×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Cabrio Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Discs found

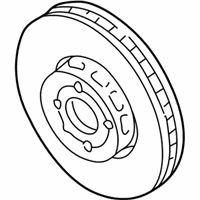

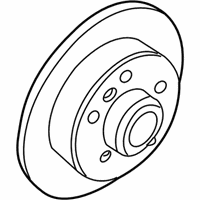

Volkswagen Cabrio Rotor Part Number: 6N0-615-601

$41.30 MSRP: $52.95You Save: $11.65 (22%)Volkswagen Cabrio Rotor Part Number: 6N0-615-301-D

$82.11 MSRP: $106.16You Save: $24.05 (23%)Ships in 1-2 Business DaysVolkswagen Cabrio Rotor Part Number: 2Q0-615-601-H

$59.64 MSRP: $77.11You Save: $17.47 (23%)Ships in 1-2 Business DaysVolkswagen Cabrio Rotor Part Number: 1HM-615-301-E

$53.78 MSRP: $68.95You Save: $15.17 (22%)

Volkswagen Cabrio Brake Disc

Choose OEM Brake Disc for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Brake Disc on your Cabrio, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Cabrio parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Cabrio Brake Disc Parts and Q&A

- Q: What steps should be followed to replace the brake disc and ensure proper installation on Volkswagen Cabrio?A:Both brake discs must be changed at the same time to provide even and equal braking and new braking pads ought to be fitted as well in case of either disc replacement. Loose the wheel lug bolts, block the front wheels, jack the rear of the car up, and firmly support it on jackstands, then remove the rear wheel. Check the disc, remove the two bolts that hold the bracket that clamps the brake caliper, and slide off the caliper and bracket assembly off the disc with a piece of wire, connecting the caliper and the coil spring of the rear suspension, so as not to strain the hydraulic Brake Hose. Tap and pry the top off the center of the brake disc with a hammer and a large flat-bladed screwdriver or chisel, and replace the top in case it is disfigured. Take out cotter pin of the hub nut, locking cap and remove the cotter pin because a new cotter pin is required during installation. The rear hub nut should be loosened and removed, the toothed washer slipped out and the outer bearing should be pushed out of the middle of the disc and the disc should slide over the stub axle. When a new disc is being installed, wipe of any preservative finish that may be on it with brake system cleaner, fit the bearing races, inner bearing and the oil seal where needed, and grease the outer bearing fully. Coat the hub bearing seal with grease and gently push the assembly onto the stub axle and then place the outer bearing and toothed thrust washer making sure that the tooth is properly in the axle slot. Installation Starting installation the hub nut should be tightened to a range of about 10 ft-lbs and the disc should be rotated until the bearings of the hub are in place, then turn the hub nut gradually to a loose state until the toothed washer can slide back and forth with little effort. Install a new cotter pin to position the hub nut, screw the cap to the center of the brake disc, and screw it into position completely. Insert the caliper into place over the disc with the pads exerting force over the disc and screw the caliper mounting bolts to the required torque. Lastly, put on the wheel, lower the vehicle to the ground and screw the wheel bolts to the recommended torque.

- Q: What does the inspection process for brake discs and pads involve on Volkswagen Cabrio?A:This is checking the brake discs and pads whether they are worn and damaged. In case either disc requires replacement, the other one must also be replaced at the same time to ensure uniform braking as well as replaceable brake pads. The first step would be to loosen the lug bolts of the front wheel, make sure that the parking brake is engaged, raise the front part of the car and then use jackstands to firmly hold it then remove the front wheel. Turn the brake disc round to check both sides; remove the brake pads, where needed. The normal light scoring is considered, whereas heavy scoring or cracks means that replacement is necessary. In case of light scoring, the disc may be resurfaced. Scraping off a rust lip around the perimeter of the disc is possible, although in some cases where there has been too much wear, the thickness of the disc can be measured at a number of points using a micrometer. In case the disc is less than the minimum thickness, then it should be machined or changed. The refinishing of both discs is necessary in case one is machined to keep constant thickness. Test with a dial indicator; excessive runout will have to be machined or replaced, but first a good hub bearing must be provided. Check the disc using a crack and other damages, and change it as applicable. To remove them, remove the brake pads on VW models and on Girling models, unscrew the bolts attaching the caliper mounting bracket and tie the caliper to prevent overloading the hydraulic hose. Indicate the position of the disc against the hub, unscrew the detaining screw and strip off the disc, tapping it lightly where needed. Installation is done in the opposite sequence as removal with making sure that the mating surfaces are clean, the marks are aligned, and the retaining screw is tightened. Should a new disc be installed, clean it then attach the caliper. In the case of Girling calipers, the caliper is mounted by placing it over the disc and screwing the mounting bolts. Lastly, fit the wheel, lower the vehicle and secure the wheel bolts and press the brake pedal till the regular pressure is restored.