×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

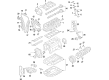

Genuine Volkswagen GTI Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

33 Engine Mounts found

Volkswagen GTI Support Part Number: 1K0-199-588

$13.65 MSRP: $22.38You Save: $8.73 (40%)Ships in 1-2 Business DaysVolkswagen GTI Support Part Number: 5Q0-199-517-G

$15.36 MSRP: $25.18You Save: $9.82 (39%)Ships in 1-2 Business DaysVolkswagen GTI Support Part Number: 5Q0-199-518-G

$15.36 MSRP: $25.18You Save: $9.82 (39%)Ships in 1-2 Business DaysVolkswagen GTI Support Part Number: 5Q0-199-517-D

$18.04 MSRP: $29.57You Save: $11.53 (39%)Ships in 1-2 Business DaysVolkswagen GTI Support Part Number: 5Q0-199-517-E

$18.04 MSRP: $29.57You Save: $11.53 (39%)Ships in 1-2 Business DaysVolkswagen GTI Support Part Number: 5Q0-199-518-D

$18.04 MSRP: $29.57You Save: $11.53 (39%)Ships in 1-2 Business DaysVolkswagen GTI Support Part Number: 5Q0-199-518-E

$18.04 MSRP: $29.57You Save: $11.53 (39%)Ships in 1-2 Business DaysVolkswagen GTI Bushings Part Number: 1K0-199-867-Q

$72.46 MSRP: $101.49You Save: $29.03 (29%)Ships in 1-2 Business DaysVolkswagen GTI Bushings Part Number: 1K0-199-868-Q

$72.46 MSRP: $101.49You Save: $29.03 (29%)Ships in 1-2 Business DaysVolkswagen GTI Engine Bracket Part Number: 1K0-802-068-A

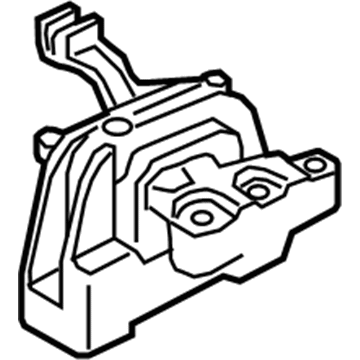

$27.88 MSRP: $46.46You Save: $18.58 (40%)Ships in 1-2 Business DaysVolkswagen GTI Support Part Number: 06K-199-207-A

$75.43 MSRP: $105.66You Save: $30.23 (29%)Ships in 1-2 Business DaysVolkswagen GTI Mount Part Number: 5Q0-802-068

$91.62 MSRP: $128.32You Save: $36.70 (29%)Ships in 1-2 Business DaysVolkswagen GTI Mount Part Number: 5Q0-810-811

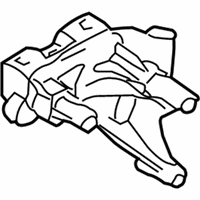

$91.62 MSRP: $128.32You Save: $36.70 (29%)Ships in 1-2 Business DaysVolkswagen GTI Hinge Support Part Number: 5Q0-199-855-AG

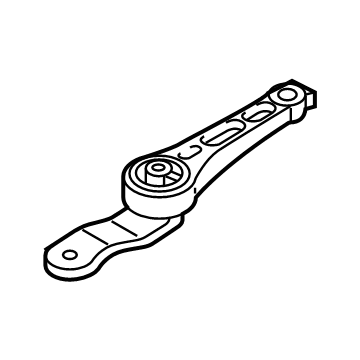

$171.35 MSRP: $239.98You Save: $68.63 (29%)Ships in 1-2 Business DaysVolkswagen GTI Arm Support Part Number: 5Q0-199-855-N

$85.67 MSRP: $119.99You Save: $34.32 (29%)Volkswagen GTI Bushings Part Number: 5Q0-198-037

$97.45 MSRP: $136.49You Save: $39.04 (29%)Ships in 1-2 Business DaysVolkswagen GTI Mount Part Number: 5Q0-198-037-A

$97.45 MSRP: $136.49You Save: $39.04 (29%)Ships in 1-2 Business DaysVolkswagen GTI Mount Part Number: 5Q0-198-037-F

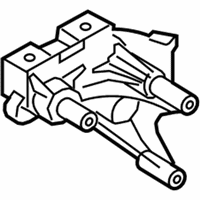

$97.45 MSRP: $136.49You Save: $39.04 (29%)Ships in 1-2 Business DaysVolkswagen GTI Mount Part Number: 5Q0-199-555-BK

