-2 Business DaysVolkswagen GTI Strut Part Number: 5QM-413-031-E

$179.74 MSRP: $251.72You Save: $71.98 (29%)Ships in 1-2 Business DaysVolkswagen GTI Strut Part Number: 5WA-413-032-AA

$256.90 MSRP: $350.95You Save: $94.05 (27%)Ships in 1-2 Business DaysVolkswagen GTI Shock Part Number: 5WA-513-045-AM

$299.27 MSRP: $408.82You Save: $109.55 (27%)Ships in 1-2 Business DaysVolkswagen GTI Shock Part Number: 5Q0-513-045-AK

$470.76 MSRP: $643.11You Save: $172.35 (27%)Ships in 1-2 Business DaysVolkswagen GTI Strut Part Number: 5Q0-413-031-FM

$575.00 MSRP: $785.51You Save: $210.51 (27%)Ships in 1-2 Business Days

Volkswagen GTI Shock Absorber

Choose OEM Shock Absorber for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Shock Absorber on your GTI, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen GTI parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen GTI Shock Absorber Parts and Q&A

- Q: How to replace the rear shock absorbers on Volkswagen GTI?A:Unscrew the rear wheel bolts and chock the front wheels so that the vehicle does not roll and then use the jackstands to raise the rear and hold it firmly in place before the rear wheel is removed. In the case of models which have multi-link rear suspension, hold the lower Control Arm using a floor jack at a position close to the end of the arm as compared to those which have torsion beam rear axle whereby, the floor jack is placed below the coil spring pocket and should not be moved during the process. Use the removal of shock absorber lower mounting fastener, then the upper mounting fasteners to remove the shock absorber. Install the new shock absorber and install the upper mounting bolt; and a new lower mounting bolt (and nut, if present), but do not tighten the lower mounting fastener(s) at this point. Make sure to screw tight the upper mounting bolts to the required torque and lift the rear suspension to the normal ride height and screw tight the lower mounting bolt/nut to the required torque. Do the same thing with the other rear shock absorber and next fit the wheels and lower the car, tighten the wheel bolts to the torque required.

- Q: What actions are necessary if the coil springs and shock absorber in the front suspension strut show signs of wear on Volkswagen GTI?A:When the front suspension strut or coil springs have any signs of wear, i.e. leaking fluid, loss of damping ability, sagging or cracked coil springs etc., then they should be disassembled and overhauled accordingly, with the struts being replaced when defective and springs and associated parts being replaced separately so as to ensure an equal amount of characteristics on each side of the vehicle. Once the assembly is out of the vehicle, wipe off all the dirt on the outside and place it in a vise. Attach the tools of coil spring compressor and compress the spring until the upper mount releases all its tension. Use an Allen key to remove the strut piston rod and a box-end wrench to remove the nut securing the thrust bearing and then remove the top mount, upper spring seat, spring, boot, bearing and bump stop. When a new spring is required, be careful when removing the old spring out of the compressor; when re-using, it is not necessary to remove it out of the compressor. All the strut components should be checked to determine whether it is worn out and damaged and all the strut components should be repaired or replaced with some parts as needed with the strut assembly fully disassembled. Check the strut leakage, examine the pitting on the piston rod, and examine the damage or non-damage of the strut body. Test the operation of the strut by swinging the piston in long and short strokes, making sure of smooth and continuous resistance; a sudden or irregular resistance or wear visible on the strut is enough evidence of wear to get a replacement. The process of reassembly is the opposite of disassembly, where the coil springs should be fitted with the paint mark at the bottom, and the ends of the coil springs fit into the upper and lower seats correctly before the compressor is released and the piston rod nut tightened to the recommended torque.

Related Volkswagen GTI Parts

Browse by Year

2024 Shock Absorber 2023 Shock Absorber 2022 Shock Absorber 2021 Shock Absorber 2020 Shock Absorber 2019 Shock Absorber 2018 Shock Absorber 2017 Shock Absorber 2016 Shock Absorber 2015 Shock Absorber 2014 Shock Absorber 2013 Shock Absorber 2012 Shock Absorber 2011 Shock Absorber 2010 Shock Absorber 2009 Shock Absorber 2008 Shock Absorber 2007 Shock Absorber 2006 Shock Absorber