×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Rabbit Rack and Pinions

Steering Rack- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Rack and Pinions found

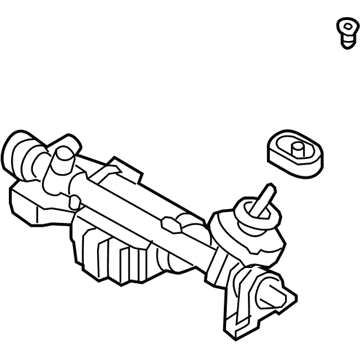

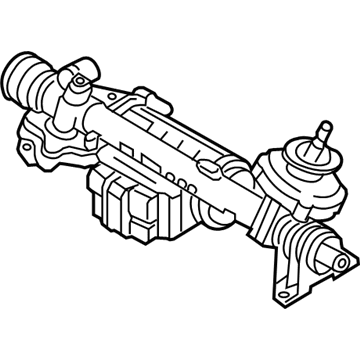

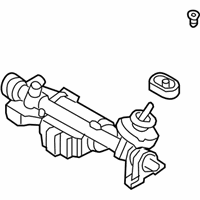

Volkswagen Rabbit Steering Gear Part Number: 1K1-423-055-FX

$787.16 MSRP: $988.00You Save: $200.84 (21%)Ships in 1-2 Business DaysVolkswagen Rabbit Steering Gear Part Number: 1K1-423-055-M

$2918.84 MSRP: $3417.84You Save: $499.00 (15%)Ships in 1-2 Business DaysVolkswagen Rabbit Steering Gear Part Number: 175-422-061-X

$565.23 MSRP: $765.00You Save: $199.77 (27%)Volkswagen Rabbit Steering Gear Part Number: 171-419-063

$753.35 MSRP: $950.00You Save: $196.65 (21%)

Volkswagen Rabbit Rack and Pinions

Choose OEM Rack and Pinions for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Rack and Pinions on your Rabbit, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Rabbit parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Rabbit Rack and Pinions Parts and Q&A

- Q: What precautions should be taken when disconnecting the battery and replacing the steering gear on Rack and Pinions on Volkswagen Rabbit?A:When disconnecting the battery a number of systems will have to be re-learned to enable them work well again. The steering gear cannot be repaired, in case it is worn or damaged, it will have to be replaced. The first step would be to park the vehicle so that the front wheels are facing straight ahead with the parking brake on and the back wheel chocked and then the front wheel bolts are loosened. Jackknifing the front part of the vehicle and resting it on jackstands, then loosen the two front wheels. Then take out the battery in the engine compartment. Turn the steering wheel to the center position and take out the ignition key to turn on the steering lock, make sure that the Steering Column is straight during the whole process to avoid the mispositioning of the airbag contact unit. Disassemble the panel on the driver side under dashboard and fasten the lower part of the steering column to the upper part but without disconnecting them to the steering gear. Unscrew the footwell cover and its cover and the pinch bolt that holds the universal joint in place on the input shaft of the steering gear. Installation Remove steering column universal joint off the steering gear input shaft and position aside, and then (when equipped) remove the input shaft cover out of the firewall into the vehicle. In models which have hydraulic power steering, drain the fluid in the power steering fluid reservoir or empty it into a container in the event of hydraulic lines being disconnected. Install hose clamps on the fluid system in and out of the steering gear, but not to damage the hose. Take off the bottom splash shield under the engine, the heat shield fasteners and heat shield of the subframe (where equipped) and the exhaust system bracket fasteners of the subframe. Remove the stabilizer bar links, clamps on the stabilizer bar, the lower Control Arms off the balljoints, tie-rods off the Steering Knuckles and the clamps. Eliminate the steering gear-to-subframe fasteners. In models that have an electromechanical steering gear, have the subframe supported on a floor jack, and remove the bolts connecting the rear subframe, lowering it a bit, without overstraining any electrical wiring. To remove the steering gear heat shield, heat shield, and steering gear cable guide clips on the subframe, to remove electrical connector to the steering gear, and to unconnect the cable guide clips to the steering gear, etc. Gentle Carefully move the bottom of the subframe downward, making sure that steering gear is pulled off the subframe and out of the vehicle, without damaging any steering gear control module. The steering gear should then be mounted on the subframe and the electrical connectors are to be connected so that the holes in the steering gear are aligned with the holes in the subframe and then mount the steering gear and then tighten the mounting bolts to the required torque. The rest of the installation is a reversal of removal, which ensures to re-connect the subframe, tie-rod ends, tighten the wheel bolts to the required torque, and make the wheel alignment checked and adjusted as needed. In models that have the hydraulic steering gear, unscrew the fittings and disconnect the fluid feed and return lines with the steering gear, wiping the connections and then removing them. Wring out all the remaining fluid and pour it into a drinking vessel to be disposed of, and wrap the lines up again out of the work, and tie the ends together to stop leaks and the introduction of dirt. Lift the subframe with a floor jack, disconnect the rear subframe bolts and shift the rear downward just low enough to lift out the steering gear off the subframe and out of the vehicle without straining electrical wiring. Install the steering gear The steering gear includes the steering gear-to-subframe mounting bolts, which are to be tightened to the recommended torque. Install the steering gear onto the subframe, line up the mounting holes and install the steering gear-to-subframe mounting bolts. The rest of the installation involves a reversal of the removal as this will make sure that the pressure and return line fittings are connected to the steering gear, the pressure line tightened to the required torque, the tie-rod ends reconnected, the fluid levelled, the system bled, the wheel bolts tightened to the required torque and then get the wheel alignment checked and corrected as necessary.