×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Passat Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

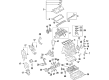

87 Engine Mounts found

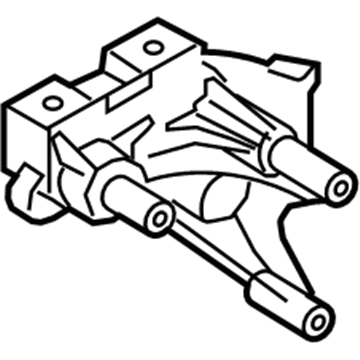

Volkswagen Passat Support Part Number: 1K0-199-588

$13.65 MSRP: $22.38You Save: $8.73 (40%)Ships in 1-2 Business DaysVolkswagen Passat Support Part Number: 1K0-199-588-A

$13.65 MSRP: $22.38You Save: $8.73 (40%)Ships in 1-2 Business DaysVolkswagen Passat Bushing Part Number: 1E0-199-233

$3.92 MSRP: $6.42You Save: $2.50 (39%)Ships in 1-2 Business DaysVolkswagen Passat Stop Part Number: 8D0-199-339-M

$15.90 MSRP: $26.05You Save: $10.15 (39%)Ships in 1-2 Business DaysVolkswagen Passat Stop Part Number: 8D0-199-339-L

$16.95 MSRP: $27.78You Save: $10.83 (39%)Ships in 1-2 Business DaysVolkswagen Passat Stop Part Number: 8D0-199-339-P

$16.95 MSRP: $27.78You Save: $10.83 (39%)Ships in 1-2 Business DaysVolkswagen Passat Support Part Number: 1K0-199-359-E

$38.66 MSRP: $53.71You Save: $15.05 (29%)Ships in 1-2 Business DaysVolkswagen Passat Stop Part Number: 8E0-199-335-M

$48.36 MSRP: $67.17You Save: $18.81 (28%)Ships in 1-2 Business DaysVolkswagen Passat Support Part Number: 3B7-199-343-C

$59.50 MSRP: $83.33You Save: $23.83 (29%)Ships in 1-2 Business DaysVolkswagen Passat Stop Part Number: 8D0-199-335-P

$63.25 MSRP: $88.58You Save: $25.33 (29%)Ships in 1-2 Business DaysVolkswagen Passat Stop Part Number: 8D0-199-335-F

$64.25 MSRP: $89.98You Save: $25.73 (29%)Ships in 1-2 Business DaysVolkswagen Passat Bushings Part Number: 1K0-199-867-Q

$72.46 MSRP: $101.49You Save: $29.03 (29%)Ships in 1-2 Business DaysVolkswagen Passat Bushings Part Number: 1K0-199-867-T

$72.46 MSRP: $101.49You Save: $29.03 (29%)Ships in 1-2 Business DaysVolkswagen Passat Bushings Part Number: 1K0-199-868-Q

$72.46 MSRP: $101.49You Save: $29.03 (29%)Ships in 1-2 Business DaysVolkswagen Passat Bushings Part Number: 1K0-199-868-T

$72.46 MSRP: $101.49You Save: $29.03 (29%)Ships in 1-2 Business DaysVolkswagen Passat Suspension Crossmember Mount Cushion Part Number: 8D0-399-415-D

$72.46 MSRP: $101.49You Save: $29.03 (29%)Ships in 1-2 Business DaysVolkswagen Passat Engine Cradle Front Bushing Part Number: 8D0-399-415-E

$72.46 MSRP: $101.49You Save: $29.03 (29%)Ships in 1-2 Business DaysVolkswagen Passat Mount Bracket Part Number: 535-199-354-C

$69.62 MSRP: $97.50You Save: $27.88 (29%)Volkswagen Passat Stop Part Number: 8D0-199-335-Q

$69.97 MSRP: $98.00You Save: $28.03 (29%)Ships in 1-2 Business DaysVolkswagen Passat Support Part Number: 06K-199-207-A

