×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

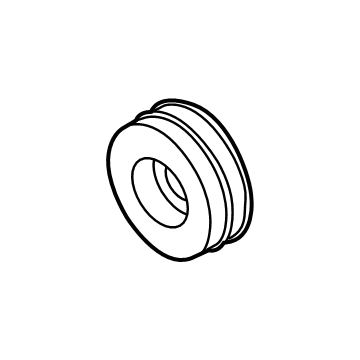

Genuine Volkswagen Rabbit Harmonic Balancer

Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Harmonic Balancers found

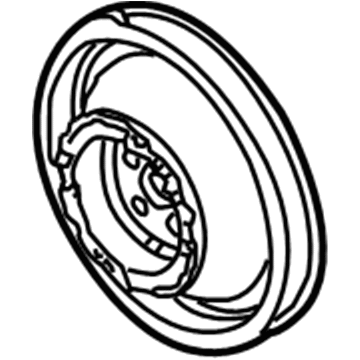

Volkswagen Rabbit Pulley Part Number: 06H-105-243-K

$198.72 MSRP: $278.31You Save: $79.59 (29%)Ships in 1-2 Business DaysVolkswagen Rabbit Pulley Part Number: 07K-105-243-F

$411.74 MSRP: $562.49You Save: $150.75 (27%)Ships in 1-2 Business DaysVolkswagen Rabbit Pulley Part Number: 068-105-243-A

$172.31 MSRP: $241.33You Save: $69.02 (29%)

Volkswagen Rabbit Harmonic Balancer

Choose OEM Harmonic Balancer for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Harmonic Balancer on your Rabbit, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Rabbit parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Rabbit Harmonic Balancer Parts and Q&A

- Q: How to remove and install the drivebelt while ensuring the harmonic balancer and crankshaft remain at TDC on Volkswagen Rabbit?A:In order to take off the drivebelt, do the following. When unscrewing the pulley bolts, the crankshaft should not be allowed to turn; a two-pin type spanner will be able to get into the hub and fix the crankshaft pulley. One should be cautious because the pry bar or other tools used may end up destroying the crankshaft pulley. Use the holding tool by inserting it into the spacing of the front face of the pulley to hold it in place and take out the crankshaft pulley retaining fasteners. This process is important to ensure that the crankshaft pulley is firmly held to prevent engine damage or valve timing shift in case the crankshaft leaves the TDC position. Once all the screws of the pulley bolts have been unscrewed, take the holding tool and pulley out. To install, apply a little clean engine oil on the crankshaft front seal then install the crankshaft pulley. When the seal appears to leak then change it before being installed. Install and hand tighten only new crankshaft pulley bolts. The next step involves the addition of the holding tool into pulley and tightening the crankshaft pulley bolts to the required torque. Lastly, disconnect the crankshaft holding tool and threaded crankshaft alignment bolt of the pulley and front engine cover, remove the locking pin of the cylinder block. The rest of the installation is the reverse of the de-installation.