×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Passat Driveshaft

Drive Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Driveshafts found

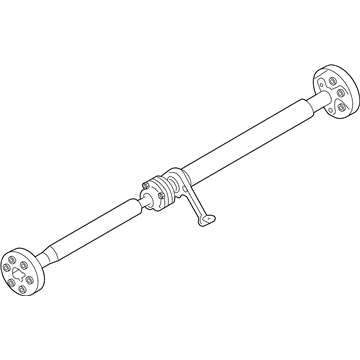

Volkswagen Passat Drive Shaft Part Number: 3C0-521-101-AJ

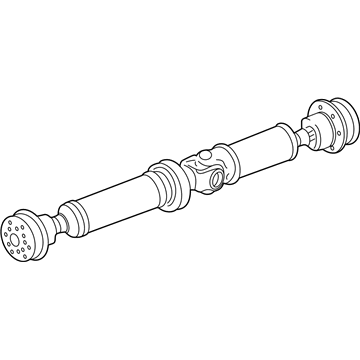

$1382.03 MSRP: $1618.29You Save: $236.26 (15%)Ships in 1-2 Business DaysVolkswagen Passat Drive Shaft Part Number: 3B0-521-101-R

$1268.80 MSRP: $1485.71You Save: $216.91 (15%)Ships in 1-2 Business Days

Volkswagen Passat Driveshaft

Choose OEM Driveshaft for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Driveshaft on your Passat, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Passat parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Passat Driveshaft Parts and Q&A

- Q: What precautions should be taken when handling the driveshaft, and what steps are involved in its removal and installation on Volkswagen Passat?A:It is important to remember that the driveshaft should not be bent at an angle steeper than 25 degrees and it is recommended that a holding device be used to hold both halves straight and this can be constructed of a piece of 2x4 of the correct size with wooden blocks at both ends. In case of the unavailability of a fixture, hold the driveshaft in a flat position with the help of a floor jack or otherwise. As of now, the drive shaft cannot be replacement parts so when the CV joints, U-joint, or center support bearing wear, the whole part will have to be replaced and it would be advisable to consult a professional in the field of drivelines to see what can be done to salvage the situation. The first thing to do is to elevate the vehicle and place it on jackstands and mark the position of the CV joints relative to the respective flanges. Hold up one end of the driveshaft and the other with support then loosen the bolts holding the CV joints in place. The next step is to take out the nuts connecting the center support bearing bracket to the floorpan with a note of the shim positions and remove the driveshaft carefully. To install them, follow the steps of removal in reverse though making sure that previous gasket material is removed and new gaskets are installed, new CV joint bolts are installed, heat shield must be restored to its original position, and shims should be returned to their original locations. Prior to attaching the center support bearing nuts, slide the bearing to the front and rear to indicate the position of the bracket on the floorpan then position the bracket in between the two indications and tighten all fasteners to the recommended values.