×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Passat CV Joint Boot

Constant-Velocity Joint Boot- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

27 CV Joint Boots found

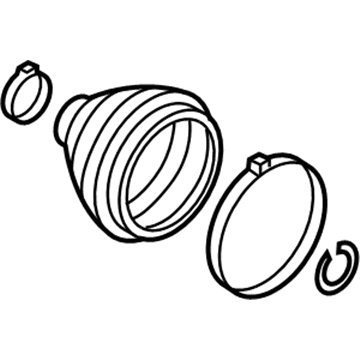

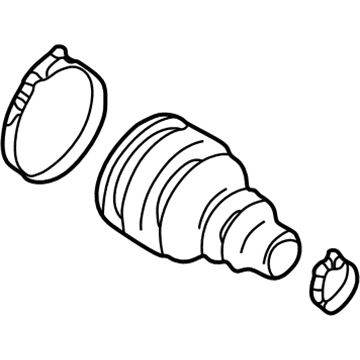

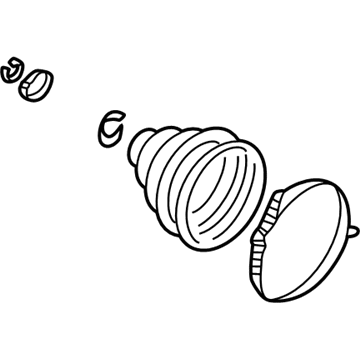

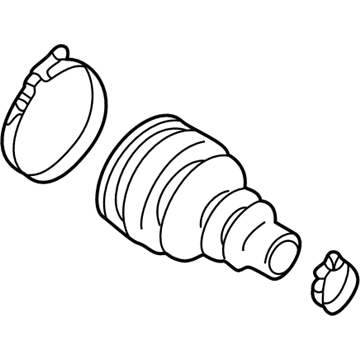

Volkswagen Passat Boot Kit Part Number: 1H0-498-203-A

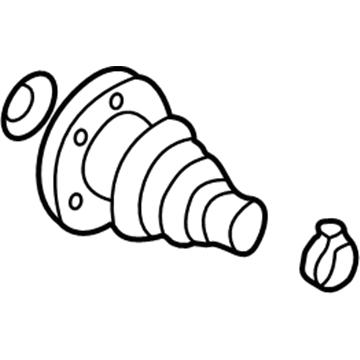

$30.41 MSRP: $50.68You Save: $20.27 (40%)Ships in 1-2 Business DaysVolkswagen Passat Inner Boot Part Number: 8D0-498-201

$34.20 MSRP: $57.00You Save: $22.80 (40%)Ships in 1-2 Business DaysVolkswagen Passat Boot Kit Part Number: 357-498-202

$34.61 MSRP: $57.68You Save: $23.07 (40%)Ships in 1-2 Business DaysVolkswagen Passat Inner Boot Part Number: 1K0-498-201

$35.88 MSRP: $59.80You Save: $23.92 (40%)Ships in 1-2 Business DaysVolkswagen Passat Outer Boot Part Number: 1K0-498-203

$7.82 MSRP: $12.82You Save: $5.00 (39%)Ships in 1-2 Business DaysVolkswagen Passat Outer Boot Part Number: 1K0-498-203-A

$12.59 MSRP: $20.64You Save: $8.05 (39%)Ships in 1-2 Business DaysVolkswagen Passat Inner Boot Part Number: 3Q0-498-201

$13.85 MSRP: $22.70You Save: $8.85 (39%)Ships in 1-2 Business DaysVolkswagen Passat Boot Kit Part Number: 1H0-498-203

$24.01 MSRP: $33.35You Save: $9.34 (29%)Ships in 1-2 Business DaysVolkswagen Passat Outer Boot Part Number: 3B0-598-203

$39.60 MSRP: $55.00You Save: $15.40 (28%)Ships in 1-2 Business DaysVolkswagen Passat Outer Boot Part Number: 4B0-598-203

$40.80 MSRP: $56.67You Save: $15.87 (28%)Ships in 1-2 Business DaysVolkswagen Passat Boots Part Number: 7L0-498-203

