×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

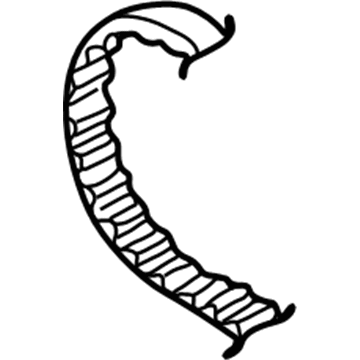

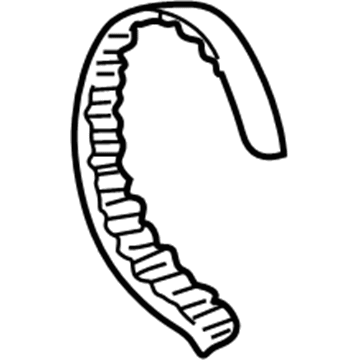

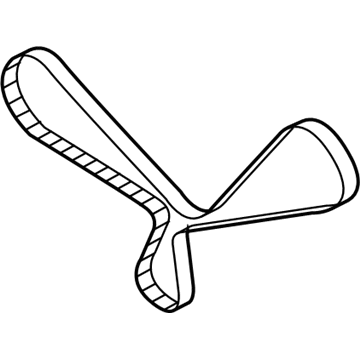

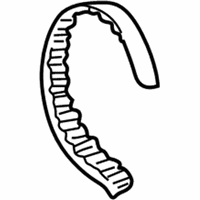

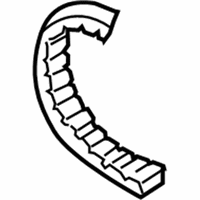

Genuine Volkswagen Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Timing Belts found

Volkswagen Timing Belt Part Number: 027-109-119-C

$46.51 MSRP: $64.60You Save: $18.09 (28%)Product Specifications- Other Name: Tooth Belt

- Replaces: 027-109-119-A

Volkswagen Timing Belt Part Number: 058-109-119-D

$49.32 MSRP: $68.50You Save: $19.18 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 074-109-119-F

$57.24 MSRP: $79.50You Save: $22.26 (28%)Product Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 06A-109-119-D

$8.34 MSRP: $11.40You Save: $3.06 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 068-109-119-E

$71.39 MSRP: $99.98You Save: $28.59 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 06B-109-119-F

$80.91 MSRP: $113.31You Save: $32.40 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 06B-109-119-A

$84.48 MSRP: $118.31You Save: $33.83 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 7B0-109-119

$87.91 MSRP: $123.12You Save: $35.21 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Ribbed Belt

Volkswagen Timing Belt Part Number: 058-109-119-C

$88.05 MSRP: $123.32You Save: $35.27 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 028-109-119-P

$95.19 MSRP: $133.32You Save: $38.13 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 038-109-119-M

$109.47 MSRP: $153.31You Save: $43.84 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

- Replaces: 038-109-119-D, 038-109-119-B

Volkswagen Timing Belt Part Number: 078-109-119-J

$121.37 MSRP: $169.99You Save: $48.62 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

- Replaces: 078-109-119-G, 078-109-119-H

Volkswagen Timing Belt Part Number: 038-109-119-P

$129.70 MSRP: $181.65You Save: $51.95 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 037-109-119-C

$59.39 MSRP: $82.48You Save: $23.09 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

- Replaces: 048-109-119-D

Volkswagen Timing Belt Part Number: 056-109-119-A

$63.06 MSRP: $88.33You Save: $25.27 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

Volkswagen Timing Belt Part Number: 03L-109-119-E

$153.50 MSRP: $214.98You Save: $61.48 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

- Replaces: 03L-109-119-G, 03L-109-119-C, 03L-109-119-J

Volkswagen Timing Belt Part Number: 03L-109-119-F

$159.45 MSRP: $223.32You Save: $63.87 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tooth Belt

- Replaces: 03L-109-119-D, 03L-109-119

Volkswagen Timing Belt Part Number: 04E-198-119-A

$278.60 MSRP: $380.61You Save: $102.01 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Repair Kit

