×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Rabbit Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Camshafts found

Volkswagen Rabbit Camshaft Part Number: 049-109-101-J

$296.31 MSRP: $404.80You Save: $108.49 (27%)Volkswagen Rabbit Camshaft Part Number: 049-109-101-C

$300.46 MSRP: $410.47You Save: $110.01 (27%)Volkswagen Rabbit Camshaft Part Number: 07K-109-102-C

$375.14 MSRP: $512.49You Save: $137.35 (27%)Ships in 1-2 Business DaysVolkswagen Rabbit Camshaft Part Number: 07K-109-101-E

$384.29 MSRP: $524.99You Save: $140.70 (27%)Ships in 1-2 Business DaysVolkswagen Rabbit Camshaft Part Number: 068-109-101-B

$418.98 MSRP: $572.38You Save: $153.40 (27%)

Volkswagen Rabbit Camshaft

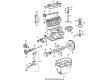

Choose OEM Camshaft for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Camshaft on your Rabbit, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Rabbit parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Rabbit Camshaft Parts and Q&A

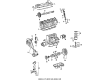

- Q: What precautions should be taken when disconnecting the battery and performing camshaft and rocker arm repairs for Four-cylinder engines on Volkswagen Rabbit?A:When it happens that the battery is disconnected, there are a number of systems which need to be relearned before they become functional. There will be severe engine damage in case of mistakes; one should not do this work unless he or she is very experienced in such kind of work. In case of doubt, seek professional advice and recheck all the work to assure that it is all right and only then you can start up the engine. Before installation, the camshafts and lifters must be carefully examined and the endplay of camshaft measured before removal. Even though hydraulic lifters are self-adjusting and do not need any periodical maintenance, in-vehicle check of overly noisy hydraulic lifters is done. With Timing Belt (BPY) engines, un screw the negative battery cable, take off the engine cover and high-pressure fuel pump, the Valve Cover and coolant tube, un screw the camshaft adjustment valve and the vacuum pump, then take off the battery and tray, and then start to work on camshaft removal. In Timing Chain (CCTA, CBFA) engines, the negative battery cable should be disconnected, the vehicle raised, the lower splash shield, engine cover, ignition coils, and spark plugs removed and the engine turned to TDC, then many parts are removed, such as the air charge pipe and the vacuum pump. During inspection, camshaft bearing surfaces are investigated on the damage, oil clearance dimension, and the journal and bearing dimensions of the camshaft runout is also examined, rocker arm rollers and lash adjusters also are investigated on whether they are worn. To install, lubricate and clean camshafts and bearing surfaces then re-fit in normal positions, lubricate the guide frame with sealer and make sure that timing components are well aligned. Once it is installed, do not turn the crankshaft within 30 minutes, but then very carefully rotate it by hand, at least two full revolutions, feeling some resistance and aligning TDC marks.

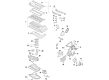

- Q: What precautions should be taken when disconnecting the battery and inspecting the camshaft and rocker arm for Five-cylinder engines on Volkswagen Rabbit?A:Disconnection of the battery is discouraged because after properly re-learning a number of systems, it fails to work as expected, and any error may result in serious engine damage. Such a procedure should be undertaken by people with great experience and they should seek the advice of an expert where there is any doubt of ability. It is important to make sure that one verifies all the work to be sure before engaging the engine. The camshafts and lifters should be properly inspected before being installed with the endplay of camshafts examined before being removed. Disassemble by first locking in the timing adjustment position of the camshafts, then remove the camshaft sprocket and Timing Chain and make sure lobes and slots align when re-installed. The bolts of the camshaft guide frame, which is made up of all caps in a single assembly, must be slowly loosened to equalize the pressure of the valve springs. Install new guide bolts because the old type of fasteners, stretch type, will not yield accurate torque readings. Once the guide frame and camshafts have been removed, remove all gasket sealing material off of both mating surfaces and never reassemble the piece of equipment unless it passes a comprehensive inspection. Physically inspect camshaft bearing surfaces to eliminate any damage; any scoring found on the surfaces of the cylinder head and guide frame requires replacement. Measure the best-diameter of each journal of the camshaft bearing and the inside diameter of the corresponding bearers, which may require noting that excessive wear may require new parts. In order to measure the camshaft runout, re-fit the camshaft into the cylinder head and connect a dial indicator to the center journal and record the readings with reference to the set values. To determine the camshaft endplay, a dial indicator is temporarily attached to the cylinder head cover or guide frame and then the movement of the guide frame is measured. Excessive guide frame wear should be noted. Check the heights of the cam lobes using the micrometer and it should be checked only between intake lobes to intake lobes and the exhaust lobes to the exhaust lobes and when the difference between them is more than 0.005 inch it is time to replace them. Check the lash adjusters and rocker arm rollers wear, avoid setting the adjusters on their side, or upside down to avoid trapping air, and make sure that all lash adjusters slide freely in their bores to avoid any possible internal engine damage.