$40.80 MSRP: $56.67You Save: $15.87 (28%)Ships in 1-2 Business DaysVolkswagen Passat Inner Boot Part Number: 1KM-498-201

$41.27 MSRP: $57.32You Save: $16.05 (28%)Ships in 1-2 Business DaysVolkswagen Passat Boot Kit Part Number: 357-498-201

$42.28 MSRP: $58.72You Save: $16.44 (28%)Ships in 1-2 Business DaysVolkswagen Passat Boots Part Number: 3B0-498-203-A

$43.20 MSRP: $60.00You Save: $16.80 (28%)Ships in 1-2 Business DaysVolkswagen Passat Outer Boot Part Number: 441-498-203-A

$48.00 MSRP: $66.67You Save: $18.67 (28%)Ships in 1-2 Business DaysVolkswagen Passat Inner Boot Part Number: 1K0-498-201-D

$60.68 MSRP: $84.98You Save: $24.30 (29%)Ships in 1-2 Business DaysVolkswagen Passat Inner Boot Part Number: 443-498-201-B

$51.98 MSRP: $72.20You Save: $20.22 (29%)Ships in 1-2 Business DaysVolkswagen Passat Outer Boot Part Number: 4A0-498-203-C

$74.96 MSRP: $104.98You Save: $30.02 (29%)Ships in 1-2 Business DaysVolkswagen Passat Inner Boot Part Number: 4B0-498-201

$76.15 MSRP: $106.65You Save: $30.50 (29%)Ships in 1-2 Business DaysVolkswagen Passat Inner Boot Part Number: 893-498-201-B