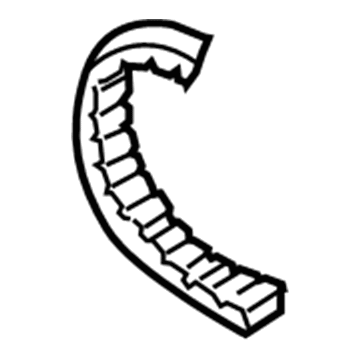

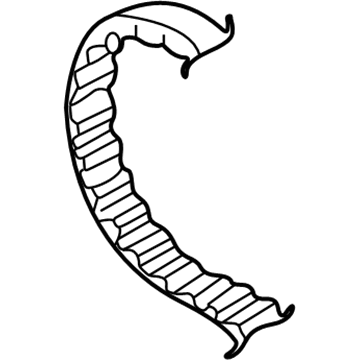

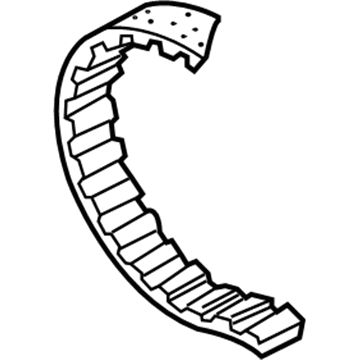

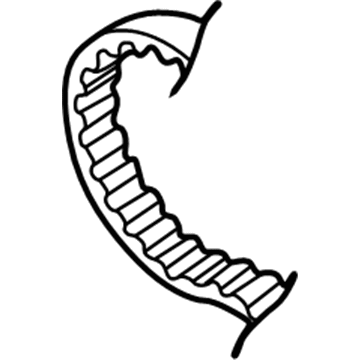

Volkswagen Timing Belt

The timing belt is a must-have if you want to make sure that the crankshafts and camshafts have their rotations timed accurately during engine operation. Without it, the engine would suffer major destruction due to misaligned gears and pistons. Commonly made from rubber reinforced with high-strength fibers, Volkswagen timing belts should be changed every sixty thousand miles for proper combustion of the engine.

OEM (Original Equipment Manufacturer) Volkswagen Timing Belts are perfect for motorists because they are the best quality parts produced as per the manufacturer's specifications; hence, they perform well and are reliable too, thus helping to retain the car's initial functionality as well as safety features. At VWPartsGiant.com, our genuine Volkswagen Timing Belt supply indicates how much we care about the health of your vehicle. Additionally, our stock is vast, so every product will be easily accessible to you for finding and swapping without fear of making mistakes. With our user-friendly online catalog, it takes no time to identify the right spare part. Therefore, convenience accompanies servicing or maintaining a motorcar. You can rely on our OEM Volkswagen Timing Belt to sustain the performance of your automobile.

Volkswagen Timing Belt Parts and Q&A

- Q: What are the steps involved in removing and installing a toothed timing belt for Gasoilne engines on Volkswagen Cabrio?A:The toothed timing belt is the one that mostly moves the camshafts and the intermediate shaft and in case it slips or breaks, it may alter the timing of the valves and the piston-to-valve contact may occur and result into severe damage to the engine. Thus, it is essential to make sure that tensioning is performed correctly and that wear or deterioration is checked on a regular basis. First, put the vehicle and engine into immobility by loosening the negative battery cable, setting on the parking brake, and chocking the rear wheels. Enhance the accessibility of the timing belt covers by eliminating the air cleaner housing ducting and crankcase breather hose. Lift the timing belt cover by pushing the metal spring clips open and the securing screws, then lifting the cover. Disassemble the V-belt and ribbed drive belt, align an engine with TDC on cylinder No. 1 with alignment markings and remove the retaining screws to take out the ribbed drive belt pulley. Disassemble the water pump pulley, the timing belt lower cover, and take the tension off the timing belt by loosening the tensioner mounting nut. Check the timing belt to identify the manufacturer rotation marks, and in case it seems to be reusable, put it back in the same position to avoid faster wear. Unbolt the belt using the sprockets, taking caution to maintain the sprockets in their correct timing position and examine the belt and sprockets to confirm the absence of any contamination or wear. Although the belt may be questionable, and may have covered over 36,000 miles, it is still better to replace the belt. In case installing the timing belt is not going to be done right away, put a warning sign on the steering wheel so that no one can start the engine. To install, make sure the timing marks of the crankshaft, camshaft, and intermediate shaft are positioned at TDC on the No. 1 cylinder. Install the timing belt by looping around the crankshaft sprocker with the ribbed drive belt pulley (temporarily) in place and ensure that the timing marks are correct. Insert the timing belt teeth into the crankshaft sprocket and position it across the intermediate shaft and camshaft sprockets taking note of direction of rotation markings. Bring the flat part of the belt on the roller with a tensioner, and ensure that the run in the front is straight, and then tighten the belt by turning the tensioner clockwise. Check the tension by turning the belt between the intermediate shaft and the camshaft sprockets making sure that they can turn 90 degrees. After the proper tension is determined, screw the tensioner locknut, turn the crankshaft two full revolutions to align the timing marks again and re-adjust the belt tension. Lastly, re-fit the ribbed drive belt pulley, water pump pulley, tighten the drive belts and disturb the negative battery cable.

- Q: What precautions should be taken regarding Cam Gear and Timing Belt during the replacement procedure on Volkswagen Jetta?A:This procedure should be done with caution because the rotating of crankshaft or the camshaft alone with the timing belt released may damage the valves, a minimum of rotation of the camshaft is only necessary to make sure that the marks of the sprockets match with the rear timing belt cover. The battery has to be disconnected by re-educating oneself on a number of systems to work with. This is a procedure that can be used on the 2.0L (CBPA) and 1.4L (CZTA, DGXA) engines. The complexity of the timing system requires a lot of experience; any error may cause serious damage to the engine, and it is better to use the services of a specialist in this case. See that contact points of timing belt components are not oiled to ensure they do not fail prematurely. Start by unscrewing the negative battery cable, unscrewing the wheel bolts on the right-front, lifting the vehicle high enough, and removing the right-front wheel. Take off the splash shield, inner fender liner on the driver side and label the direction of rotation of the drive belt and remove it together with the spark plugs. Once the locking pin of tensioner is removed, place the engine at TDC position and take off coolant expansion tank, air filter housing, turbocharger pipes, and disconnection fittings of fuel hose. Detach retaining clips, upper timing belt cover, crankshaft pulley and lower cover fasteners. When using a timing belt again, indicate its direction of movement. Its timing belt is easily removed by lifting the tensioner but not bending it sharply. With the 2.0L, make certain that the crankshaft is at TDC, hold the engine and lift off the passenger side engine mount and bracket. A wrench is used to avoid crankshaft rotation when loosening the retaining bolts of the pulley. Check the tensioner pulley and idler wheel on the timing belt to ensure it works properly and examines the belt to confirm that it is not contaminated or worn out. In case of a good belt, it should be fitted back in the same position. Change the belt in case of concern about the state of it or possibility of a surpass of 60,000 miles. Prior to fueling the engine, turn the crankshaft by hand to confirm resistance that is an indication of a problem. On the 1.4L engines, be sure the crankshaft is set at TDC, replace any components removed and make sure the timing belt runs correctly around the sprockets noting rotation marks. With the 2.0L engines, make sure that the mark of the camshaft sprocket is properly aligned, loop the timing belt, and also ensure that all the timing marks are at TDC. Tension the belt, and verify that everything is in line after two full revolutions of the crankshaft, and it is important to note that the procedure should be reversed in order to reassemble.

Related Volkswagen Parts

Browse by Model

Beetle Timing Belt Cabrio Timing Belt Cabriolet Timing Belt Corrado Timing Belt EuroVan Timing Belt Fox Timing Belt Golf SportWagen Timing Belt Golf Timing Belt Jetta Timing Belt Passat Timing Belt Phaeton Timing Belt Quantum Timing Belt Rabbit Convertible Timing Belt Rabbit Timing Belt Routan Timing Belt Scirocco Timing Belt Touareg Timing Belt Vanagon Timing Belt