×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

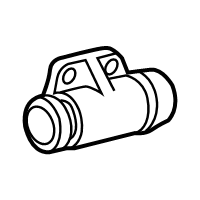

Genuine Volkswagen Wheel Cylinder

Brake Wheel Cylinder- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Wheel Cylinders found

Volkswagen Wheel Cylinder Part Number: 1EA-611-053-F

$34.92 MSRP: $58.20You Save: $23.28 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Cylinder

Volkswagen Wheel Cylinder Part Number: 5C0-611-053-A

$57.06 MSRP: $79.24You Save: $22.18 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Cylinder

- Replaces: 5C0-611-053

Volkswagen Wheel Cylinder Part Number: 1H0-611-053-B

$43.56 MSRP: $60.50You Save: $16.94 (28%)Product Specifications- Other Name: Brake Cylinder

Volkswagen Wheel Cylinder Part Number: 1J0-611-053

$46.51 MSRP: $64.60You Save: $18.09 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Cylinder

- Replaces: 3A0-611-053

Volkswagen Wheel Cylinder Part Number: 6Q0-611-053-B

$53.92 MSRP: $74.89You Save: $20.97 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Brake Cylinder

- Replaces: 1H0-611-053

Volkswagen Wheel Cylinder Part Number: 211-611-047-F

$57.24 MSRP: $79.50You Save: $22.26 (28%)Product Specifications- Other Name: Brake Cylinder

Volkswagen Wheel Cylinder Part Number: 721-611-047

$78.54 MSRP: $110.00You Save: $31.46 (29%)Product Specifications- Other Name: Brake Cylinder

Volkswagen Wheel Cylinder

A total system failure could result from a malfunctioning Volkswagen Wheel Cylinder, reducing driving comfort and posing a danger. It is for this reason that you should conduct regular inspections and replace such components in good time to enable your car to run smoothly and safely. OEM (Original Equipment Manufacturer) Volkswagen Wheel Cylinders are perfect for motorists because they are the best quality parts produced as per the manufacturer's specifications; hence, they perform well and are reliable too, thus helping to retain the car's initial functionality as well as safety features. At VWPartsGiant.com, our genuine Volkswagen Wheel Cylinder supply indicates how much we care about the health of your vehicle. Additionally, our stock is vast, so every product will be easily accessible to you for finding and swapping without fear of making mistakes. With our user-friendly online catalog, it takes no time to identify the right spare part. Therefore, convenience accompanies servicing or maintaining a motorcar. You can rely on our OEM Volkswagen Wheel Cylinder to sustain the performance of your automobile.

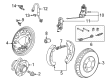

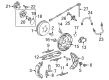

Volkswagen Wheel Cylinder Parts and Q&A

- Q: How to remove and install a wheel cylinder on a brake drum on Volkswagen Jetta?A:Removing the brake drum To take the brake drum, spray the brake assembly with brake cleaner and then empty the lubricant in a drip pan. With pliers carefully dislock the upper brake shoe return spring and take it out of both brake shoes then pull away the upper ends of the shoes out of the wheel cylinder to disconnect them to the pistons. Reduce the loss of fluids by limiting the reservoir cap of the master cylinder by covering it with cellophane. Assuming you have one, a flare nut wrench; loosen the nut screw of the brake line fitting at the wheel cylinder, then take the line out, very carefully and wipe the end off so as not to get dirt in it. Undo the retaining bolt of the wheel cylinder at the rear of the backing plate and remove the cylinder and be sure not to spill the brake fluid on the linings of the brake shoes. To install, the mating surfaces of the backing plate and the wheel cylinder should be clean, the brake shoes should be spread, and the wheel cylinder should be installed. Connect the brake line with screwing in the fitting nut a few turns to make sure that the thread is engaged and then install the wheel cylinder retaining bolt and tighten it to the required torque, fastening the fitting nut of the brake line. Take cellophane out of the master cylinder reservoir cap, make sure that the brake shoe is in the right position in the cylinder pistons and attach the brake shoe upper return spring with a screwdriver. Lastly, install the drum and bleed the brake hydraulic system, but this time care should be taken not to lose much fluid, and that should only require bleeding the concerned rear brake.

- Q: How to remove the wheel cylinder from the brake drum on Volkswagen Cabrio?A:The brake drum can be removed by first washing the brake assembly using brake system cleaner and letting the excess liquid to drain in a drip pan. It is important to take the upper brake shoe return spring out of both brake shoe with a plier and then remove it to ensure that the upper ends of the shoes are not attached to the wheel cylinder. Reduce the loss of fluids by capping the master cylinder reservoir with cellophane. Unscrew the fitting nut of the brake line at the wheel cylinder, shake the line out and wipe off the fluid spilled off, and then wipe the end of the line to keep dust out. Unscrew the two bolts holding the wheel cylinders together at the back of the supporting plate off and take the wheel cylinder out, making sure that the brake shoe linings are not contaminated with brake fluid. Wipe the wheel cylinder with brake system cleaner and then remove rubber dust seals at the ends of cylinder body. In case the pistons fail to eject because of the pressure of coil springs, tap the end of the cylinder body on a piece of wood to eject. Search the surfaces of the pistons and bores of the pistons, to see whether they are scored or in contact with metal; and, in case they are, change the complete wheel cylinder assembly. In case the pistons and bores are well-kept, you can replace the seals and purchase a repair kit with the required replacing components. Unscrew the seals of the pistons, making sure that they are properly oriented, lubricate the new piston seals with clean brake fluid and put them in place with the lips facing the inside. Wipe the pistons with clean brake fluid, fit the spring to the cylinder and pop the pistons into the cylinder bores with a twisting motion. Fit the dust seals and make sure that the pistons are free to move. Make sure the backing plate and the wheel cylinder mating surfaces are clean, position the brake shoes and position the wheel cylinder. Install the brake line and screw the fitting nut a few times to begin threading; then install the two wheel cylinder retaining bolts and tighten them to the required torque, then screw the fitting nut of the brake line tighter. Take off the cellophane in the master cylinder reservoir, the brake shoes on the pistons of the cylinder must be properly aligned and the brake shoe upper return spring should be fitted properly with the help of a screwdriver. Lastly, install the brake drum and bleed the brake hydraulic system, but here one should make certain of minimizing the loss of fluid that may require bleeding the associated rear brake.