×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Cabrio Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Oil Pump found

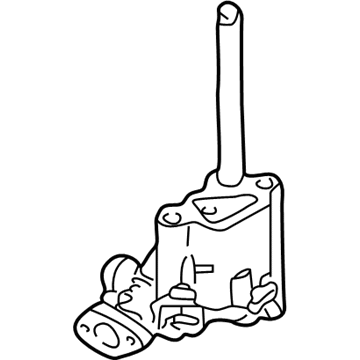

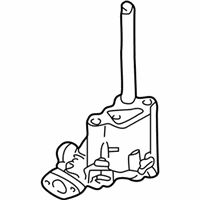

Volkswagen Cabrio Oil Pump Part Number: 027-115-105-B

$154.44 MSRP: $216.30You Save: $61.86 (29%)Ships in 1-2 Business Days

Volkswagen Cabrio Oil Pump

Choose OEM Oil Pump for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Oil Pump on your Cabrio, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Cabrio parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Cabrio Oil Pump Parts and Q&A

- Q: How to remove, inspect, and install the oil pump and pickup in the oil pan on Volkswagen Cabrio?A:The oil pump and pickup are attached to the Oil Pan and the drive is through the intermediate shaft which rotates half the crankshaft speed. The removal process involves disconnecting the oil pan to the crankcase, loosening or removing the bolts that hold the oil pump to the crankcase bottom and lifting both the oil pump and pickup out of the crankcase, retrieving the baffle plate where necessary. To inspect, take the screws of the mating flange to lift the pickup tube to retrieve the O-ring seal, then loosen and withdraw the screws to take out the oil pump cover. Clean the pump and check the gear teeth and see whether it is damaged or not. Measure pump backlash, with a feeler gauge placed between the teeth of the gears that are meshed, and rotate the gears just a bit to get the maximum clearance and compare with the stated limit. Measure axial clearance of pump; lay a straightedge in the oil pump casing and place a feeler gauge to determine the clearance between the straightedge and pump gears which is again compared with the limit. When either of the measurements is out of the recommended limit, then the pump will be worn out and it needs replacement. To install It has to install the oil pump cover then screws to the recommended torque then re-fit the oil pickup to the oil pump with a new O-ring seal and screws. Install the crankcase baffle plate (where needed) followed by installation of the oil pump to the crankcase, clamping it with mounting bolts, tightened to the required torque and lastly, the oil pan.