×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

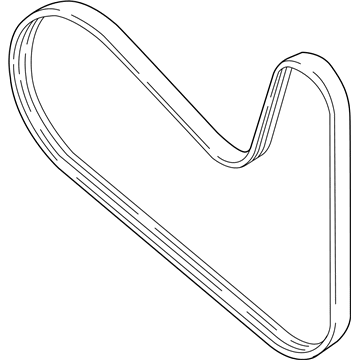

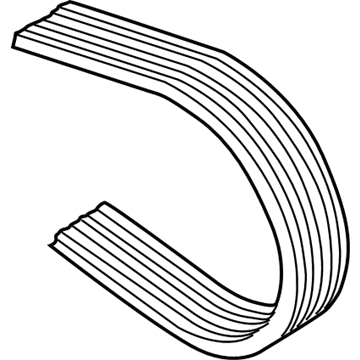

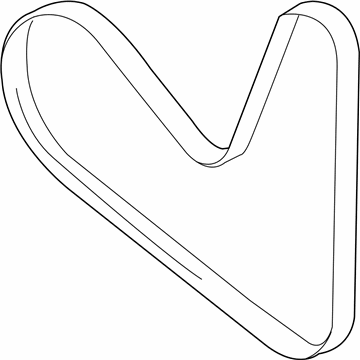

Genuine Volkswagen Passat Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

30 Drive Belts found

Volkswagen Passat Belt Part Number: 357-119-137

$8.24 MSRP: $13.50You Save: $5.26 (39%)Volkswagen Passat Alternator Belt Part Number: 027-903-137

$10.07 MSRP: $16.50You Save: $6.43 (39%)Volkswagen Passat Belt Part Number: 06B-903-137-E

$25.70 MSRP: $35.70You Save: $10.00 (29%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 07K-145-933-G

$26.51 MSRP: $36.82You Save: $10.31 (28%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 06F-260-849-L

$28.67 MSRP: $39.82You Save: $11.15 (28%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 03L-903-137-T

$29.51 MSRP: $40.99You Save: $11.48 (29%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 038-903-137-T

$29.99 MSRP: $41.65You Save: $11.66 (28%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 022-145-933-AP

$41.39 MSRP: $57.49You Save: $16.10 (28%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 037-260-849-C

$44.39 MSRP: $61.66You Save: $17.27 (29%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 037-903-137-G

$44.39 MSRP: $61.66You Save: $17.27 (29%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 04L-260-849-AB

$48.71 MSRP: $67.65You Save: $18.94 (28%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 021-145-933-C

$49.20 MSRP: $68.33You Save: $19.13 (28%)Ships in 1-2 Business DaysVolkswagen Passat Belt Part Number: 078-903-137-BC

$55.91 MSRP: $77.65You Save: $21.74 (28%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 07K-145-933-F

$77.34 MSRP: $108.31You Save: $30.97 (29%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 021-145-933-H

$101.96 MSRP: $142.80You Save: $40.84 (29%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 07D-145-933-E

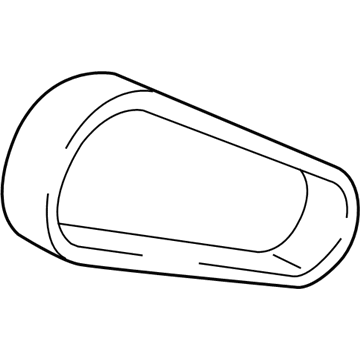

$140.55 MSRP: $196.84You Save: $56.29 (29%)Ships in 1-2 Business DaysVolkswagen Passat Pulley Part Number: 049-903-119-L

$203.92 MSRP: $285.60You Save: $81.68 (29%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 037-903-137-H

$28.32 MSRP: $39.33You Save: $11.01 (28%)Ships in 1-2 Business DaysVolkswagen Passat Serpentine Belt Part Number: 06K-260-849-A

