×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Rabbit Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Drive Belts found

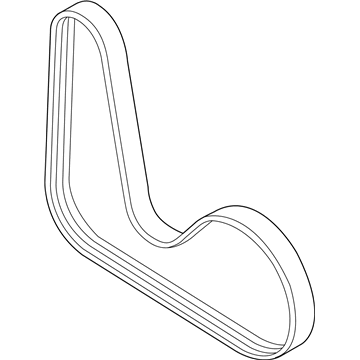

Volkswagen Rabbit Serpentine Belt Part Number: 06J-260-849-D

$32.27 MSRP: $44.81You Save: $12.54 (28%)Ships in 1-2 Business DaysVolkswagen Rabbit Serpentine Belt Part Number: 07K-145-933-C

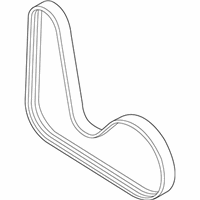

$30.71 MSRP: $42.65You Save: $11.94 (28%)Ships in 1-2 Business DaysVolkswagen Rabbit Belt Part Number: 055-903-137-G

$12.81 MSRP: $17.50You Save: $4.69 (27%)Ships in 1-2 Business DaysVolkswagen Rabbit Alternator Belt Part Number: 068-121-039-B

$13.66 MSRP: $18.67You Save: $5.01 (27%)Ships in 1-2 Business DaysVolkswagen Rabbit A/C Belt Part Number: 068-260-849

$18.54 MSRP: $25.33You Save: $6.79 (27%)Ships in 1-2 Business DaysVolkswagen Rabbit A/C Belt Part Number: 055-260-849-B

$21.26 MSRP: $29.05You Save: $7.79 (27%)

Volkswagen Rabbit Drive Belt

Choose OEM Drive Belt for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Drive Belt on your Rabbit, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Rabbit parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Rabbit Drive Belt Parts and Q&A

- Q: What is the role of drive belts in vehicle operation and how should they be inspected and replaced on Volkswagen Rabbit?A:The drivebelt(s) is/are found in front of the engine and has a significant role to play in the way the vehicle functions and its parts. The drivebelts are likely to fail with time as a result of their operation, and the material composition and thus should be checked and adjusted after some time to avoid serious engine damage. Four-cylinder models are furnished with one self-adjusting serpentine drivebelt, which provides motion to all parts of the accessory and five-cylinder models have two serpentine drivebelts in different applications. Checking, engine off, find the drivebelt, inspect both sides, looking for cracks, separation, and fraying and glazing, and twist the belt to examine the underside. The underside ribs must be equally deep, and the tensioner makes the adjustment of the belt automatically. To replace the four-cylinder engine, apply tension to the tensioner of the timing belt-equipped engine clockwisely, and loosen the timing belt by taking it out of the other auxiliary parts. Pass the new belt over the pulleys and make sure that it fits correctly. With five-cylinder engines, take out the front driver side part of the inner fender liner, and then clockwise turn the tensioner to position it in place as you change the air conditioning compressor outer belt and the alternator and water pump inner belt making sure they fit well in the pulley grooves. Replacing tensioners as a mechanic will mean that the drivebelt has to be removed after which the tensioner has to be removed and then installed, and it is the opposite of the removal process and proper torque on the mounting bolts has to be ensured.