×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Rabbit Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Axle Shafts found

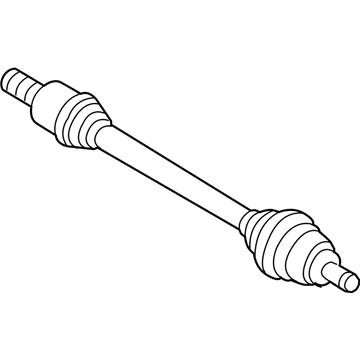

Volkswagen Rabbit Shaft Part Number: 171-498-099

$133.52 MSRP: $187.00You Save: $53.48 (29%)Volkswagen Rabbit Axle Part Number: 191-407-272-AQ

$549.00 MSRP: $750.00You Save: $201.00 (27%)Volkswagen Rabbit Axle Shaft Assembly Part Number: 171-407-272-NX

$254.76 MSRP: $342.30You Save: $87.54 (26%)Volkswagen Rabbit Axle Assembly Part Number: 1K0-407-271-BP

$165.65 MSRP: $198.86You Save: $33.21 (17%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 1K0-501-204-FX

$288.70 MSRP: $338.06You Save: $49.36 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 1K0-407-272-EB

$322.57 MSRP: $377.71You Save: $55.14 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 5Q6-407-272-R

$445.13 MSRP: $521.23You Save: $76.10 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 1K0-407-271-HN

$477.15 MSRP: $558.74You Save: $81.59 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 5Q0-407-271-DF

$502.77 MSRP: $588.74You Save: $85.97 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 5Q0-407-272-EF

$502.77 MSRP: $588.74You Save: $85.97 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 5Q0-407-272-FF

$502.77 MSRP: $588.74You Save: $85.97 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 1K0-407-271-LB

$521.99 MSRP: $611.23You Save: $89.24 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 1K0-501-203-F

$662.90 MSRP: $776.23You Save: $113.33 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 1K0-501-204-F

$662.90 MSRP: $776.23You Save: $113.33 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit CV Joints Part Number: 191-407-272-AS

$258.71 MSRP: $299.00You Save: $40.29 (14%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Assembly Part Number: 191-407-274-DX

$269.85 MSRP: $315.71You Save: $45.86 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Axle Part Number: JZW-407-449-X

$160.11 MSRP: $224.25You Save: $64.14 (29%)Ships in 1-2 Business Days

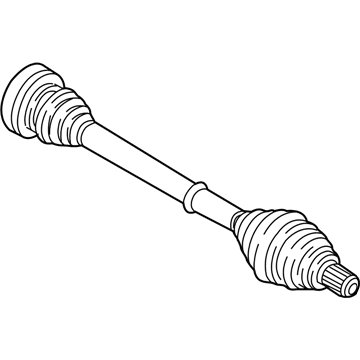

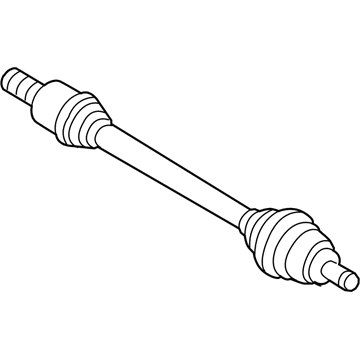

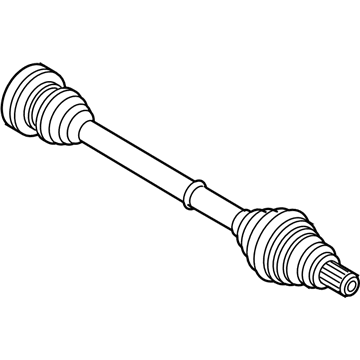

Volkswagen Rabbit Axle Shaft

Choose OEM Axle Shaft for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Axle Shaft on your Rabbit, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Rabbit parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Rabbit Axle Shaft Parts and Q&A