| Page 1 of 2 |Next >

1-20 of 27 Results

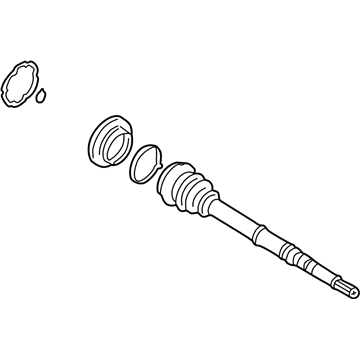

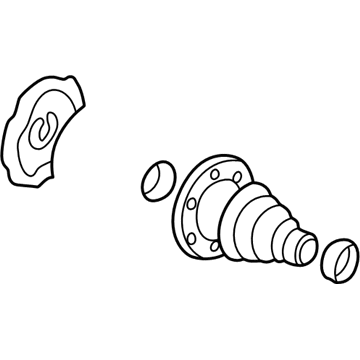

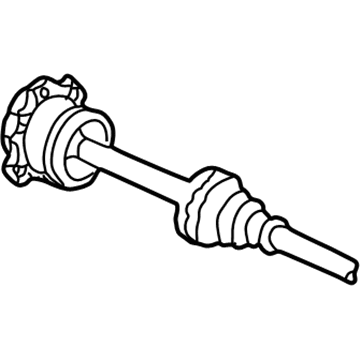

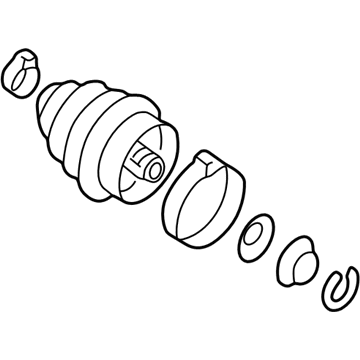

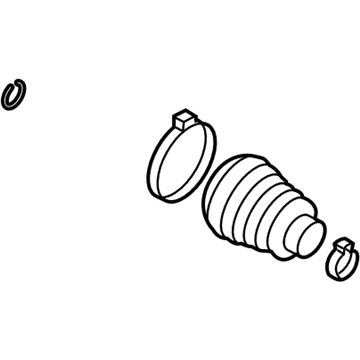

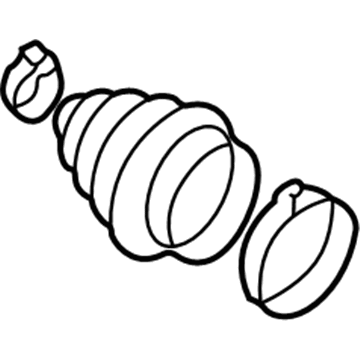

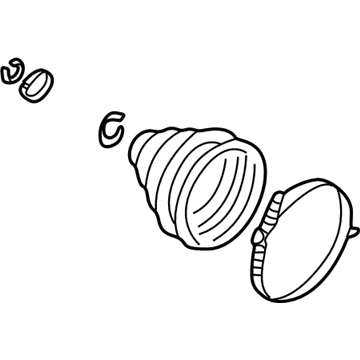

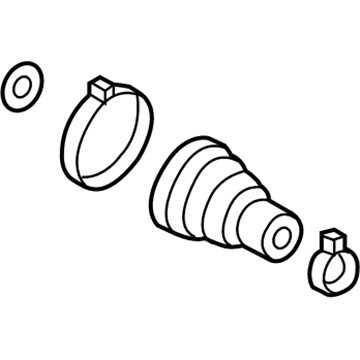

Volkswagen Passat CV Joint Boot

Choose OEM CV Joint Boot for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace CV Joint Boot on your Passat, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Passat parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Passat CV Joint Boot Parts and Q&A

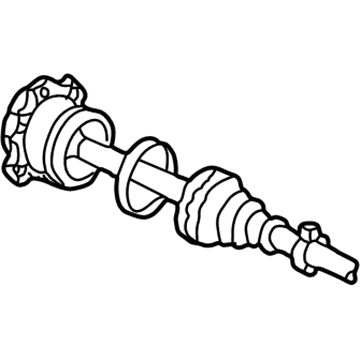

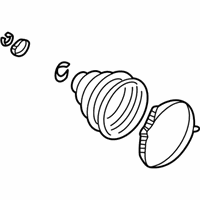

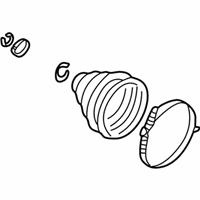

- Q: How to remove and reassemble a driveaxle with a CV Joint Boot on Volkswagen Passat?A:In order to pull the driveaxle out of the vehicle, hold it in a vise using soft jaws, and unscrew the two outer joint boot clamps and cut them off. Slide the boot down the shaft and wipe the excess grease off the constant velocity (CV) joint. Tap the joint off the end of the driveaxle with a hammer and brass punch, the punch should only make contact with the inner race. Unscrew the circlip of the driveaxle groove, then push away the thrust washer and dished washer, recording their position of installation. Wipe off the boot and clean the outer CV joint assembly and note the relative positions of the bearing cage, inner race and housing. Install the outer CV joint into a vise, compress one side of the cage, and remove all the ball bearings with a hammer and brass punch in case the joint is tight. Take out the cage and inner race assembly by tilting the assembly and aligning cage windows with ball grooves. Swivel out the inside race by turning it 90 degrees to face a cage window. Clean every component using solvent, check out any damage or wear; when any parts cannot be serviced, replace the relatable CV joint assembly. When the joint is satisfactory, take a replacement kit of boots which usually consists of a new boot, retaining clamps, snap-ring, and grease. Apply grease to all the CV joint components and then reassemble, replace the inner race in the cage and center the marks. Install inner race and cage assembly into the CV joint housing whereby the assembly aligns with the mark on the housing. Install the balls together, (one at a time), and grease the joint with a wooden dowel through the hole in the inner race. Install the axleshaft by placing it in the vise and cleaning the end then inserting the new clamp and boot, wrapping the splines in electrical tape to prevent damage of boots. Take off the protective tape on the splines of the driveaxle and slide the dished washer and thrust washer onto the splines, place on a new circlip and tap the joint into the driveaxle till the circlip makes contact. Slide the boot around the joint, but be careful that the lips of the boot are not twisted upside down and place the large retaining clamp, tightening it with a clamp crimping tool. Make sure that the constant velocity joint is moving freely and then install the driveaxle. In the case of inner CV joint, take away and dispose the boot clamps, and then tug the boot back up the shaft. Install the driveaxle in a vise, remove the cover, and the O-ring. Indicate the connections of the housing, triple-rotor spider, and axleshaft and take out the axleshaft and slide it down the shaft. Insert the snap-ring and slide the spider off the shaft, with the aid of a hydraulic press, where needed. Wash down all parts, and examine to see whether they are worn or not; in case of wear, change the joint. Install the small clamp and boot, slide the joint housing over the shaft and wrap the splines with electrical tape. Go with the marks and fit a new snap-ring. Lubricate the spider posts and put up the rollers greasing them up. Lay the housing into place on the spider, hold the housing in the vise, and place in the square section O-ring. Apply the right quantity of CV joint grease in the joint, and then fix the boot and clamps without twisting them. Lastly, make sure that the constant velocity joint is completely free then install the driveaxle. In the case of the ball-and-cage type joint, take out the boot clamp, hold the driveaxle in a vise and knock the boot cap out. Take the snap-ring out and pull the inner joint out of the axleshaft, with a hammer and brass punch as may be necessary. Wipe off the joint and indicate the connections between the inner race, cage and housing. Turn the cage and inner race to get them out, and then get out each ball bearing, marking the positions. Wipe everything down and check for wear; it may need a replacement of the joint. Grease the parts, then put in the inner race and cage and squeeze in the ball bearings. Install the inner race, cage, and balls into the housing while ensuring that it is aligned. Install the new boot and clamp, covering the splines with electrical tape. Take off the tape, fit in the dished washer and make adjustments to the boot where necessary. Apply grease to the CV joint, taking care to use the required quantities in various models, and put the top of the boot upon the joint housing. Wipe the joint housing surface and apply a new gasket to it, keeping the constant velocity joint freely moving and then attach the driveaxle.

