×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Passat Coil Springs

Strut Spring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

57 Coil Springs found

Volkswagen Passat Spring Part Number: 561-411-105-B

$9.15 MSRP: $15.00You Save: $5.85 (39%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 561-411-105-A

$10.89 MSRP: $17.85You Save: $6.96 (39%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 561-511-115-A

$70.84 MSRP: $99.21You Save: $28.37 (29%)Ships in 1-2 Business DaysVolkswagen Passat Coil Spring Part Number: 561-411-105-C

$74.96 MSRP: $104.99You Save: $30.03 (29%)Ships in 1-2 Business DaysVolkswagen Passat Coil Spring Part Number: 561-411-105-E

$76.21 MSRP: $106.74You Save: $30.53 (29%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 561-411-105-D

$77.46 MSRP: $108.49You Save: $31.03 (29%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 561-511-115

$69.31 MSRP: $97.07You Save: $27.76 (29%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 161-411-105-F-951

$87.81 MSRP: $122.98You Save: $35.17 (29%)Volkswagen Passat Coil Spring Part Number: 561-511-115-B

$91.63 MSRP: $128.33You Save: $36.70 (29%)Ships in 1-2 Business DaysVolkswagen Passat Coil Spring Part Number: 561-511-115-F

$91.63 MSRP: $128.33You Save: $36.70 (29%)Ships in 1-2 Business DaysVolkswagen Passat Coil Spring Part Number: 357-411-105-D

$97.82 MSRP: $137.00You Save: $39.18 (29%)Volkswagen Passat Spring Part Number: 1K0-511-115-BG

$108.89 MSRP: $152.50You Save: $43.61 (29%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 1K0-511-115-BH

$108.89 MSRP: $152.50You Save: $43.61 (29%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 1K0-511-115-DE

$108.89 MSRP: $152.50You Save: $43.61 (29%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 357-411-105-R

$99.96 MSRP: $140.00You Save: $40.04 (29%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 1K0-511-115-BL

$111.51 MSRP: $156.17You Save: $44.66 (29%)Ships in 1-2 Business DaysVolkswagen Passat Spring Part Number: 1K0-511-115-DF

$111.51 MSRP: $156.17You Save: $44.66 (29%)Ships in 1-2 Business DaysVolkswagen Passat Coil Spring Part Number: 357-511-115-A

$102.10 MSRP: $143.00You Save: $40.90 (29%)Volkswagen Passat Spring Part Number: 3B0-511-115-AG

$108.29 MSRP: $151.67You Save: $43.38 (29%)Ships in 1-2 Business DaysVolkswagen Passat Coil Spring Part Number: 8D0-411-105-AQ

$113.05 MSRP: $158.33You Save: $45.28 (29%)Ships in 1-2 Business Days

| Page 1 of 3 |Next >

1-20 of 57 Results

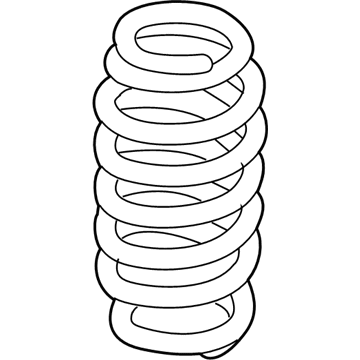

Volkswagen Passat Coil Springs

Choose OEM Coil Springs for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Coil Springs on your Passat, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Passat parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Passat Coil Springs Parts and Q&A

- Q: What should you do if the shock absorbers or coil springs show signs of wear on Volkswagen Passat?A:When the shock absorbers or coil springs may have been worn out (leaked fluid, damping ability, physically damaged, etc.), then investigate all the possibilities before beginning any work since the shock absorber cannot be serviced and it should be replaced in case of any issue. Shock absorber and coil spring assemblies can be purchased on exchange basis which will save time and effort and thus one can check the cost and availability of the parts and disassemble the vehicle. Start by taking out the shock absorber and spring assembly, putting it in a vise with wood or rags to ensure it is not damaged. To decongest the upper spring seat, install a spring compressor that you have followed the instructions of the manufacturer to make sure the spring is evenly compressed. Take out the nut of the shock absorber damper shaft without rotating the shaft, with an Allen wrench or a hex bit, and loosen the nut removal, after which the mounting plate, washer, upper spring seat, and upper spring support are removed. Then remove the dust boot, rubber bump stop and protective cap on the shock absorber piston, and remove the compressed coil spring with considerable care. Take away the lower spring support, and, when required, loosen the lower spring seat to the body of the shock absorber by means of a soft-faced mallet. Once the shock absorber is disassembled, check all parts of the shock absorber to check on its wear and tear replacing them where necessary. Confirm fluid leakage and check function of shock, move damper shaft full and short strokes, should be able to move without interruption; otherwise, change is necessary. In case of any suspicion regarding the status of the coil spring, then take out the spring compressor and check whether it is distorted or cracked and in that case replace it. Check the rest of the components and see whether they are damaged or deteriorated and replace only the suspicious ones. Place the bump stop and boot on the damper shaft and mount the coil spring on the shock absorber, making sure that the spring seat stop aligns well. Assemble upper spring support, spring seat, washer, and upper mounting and make sure that spring seat hole is positioned properly. Install a new damper shaft nut that does not allow spinning the shaft and screw it to the required torque. Lastly, gradually loosen the spring compressor and take it out being careful that the spring ends are in their correct position and the spring compressor and shock absorber assembly is then put back in place.

- Q: How to properly remove and install Coil Springs and Shock Absorber on the rear wheel and suspension components on Volkswagen Passat?A:Unscrew the bolts of the rear wheels and chock the front to stop the rolling of the vehicle. Lift the rear part of the car and place it firmly with jackstands in place and then remove the rear wheel. fix the brake caliper is removed, and supported by a piece of wire or string, but it must not hang on the hose. Disconnect the stabilizer bar link to the stabilizer bar and take away the nuts which fasten the stabilizer bar clamp. Unscrew the upper Control Arm-to-rear knuckle bolt, the shock absorber lower mounting bolt, and upper mounting bolts. To replace either the shock absorber/ coil spring assembly, pull down on the rear knuckle and direct the shock absorber/ coil spring assembly out. To install, just invert the uninstallation process but be sure to install new hardware. Tighten no suspension fasteners until the rear suspension has been raised to approximate normal ride height to avoid distortion of the bushing, and tighten all suspension fasteners to the recommended torque values. Install new brake calipers mounting bolts, screw them into place to a particular torque, assemble the wheel, tighten the mounting bolts, bring the vehicle down, and again tighten the mounting bolts.

Related Volkswagen Passat Parts

Browse by Year

2022 Coil Springs 2021 Coil Springs 2020 Coil Springs 2019 Coil Springs 2018 Coil Springs 2017 Coil Springs 2016 Coil Springs 2015 Coil Springs 2014 Coil Springs 2013 Coil Springs 2012 Coil Springs 2010 Coil Springs 2009 Coil Springs 2008 Coil Springs 2007 Coil Springs 2006 Coil Springs 2005 Coil Springs 2004 Coil Springs 2003 Coil Springs 2002 Coil Springs 2001 Coil Springs 2000 Coil Springs 1999 Coil Springs 1998 Coil Springs 1997 Coil Springs 1996 Coil Springs 1995 Coil Springs 1994 Coil Springs 1993 Coil Springs 1992 Coil Springs 1991 Coil Springs 1990 Coil Springs