$28.79 MSRP: $39.98You Save: $11.19 (28%)Ships in 1-2 Business DaysVolkswagen Passat Belt Part Number: 06K-121-605-C

$31.31 MSRP: $43.48You Save: $12.17 (28%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 30 Results

Volkswagen Passat Drive Belt

Choose OEM Drive Belt for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Drive Belt on your Passat, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Passat parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Passat Drive Belt Parts and Q&A

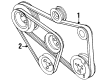

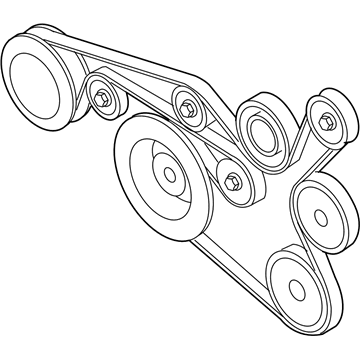

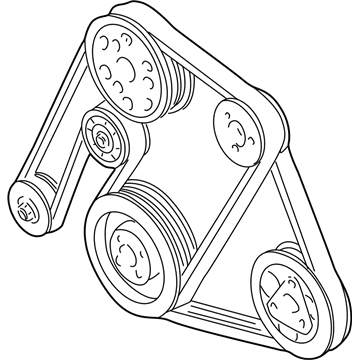

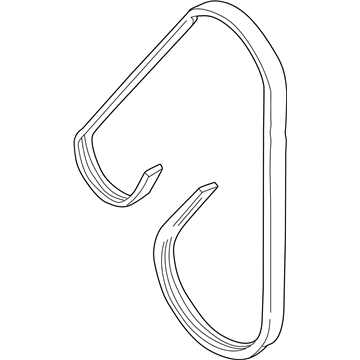

- Q: What role does the serpentine drive belt play in engine operation, and how should it be inspected and replaced on Volkswagen Passat?A:An engine component that is both vital to the engine and its parts as well as prone to wear is a serpentine and ribbed drivebelt that is at the front of the engine and which can only undergo some wear with time, thus requiring regular checks. In V6 engines, the drivebelt drives the cooling fan, alternator, power steering pump, water pump and air conditioning compressor, and in 1.8L four-cylinder engines there is one ribbed belt that drives the cooling fan, alternator and power steering pump and the other drives the air conditioning compressor, with a V-belt driven by the power steering pump pulley as on the water pump. To examine the belt, make sure that the engine is switched off and the hood is uncovered, observe cracks, separation, fraying, and glazing on both sides by twisting the belt. The under side ribs are to be even in depth. In V6-equipped engine, the ribbed drivebelt is kept at tension by a spring-loaded tensioner assembly, and in four-cylinder engines, a cooling fan, alternator and power steering pump belt is kept at tension by a spring-loaded adjuster, the air conditioning compressor belt may need some adjustment occasionally. To replace, in case the belt is to be used again then mark the direction of rotation. In the V6, align the engine cover, position the tensioner in order to relieve tension, unscrew the belt to the tensioner and its parts and re-fit the new belt back over top of the pulleys and restore engine cover. In four-cylinder models, lift the vehicle and take off the splash shield, tightenup tensioner bolts, and take off the air conditioning drivebelt, be sure that it is correctly seated in during installation and tensioned so it will deflect about 3/16-inch on a 25-pound force. In the case of the V-belt, the radiator support panel should be positioned in the service position, the serpentine drivebelt, engine cooling fan, and fan clutch assembly removed, the water pump pulley bolts unscrewed and the V-belt removed, and then reversed on the other side during installation making sure to position the water pump correctly. To change a tensioner that does not provide a correct tension or tie in, loosen the mounting bolts and reattach using the same procedure; however, tighten the bolts to the correct torque.

Related Volkswagen Passat Parts

Browse by Year

2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt 1996 Drive Belt 1995 Drive Belt 1994 Drive Belt 1993 Drive Belt 1992 Drive Belt 1991 Drive Belt 1990 Drive Belt