$101.20 MSRP: $141.74You Save: $40.54 (29%)Ships in 1-2 Business DaysVolkswagen GTI Mount Part Number: 5Q0-199-262-BK

$99.91 MSRP: $139.93You Save: $40.02 (29%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 33 Results

Volkswagen GTI Engine Mount

Choose OEM Engine Mount for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Engine Mount on your GTI, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen GTI parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen GTI Engine Mount Parts and Q&A

- Q: Do engine mounts seldom require attention, and should broken or deteriorated mounts be replaced immediately to prevent damage or wear on driveline components for 4-cylinder engines on Volkswagen GTI?A:Engine mounts are not very urgent, however, broken or worn out mounts must be replaced as soon as possible to avoid the damage or wear of the drive line parts. When checking, the engine should be elevated slightly so as to eliminate the weight to the mounts. Lift the vehicle up and place it in jackstands and place a jack under the engine oil pan with a large block of wood between the jack head and the oil pan and take pains to raise the engine just high enough to clear the weight off the mounts. Take out the splash shield beneath the engine, when it has one, and examine the mounts, whether they are cracked, hardened rubber, or are separating off the metal plates, and record any fissures. verify relative movement of the mount plates and engine or frame with large screwdriver or pry bar; when relative movement found, have engine lowered and mount fasteners tightened. To replace, position the vehicle and place it on jackstands, and then support the engine. Disassemble the under-vehicle splash shield and in certain models, the bracket of the exhaust system may have to be pulled out of the subframe. Unscrew the pendulum mount-to-subframe bolt, the pendulum-to-transmission bolts and drag the pendulum mount out of the subframe. Install the new pendulum mount into the subframe, with the first step being to install the transmission-to-pendulum bolts followed by the pendulum-to-subframe bolt and tightening the bolts to the desired torque, and lastly, installing the splash shield. Unhook the cable on the negative terminal of the battery and then, still working in the engine compartment, carefully loosen the engine cover working on the top of the engine. The replacement procedure on a driver side transmission mount is specific. In the passenger side engine mount, unscrew the coolant reservoir and place it aside without disconnection of the hoses and then take out the EVAP canister. To remove the engine mount, have the engine at rest with some support above or below and then with the engine and transmission in place, loosen the engine mount-to-body fasteners and engine mount-to-engine mount bracket fasteners one after another. Install the new mount and retaining fasteners, hand-tightening and subsequent to tightening all the fasteners to the recommended torque and installation is the opposite of the removal operation.

- Q: What should be done if engine mounts are broken or deteriorated for 5-cylinder engines on Volkswagen GTI?A:Engine mounts do not need much work, however, damaged or worn mounts are to be replaced as soon as possible to avoid harm or wear on the components of the drive line. When the check is being performed one should lift the engine a notch so that it is not put on the mounts. Lift the vehicle and place it on jackstands, and place a jack beneath the engine Oil Pan, a large block of wood between the jack head and the engine to avoid damaging the engine and carefully lifting the engine until it is higher than the mounts take the weight off them. Examine the mounts to check on the occurrence of cracks, hardening of rubber or detachment of the rubber to the bushing in the center. Test relative motion of the mount with the engine or chassis with a large screwdriver, or pry bar; relative motion present, reduce the engine and tighten the mount fasteners. When the battery is disconnected, a number of systems would have to be learned again before they could start functioning again. Lift the vehicle, and place it safely on jackstands (unless already done), and support the engine as mentioned above. Take away the splash shield of the under-vehicle. In the case of the pendulum support mount, unscrew the pendulum mount-to-subframe bolt then the pendulum-to-transmission bolts and bracket. Take out the pendulum mount subframe, and take out the pendulum support. Install the pendulum mount into the sub frame and the bracket and transmission-to-pendulum bolt, and finally the pendulum-to-subframe bolt, screwing them to the correct torque. Lastly, fit on the splash shield. To lift the engine on the passenger side, disassembly of the heat shield on the inboard joint of the right driveaxle is needed. To be able to work in an engine compartment, working on the top, take off the engine cover/air filter housing and the coolant reservoir, but it may be necessary to take off the windshield washer reservoir depending on the model. Wood block Place a floor jack under the engine, with the jack head resting between the oil pan and the mounts to take the weight off the mounts. Disassemble the support bracket and mount and engine, and then the reverse of the previous process is to reassemble them onto the body and engine, with thread-locking compound on the mount bolts and screw them firmly in.

Related Volkswagen GTI Parts

Browse by Year

2024 Engine Mount 2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2014 Engine Mount 2013 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount