×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

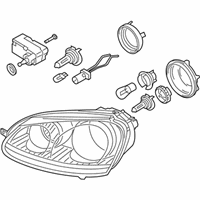

Genuine Volkswagen Rabbit Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Headlights found

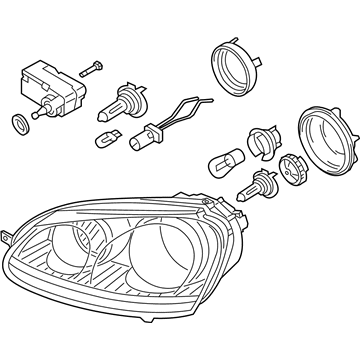

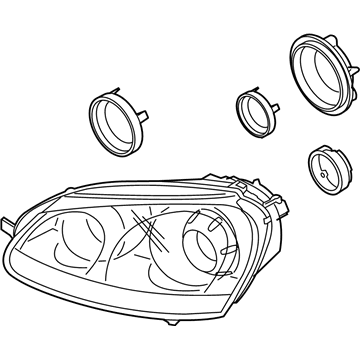

Volkswagen Rabbit Headlamp Assembly Part Number: 1K6-941-005-S

$215.89 MSRP: $302.37You Save: $86.48 (29%)Ships in 1-2 Business DaysVolkswagen Rabbit Headlamp Assembly Part Number: 1K6-941-006-S

$260.04 MSRP: $355.25You Save: $95.21 (27%)Ships in 1-2 Business DaysVolkswagen Rabbit Headlamp Assembly Part Number: 1K6-941-039-B

$410.65 MSRP: $561.00You Save: $150.35 (27%)Ships in 1-2 Business DaysVolkswagen Rabbit Headlamp Assembly Part Number: 1K6-941-040-B

$410.65 MSRP: $561.00You Save: $150.35 (27%)Ships in 1-2 Business Days

Volkswagen Rabbit Headlight

Choose OEM Headlight for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Headlight on your Rabbit, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Rabbit parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Rabbit Headlight Parts and Q&A

- Q: How to disconnect the electrical harness connector from the headlight housing and remove it on Volkswagen Rabbit?A:Unscrew the electrical harness connector of the headlight housing, but in 2010 models only it can be unscrewed after shifting the housing forward. Pull off the bumper cover and also put masking tape on the portions of the body around the headlight housing to avoid damages. The next step is to take off the upper fastener and lower fasteners then strip all the headlight housing out. Installation is the opposite of the uninstallation process and there must be adjustments done after installing the headlight housing.

- Q: How should headlights be adjusted, and what precautions should be taken during the process on Volkswagen Rabbit?A:Some models are equipped with a headlight leveling system, and the adjustment procedure does not apply to those models; therefore, have the headlights adjusted by a dealer service department or a qualified repair shop. Models with headlight housings feature three adjustment screws: one for left-and-right movement, one for up-and-down movement for both high and low beams, and a third for low beam up-and-down movement. The third screw is specifically for raising or lowering the low beam after the high beam has been adjusted. Several methods exist for adjusting the headlights, with the simplest requiring an open area with a blank wall and a level floor. Begin by positioning masking tape vertically on the wall in line with the vehicle centerline and the centerlines of both headlights, followed by a horizontal tape line aligned with the centerline of all headlights; it may be easier to place the tape with the vehicle parked just a few inches away. Adjustments should be made with the vehicle parked 25 feet from the wall, sitting level, with the gas tank half-full and no unusually heavy load. For high beam adjustment, position the high intensity zone two inches below the horizontal line and two inches to the side of the vertical headlight line, away from oncoming traffic, twisting the adjustment screws until the desired level is achieved. For low beam adjustment, repeat the process, ensuring the high intensity zone is also two inches below the horizontal line and two inches to the side of the vertical headlight line, away from oncoming traffic. With the high beams on, the high intensity zone should be vertically centered with the exact center just below the horizontal line. It is advisable to have the headlights adjusted by a dealer service department at the earliest opportunity.