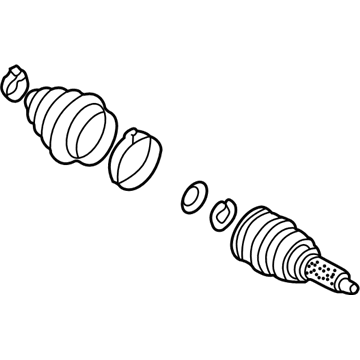

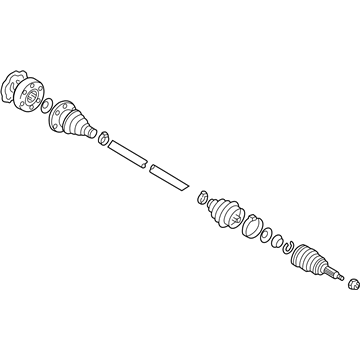

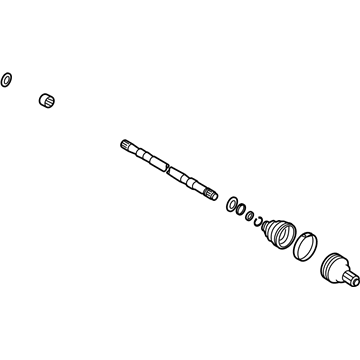

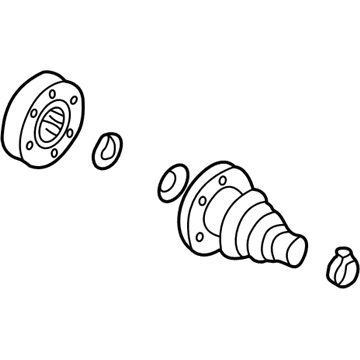

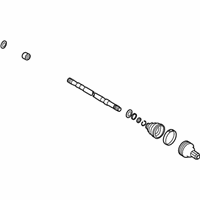

- Q: What role does the Axle Shaft play in transmitting power from the transaxle to the front wheels, and what are the key components and maintenance considerations involved on Volkswagen Rabbit?A:The transaxle also transmits power to the front wheels by use of two driveaxles, the inner end of which is either bolted to a drive flange by the differential or splined to the differential by the transaxle; the outer end of the driveaxle is a stub shaft splined to the hub and bearing assembly and held in place by a large bolt. The driveaxle has at its inner ends sliding constant velocity (CV) joints enabling both angular and axial movement and are made of either triple rotor-type bearing or ball-and-cage type bearing in a housing that allows it to slide with the wheel. The outer extremes are designed with the ball and cage type CV Joints that have angular movement that has no axial motion, consisting of 6 ball bearings between the inner race and the outer cage. The inspection of the boots should be done on a regular basis to determine whether it is damaged and the presence of lubricants and it should be noted that torn CV joint boots should be replaced at once so as to avoid the damage of the joints, the damaged boot should be removed and the driveaxle should be replaced. When the boots become damaged, the CV joint can be pulled apart and cleaned, although any damaged components might require the replacement of the whole driveaxle assembly, of which your local auto parts store can provide guidance on the type of component and the CV joint. Other typical signs of lost or damaged CV joints include the presence of lubricant leaks, clicking during turns, clunking after coasting, and vibrations at speeds of 60mph; to check weariness, hold one end of an axle and turn it in holding the CV joint housings, feeling any play indicating worn splines or loose joints and checking the driveaxle shafts, cracks, dents, and deformities.

- Q: How to remove and install an axle shaft on Volkswagen Rabbit?A:To disassemble the driveaxle, begin by removing the wheel trim or hub cap (where present) then a quarter turn of the driveaxle or hub bolt with the vehicle on its wheels and the loosening of the wheel bolts. Lift the front part of the vehicle and place it safely on jackstands, making sure that it does not roll over by blocking the rear wheels and then taking off the wheel. In the driveaxle models VL90, VL100, VL107, and AAR3300i, the bolts holding the inner CV Joint onto the transaxle drive flange (half shaft) are unscrewed, and the retaining plates are removed, taking care not to drop the driveaxle to avoid damaging it (clamped with a strap). In the case of the AAR2600i, lay a drain pan beneath the CV joint, force the inner CV joint ajar and do not destroy the seal of the differential, the transmission fluid will be emptied. Partially push the ABS wheel speed sensor out of its mounting hole in avoiding damage during withdrawal of the driveaxle and remove the driveaxle/hub bolt. This is followed by the removal of the balljoint mounting nuts, then the steering knuckle and the balljoint of the control arm are separated, which has a front level control sensor arm attached. When the outer joint is stuck in the hub, tap it with a brass drift or a puller when needed, and then swing the steering knuckle out to remove the driveaxle outer constant velocity joint out of the hub. Position the driveaxle so as to be out of the bottom of the vehicle, and dispose of the gasket of the inside constant velocity joint where present and also do not leave the vehicle on the wheels with the driveaxle out to avoid damage to the wheel bearings. To install, the transaxle drive flange and inside joint mating surfaces should be clean and dry, lubricate the outer joint and hub splines and then position the driveaxle, engaging the outer joint with the hub and fitting a new bolt without tightening all the way. Install the steering knuckle and balljoint to the control arm by screwing the balljoint nuts to the correct torque and then align the inner joint with the transaxle flange by fitting the retaining bolts and plates. In the case of the AAR2600i, a new spring clip to the inner end of the driveaxle is necessary, along with lubricating the seal and pulling the driveaxle into place and supporting the CV joints, making sure that the spring clip is inserted in its groove. Take grease on the spline of the outer CV joint, fit the stub axle into the hub, and screw the balljoint nuts in. Lastly, position the outer joint into place, place the wheel in place, lower the vehicle and finish installation by tightening the driveaxle/hub bolt and wheel bolts to desired torque and reconnecting the wheel trim or wheel hub cap, and refill the transmission fluid (where it might have been removed).