×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Rabbit Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Shock Absorbers found

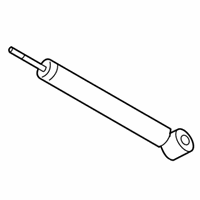

Volkswagen Rabbit Shock Part Number: 1K0-513-029-FA

$123.32 MSRP: $172.71You Save: $49.39 (29%)Ships in 1-2 Business DaysVolkswagen Rabbit Shock Absorber Part Number: 1K0-513-029-FB

$123.32 MSRP: $172.71You Save: $49.39 (29%)Ships in 1-2 Business DaysVolkswagen Rabbit Shock Absorber Part Number: 1K0-513-029-HL

$117.44 MSRP: $164.49You Save: $47.05 (29%)Ships in 1-2 Business DaysVolkswagen Rabbit Shock Part Number: 171-513-033-R

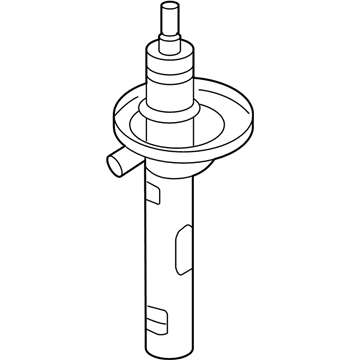

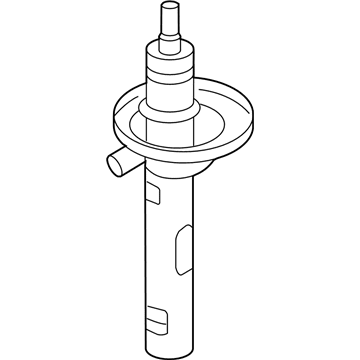

$136.41 MSRP: $191.05You Save: $54.64 (29%)Volkswagen Rabbit Strut Part Number: 1T0-413-031-HN

$161.36 MSRP: $226.00You Save: $64.64 (29%)Ships in 1-2 Business DaysVolkswagen Rabbit Strut Part Number: 1T0-413-031-HP

$161.36 MSRP: $226.00You Save: $64.64 (29%)Ships in 1-2 Business Days

Volkswagen Rabbit Shock Absorber

Choose OEM Shock Absorber for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Shock Absorber on your Rabbit, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Rabbit parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Rabbit Shock Absorber Parts and Q&A

- Q: How to replace the rear shock absorbers on Volkswagen Rabbit?A:Loosen the rear wheel bolts and chock the front wheels to prevent the vehicle from rolling, then raise the rear and support it securely on jackstands before removing the rear wheel. For models with multi-link rear suspension, support the lower Control Arm with a floor jack positioned near the outer end of the arm, while for 2011 Jetta models with a torsion beam rear axle, place the floor jack below the coil spring pocket. Remove the shock absorber lower mounting fastener, followed by the upper mounting fasteners to take out the shock absorber. Guide the new shock absorber into position and install the upper mounting bolts along with a new lower mounting bolt (and nut for 2011 Jetta models with a torsion beam axle), but do not tighten the lower fastener yet. Tighten the upper mounting bolts to the specified torque, then raise the rear axle to simulate normal ride height and tighten the lower mounting bolt/nut to the specified torque, ensuring the long collar of the shock absorber faces the rear and sits into the center of the knuckle housing arm seat. Repeat the process for the other rear shock absorber, then install the wheels and lower the vehicle, tightening the wheel bolts to the specified torque.

- Q: What actions are necessary if the coil springs and shock absorber in the front suspension strut show signs of wear on Volkswagen Rabbit?A:When the front suspension strut or coil springs are exhibiting evidence of wear (e.g. fluid leakage, lack of damping action, sagging, or cracked coil springs), then they are to be removed and repaired accordingly. The struts are not serviceable and may be replaced when faulty, and the springs and other parts can be changed on an individual basis. Components of both sides need to be replaced at the same time to ensure the balanced attributes of both sides of the vehicle. After the assembly has been taken out of the car, remove all the dirt on the outside and place it in a vise. Install the coil spring compressor tools, not forgetting to ensure they are seated fully and tighten the spring to a point where all tension has been removed in the upper mount. Using an Allen key, loosen the strut piston rod and loosen the thrust bearing retaining nut using a box-end wrench. Persist with the withdrawal of the top mount, upper spring seat, then spring, then the boot, bearing and bump stop. Should there be a need to install a new spring, one should be careful when removing the old spring out of the compressor or when using it again, the spring may be under compression. The strut assembly being fully disassembled, inspect all parts, wear, and make sure the bearing is operating smoothly and replace parts where necessary. Look at the strut to see whether it is leaking, the piston rod to see whether it is pitting, and the strut body to see whether it is damaged. Check the working of the strut by passing the piston in both full and short strokes, and should the resistance be jerky or jumping, or the wear or damage of the strut evident: replace the strut. The sequence of reassembly is in the opposite order as disassembly, the coil springs must be fitted in place with the paint mark facing downward, the ends of the coil springs must be correctly in place in the lower and upper seats and the piston rod nut tightened to the required level.