×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Rabbit Cam Gear

Camshaft Gear- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Cam Gears found

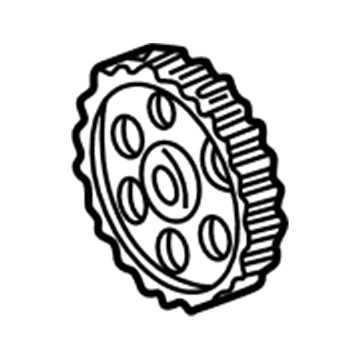

Volkswagen Rabbit Camshaft Gear Part Number: 069-109-111

$130.89 MSRP: $183.32You Save: $52.43 (29%)Ships in 1-2 Business DaysVolkswagen Rabbit Camshaft Gear Part Number: 07K-109-571-D

$65.44 MSRP: $91.66You Save: $26.22 (29%)Ships in 1-2 Business DaysVolkswagen Rabbit Actuator Part Number: 07K-109-083-F

$292.79 MSRP: $399.98You Save: $107.19 (27%)Ships in 1-2 Business Days

Volkswagen Rabbit Cam Gear

Choose OEM Cam Gear for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Cam Gear on your Rabbit, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Rabbit parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Rabbit Cam Gear Parts and Q&A

- Q: What precautions should be taken with the Cam Gear and Timing Belt during the replacement procedure to avoid engine damage on Volkswagen Rabbit?A:This process should be done with caution because rotating the crankshaft or the Camshaft individually with the timing belt off, can result in damages to the valves; however a slight rotation of the camshaft is only allowed so as to align the sprocket marks. In case of battery disconnection, a number of systems will need to be re-learned to work accordingly. The timing system is difficult, and it may cause serious damages to the engine in case of errors, and hence this procedure should be undertaken by only experienced persons. Start by unhooking the negative battery cable, loosening the right front wheel bolts, lifting the vehicle and dismounting the right front wheel. The second step is to take out the lower splash shield, disconnection of the fuel pump electrical connector, and the engine cover. Shut down and de-couple the fuel lines, empty a bit of coolant and de-couple the coolant pipe. Take off the coolant reservoir, inner fender liner on the driver side and the charge air cooler lower connector pipe. Record the direction of rotation of the drive belt, take it out together with the spark plugs and relieve the tensioner. When it comes to particular production models, take out the timing belt inspection cover, or upper cover fasteners. Turn the engine to TDC of cylinder No. 1, with the mark on the camshaft sprocker in the rear corresponding with that of the timing belt. Turn off crankshaft rotation when removing pulley retaining bolts with an offset box wrench and ensure that the crankshaft is not turned out of TDC. Loosen the lower timing belt cover that has the fasteners, place the engine, and take away the air conditioning line bracket clamps without the lines. Continue by taking out the front exhaust pipe, the drive axles, the pendulum mount and front Engine Mount. Once all the timing belt cover fasteners are removed, loosen the tensioner pulley nut and then rotate the tensioner in a counterclockwise direction to take off the timing belt. Check tensioner pulley and idler wheel work well and inspect the belt to confirm that there is no contamination or damage on the belt. Where there is doubt of the belt, change the belt, which is particularly the case when the belt has travelled over 60,000 miles. When engaging the engine, turn the crankshaft by hand two full rotations to confirm that there is no resistance, and it may be an indication of problems. Make sure that the crankshaft is at TDC, replace all parts that have been removed and loop the timing belt under the crankshaft sprocket and make sure it gets around the pulleys in the correct direction. Apply tension to the belt with the tensioner, fit the lower timing belt cover and crankshaft pulley, and rotate the crankshaft two full revolutions to check the alignment marks and then install the rest of the parts in the reverse order.