×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

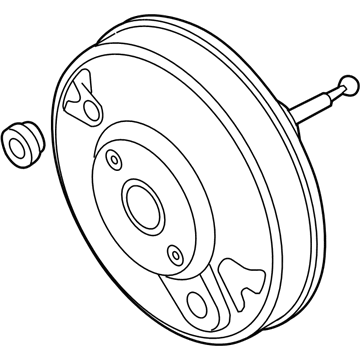

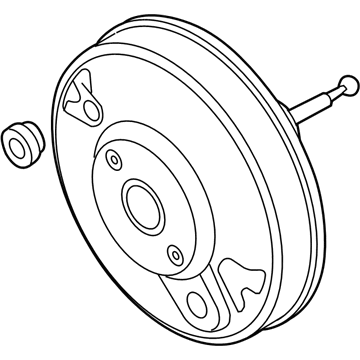

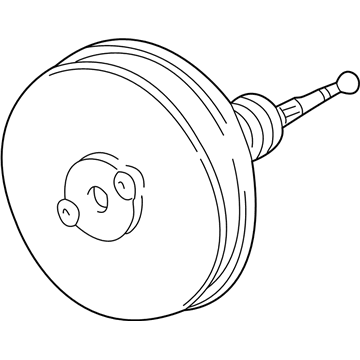

Genuine Volkswagen Passat Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Brake Boosters found

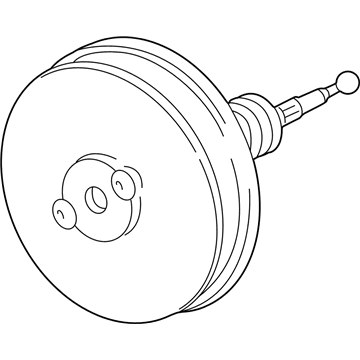

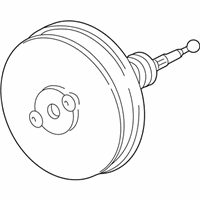

Volkswagen Passat Brake Booster Part Number: 8D0-612-107-B

$250.47 MSRP: $342.17You Save: $91.70 (27%)Volkswagen Passat Brake Booster Part Number: 3C1-614-106-P

$308.04 MSRP: $420.82You Save: $112.78 (27%)Ships in 1-2 Business DaysVolkswagen Passat Brake Booster Part Number: 3C1-614-106-Q

$317.19 MSRP: $433.32You Save: $116.13 (27%)Ships in 1-2 Business DaysVolkswagen Passat Brake Booster Part Number: 561-614-106-A

$144.36 MSRP: $202.18You Save: $57.82 (29%)Ships in 1-2 Business DaysVolkswagen Passat Brake Booster Part Number: 3C1-614-106-R

$335.49 MSRP: $458.32You Save: $122.83 (27%)Ships in 1-2 Business DaysVolkswagen Passat Brake Booster Part Number: 561-614-106-E

$350.74 MSRP: $479.15You Save: $128.41 (27%)Ships in 1-2 Business DaysVolkswagen Passat Brake Booster Part Number: 8E0-612-107-J

$408.69 MSRP: $558.32You Save: $149.63 (27%)Ships in 1-2 Business DaysVolkswagen Passat Brake Booster Part Number: 8E0-612-107-L

$408.69 MSRP: $558.32You Save: $149.63 (27%)Ships in 1-2 Business DaysVolkswagen Passat Power Booster Part Number: 4B3-612-107

$420.90 MSRP: $575.00You Save: $154.10 (27%)Ships in 1-2 Business DaysVolkswagen Passat Brake Booster Part Number: 3A1-612-107

$250.47 MSRP: $342.17You Save: $91.70 (27%)Volkswagen Passat Brake Booster Part Number: 357-612-107-A

$265.69 MSRP: $362.97You Save: $97.28 (27%)Volkswagen Passat Brake Booster Part Number: 3B0-612-107-D

$319.18 MSRP: $436.03You Save: $116.85 (27%)Ships in 1-2 Business DaysVolkswagen Passat Brake Booster Part Number: 3C1-614-106-M

$290.75 MSRP: $397.20You Save: $106.45 (27%)Ships in 1-2 Business DaysVolkswagen Passat Brake Booster Part Number: 3A0-698-107

$411.38 MSRP: $562.00You Save: $150.62 (27%)

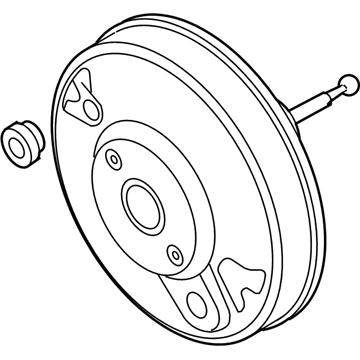

Volkswagen Passat Brake Booster

Choose OEM Brake Booster for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Brake Booster on your Passat, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Passat parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Passat Brake Booster Parts and Q&A

- Q: How to perform an operating check and remove or install a power brake booster on Volkswagen Passat?A:In order to do an operating check, press the brake pedal multiple times with the engine off to verify that no difference in the distance of the pedal reserve. Then switch the pedal and turn on the engine, in case the pedal sinks a little, everything is fine but in case it does not, look at the vacuum hose and the vacuum at the intake manifold with a vacuum gauge. To check air tightness, turn the engine on and to turn the engine off after one or two minutes, then depress the brake pedal slowly many times: as the pedal gets less and less in depressing, the booster is airtight. Also when running the engine press the brake pedal and turn off the engine keeping the pedal depressed and in case there is no change in the pedal travel after keeping the pedal in the hold position of 30 seconds, then the engine booster is airtight. To remove the power brake booster pushrod, one will need a special tool to unattach it to the brake pedal, and therefore one must make sure that the tool is available prior to the setup. In case not available, it can be built using materials that are easily available. To start with the master cylinder, take it off, then take off the vacuum hose connection very carefully by pulling out of the grommet in the booster. To dismantle the vehicle, unscrew the two bolts of the booster and reach behind the brake pedal with the special tool to detach the pushrod ball of the pedal then return to the engine compartment and remove the gasket on the rear. To install, ensure that the grommet sealing the vacuum hose is not damaged and change accordingly. Measure the distance between the booster mounting surface and the end of the pushrod ball head, it should be 6.26 +/- 0.020 inches, adjust the length of pushrod. Install a new gasket on the back of the booster unit, reinstall it on the firewall and tighten the mounting bolts. Install the booster pushrod and the brake pedal and make sure the pedal is firmly hooked, fit the brake light switch and the master cylinder. Then, placing the vacuum hose back into the booster, carefully, without knocking out the sealing grommet. Lastly, empty the brake hydraulic system, activate the engine to probe to a vacuum leak at the vacuum hose-to-booster grommet and ensure the functionality of the brake system in a secluded location before going back to the regular service.

Related Volkswagen Passat Parts

Browse by Year

2022 Brake Booster 2021 Brake Booster 2020 Brake Booster 2019 Brake Booster 2018 Brake Booster 2017 Brake Booster 2016 Brake Booster 2015 Brake Booster 2014 Brake Booster 2013 Brake Booster 2012 Brake Booster 2010 Brake Booster 2009 Brake Booster 2008 Brake Booster 2007 Brake Booster 2006 Brake Booster 2005 Brake Booster 2004 Brake Booster 2003 Brake Booster 2002 Brake Booster 2001 Brake Booster 2000 Brake Booster 1999 Brake Booster 1998 Brake Booster 1997 Brake Booster 1996 Brake Booster 1995 Brake Booster 1990 Brake Booster