- Q: How often should the CV Joint Boot be checked to prevent excessive tire wear and handling issues on Volkswagen Passat?A:The steering linkage and suspension parts must be maintained in a periodical, worn and damaged components may cause excessive tires, poor ride quality, handling and low fuel economy. To test the shock absorbers, one needs to park the car on a smooth surface, switch off the engine, and park the brake and then inspect the tire pressures. Press on one corner of the vehicle and release it, it should stop in one or two bounces and it will resume a level position but in case it does not stop or bounces back and forth, then the shock absorber will be worn. Do the same at the other corners then lift the vehicle safely on jackstands. Check the shock absorbers against water, and make sure that any water that is present is as a result of the shocks, and that the set should be replaced, in case of water leaks. Perform a check on secure mounting and damage and replace it as a set in case of any problems detected. To do the steering and suspension check, visually examine the components in terms of damage, distortion, and leakages, especially in seals, boots, and bushings. Wipe the bottom of the steering knuckle and have one person push the tire in and out and make sure there is no movement at the balljoint, any movement means it must be replaced. Check play in the steering system components by grabbing each front tire, and having a look at gear mounts and tie-rod ends to see whether they are loose or not. Driveaxle boots play a very important role in ensuring that dirt and water do not affect the CV joints hence they should be washed using soaps and water to avoid early wearing. Check the boots often on the presence of tears, cracks, and loose clamps and replace them in case of any concerns.

Related Volkswagen Passat Parts

Browse by Year

2022 CV Joint Boot 2021 CV Joint Boot 2020 CV Joint Boot 2019 CV Joint Boot 2018 CV Joint Boot 2017 CV Joint Boot 2016 CV Joint Boot 2015 CV Joint Boot 2014 CV Joint Boot 2013 CV Joint Boot 2012 CV Joint Boot 2010 CV Joint Boot 2009 CV Joint Boot 2008 CV Joint Boot 2007 CV Joint Boot 2006 CV Joint Boot 2005 CV Joint Boot 2004 CV Joint Boot 2003 CV Joint Boot 2002 CV Joint Boot 2001 CV Joint Boot 2000 CV Joint Boot 1999 CV Joint Boot 1998 CV Joint Boot 1997 CV Joint Boot 1996 CV Joint Boot 1995 CV Joint Boot 1994 CV Joint Boot 1993 CV Joint Boot 1992 CV Joint Boot 1991 CV Joint Boot 1990 CV Joint Boot