$75.43 MSRP: $105.66You Save: $30.23 (29%)Ships in 1-2 Business Days

| Page 1 of 5 |Next >

1-20 of 87 Results

Volkswagen Passat Engine Mount

Volkswagen Passat Engine Mount ensures that the engine is firmly mounted and that vibration is absorbed to provide drivers with a comfortable ride with no damage to parts caused by misalignment. The first Engine Mount available on this model was of the traditional rubber-and-steel type, with two brackets and an elastomer pad between them, which absorb noise as well as attach the motor to the subframe. As the car developed, some versions incorporated hydraulic mounts, which were fluid-filled chambers within the rubber that absorb a broader range of frequencies without allowing the engine to rock too much, a very important feature when accelerating hard. Later, top trims applied electronically controlled active Engine Mounts, which remain soft at idle to provide a smooth steering wheel feel but become stiffer as revs increase to restrain drivetrain geometry. The three styles have the same mission but different ways of integrating compliance and rigidity, with rubber mounts depending on the flexibility of the material, hydraulic units depending on liquid damping, and active mounts including sensors and control valves to make real-time changes. Aging rubber, heat, and exposure to oil may drain the fluid; hence, unusual shakes or clunks in a Passat should be investigated under the hood immediately before it becomes too late. Since the Volkswagen requires accurate alignment, an old Engine Mount may disrupt shifting and even fracture exhaust pipes; therefore, attention is critical to the health of the entire vehicle. The sturdy performance of every Volkswagen mount contributes to the feeling of confidence associated with the Volkswagen driving experience.

Choose OEM Engine Mount for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Engine Mount on your Passat, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Passat parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Passat Engine Mount Parts and Q&A

- Q: How should engine mounts be checked and replaced for V6 engines on Volkswagen Passat?A:Engine mounts do not usually need much maintenance, and failed or damaged mounts are replaced without delay to avoid any damage or wear on the parts of the drive line. In order to test the mounts, lift the engine slightly so that it is not on the mounts. Place the vehicle on jackstands, place a jack in between the engine Oil Pan and a large block of wood, and with caution, lift the engine slightly to avoid putting any weight on the mounts except where the drain plug is. Check the mounts with a large screwdriver or pry bar to verify that they are not cracked, hardened, and separated as well as verify that there is no relative movement between the mount plates and the engine or frame. When movement is observed reduce the engine and loosen the mounting fasteners, and rub on rubber preservative to prevent faster wear. To replace it, make sure that the car is firmly positioned in a way that engine is supported also. Take off the splash cover beneath the engine where it exists. When it comes to the front torque rod, the radiator support panel must be placed in the service position, remove the rubber stopper on the torque-rod, and replace it in case it is damaged. It is possible to remove the torque rod or to install a new one by simply unbolstering it in the front of the engine and install it back after doing the reverse. In the case of driver and passenger side engine mounts, park the car, put the parking brake on, block the rear tires and lift the front of the car safely on jackstands. Before unscrewing and removing the left and right engine mount nuts, remove the splash shield, if fitted, and defreeze the starter motor cables of the lower engine mount brackets, labeling the position of the engine mount locating dowel in relation to the aluminum engine mount bracket. Keel the front stabilizer bar with a floor jack, unscrew them and remove the engine mount bracket bolts in the appropriate sequence and then lower the aluminum engine mount brackets with the stabilizer bar to the ground. Detach the engine mount on the engine block bracket, and dissolve (where necessary) the mounting bracket on the side of the cylinder block, and installing is the opposite of the procedure.

Related Volkswagen Passat Parts

Browse by Year

2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2014 Engine Mount 2013 Engine Mount 2012 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount 2006 Engine Mount 2005 Engine Mount 2004 Engine Mount 2003 Engine Mount 2002 Engine Mount 2001 Engine Mount 2000 Engine Mount 1999 Engine Mount 1998 Engine Mount 1997 Engine Mount 1996 Engine Mount 1995 Engine Mount 1994 Engine Mount 1993 Engine Mount 1992 Engine Mount 1991 Engine Mount 1990 Engine Mount