×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

174 Brake Calipers found

Volkswagen Caliper Part Number: 3QF-615-124

$90.14 MSRP: $126.24You Save: $36.10 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Volkswagen Caliper Part Number: 5QM-615-423-B

$137.43 MSRP: $192.49You Save: $55.06 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper Assembly

- Position: Left

Volkswagen Caliper Part Number: 5QM-615-424-B

$137.43 MSRP: $192.49You Save: $55.06 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper Assembly

- Position: Right

Volkswagen Caliper Part Number: 5Q0-615-423-E-SL7

$163.67 MSRP: $229.24You Save: $65.57 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Housing

Volkswagen Caliper Part Number: 3QF-615-123

$118.56 MSRP: $166.05You Save: $47.49 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Volkswagen Caliper Part Number: 357-615-124-AX

$105.25 MSRP: $146.67You Save: $41.42 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

- Replaces: 357-615-124-A

Volkswagen Caliper Part Number: 7B0-615-423-F

$137.56 MSRP: $192.67You Save: $55.11 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

- Replaces: 7B0-615-423-B, 7B0-615-423-E

Volkswagen Caliper Part Number: 7B0-615-424-F

$137.56 MSRP: $192.67You Save: $55.11 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

- Replaces: 7B0-615-424-B, 7B0-615-424-E

Volkswagen Caliper Part Number: 357-615-123-AX

$114.77 MSRP: $160.00You Save: $45.23 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

- Replaces: 357-615-123-A

Volkswagen Caliper Part Number: 5QM-615-423-A

$189.91 MSRP: $265.99You Save: $76.08 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper Assembly

- Position: Left

- Replaces: 5Q0-615-423-B

Volkswagen Caliper Part Number: 3QF-615-124-A

$204.91 MSRP: $286.99You Save: $82.08 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Volkswagen Caliper Part Number: 5QM-615-424-A

$204.91 MSRP: $286.99You Save: $82.08 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper Assembly

- Position: Right

- Replaces: 5Q0-615-424-B

Volkswagen Caliper Part Number: 1J0-615-424-A

$171.36 MSRP: $240.00You Save: $68.64 (29%)Product Specifications- Position: Right

Volkswagen Caliper Part Number: 5WA-615-423-B-QC8

$219.90 MSRP: $307.99You Save: $88.09 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Housing

Volkswagen Caliper Part Number: 1H0-615-124-C

$177.04 MSRP: $247.95You Save: $70.91 (29%)Product Specifications- Replaces: 171-615-124-B, 1H0-615-124-A

Volkswagen Caliper Part Number: 8V0-615-123

$223.65 MSRP: $313.24You Save: $89.59 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Volkswagen Caliper Part Number: 1J0-615-423

$180.88 MSRP: $253.33You Save: $72.45 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

- Replaces: 8N0-615-423

Volkswagen Caliper Part Number: 1J0-615-424

$180.88 MSRP: $253.33You Save: $72.45 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Volkswagen Caliper Part Number: 1H0-615-123-C

$186.32 MSRP: $260.95You Save: $74.63 (29%)Product Specifications- Replaces: 171-615-123-B, 1H0-615-123-A

Volkswagen Caliper Part Number: 561-615-124-B

$237.39 MSRP: $332.49You Save: $95.10 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

| Page 1 of 9 |Next >

1-20 of 174 Results

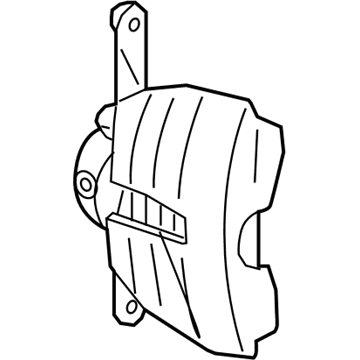

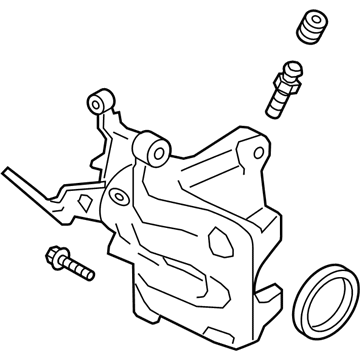

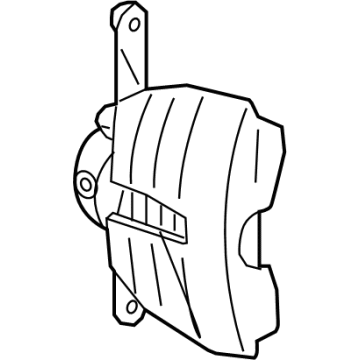

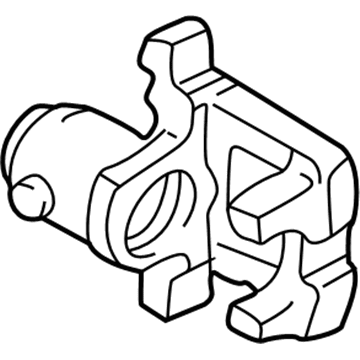

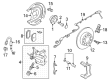

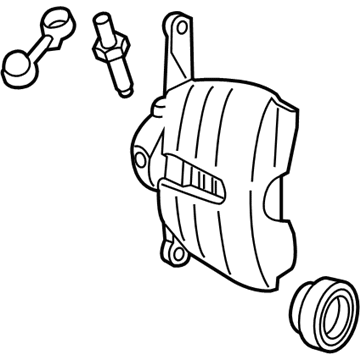

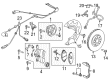

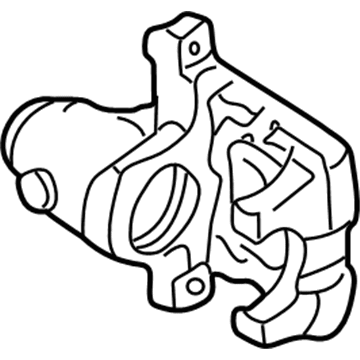

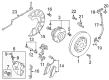

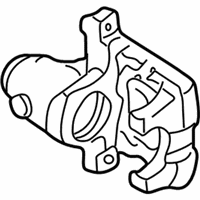

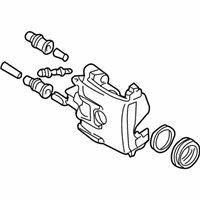

Volkswagen Brake Caliper

It's needless to say, the Volkswagen brake caliper is the most important part of the disc brake system. In some cars, it is found in the front, while in others, it is at the rear. The brake fluid flows into the caliper when you drive your car and depress the brake pedal. Consequently, this fluid causes pressure against the piston inside, which makes contact with the rotor to stop your car. Nevertheless, with time and heat effects, brake calipers start becoming rusty, thereby leaking brake fluid from them. If you see any leaking of brake fluid here, then you know your braking system needs an overhaul because there might be a problem somewhere surrounding its functioning.

OEM (Original Equipment Manufacturer) Volkswagen Brake Calipers are perfect for motorists because they are the best quality parts produced as per the manufacturer's specifications; hence, they perform well and are reliable too, thus helping to retain the car's initial functionality as well as safety features. At VWPartsGiant.com, our genuine Volkswagen Brake Caliper supply indicates how much we care about the health of your vehicle. Additionally, our stock is vast, so every product will be easily accessible to you for finding and swapping without fear of making mistakes. With our user-friendly online catalog, it takes no time to identify the right spare part. Therefore, convenience accompanies servicing or maintaining a motorcar. You can rely on our OEM Volkswagen Brake Caliper to sustain the performance of your automobile.

Volkswagen Brake Caliper Parts and Q&A

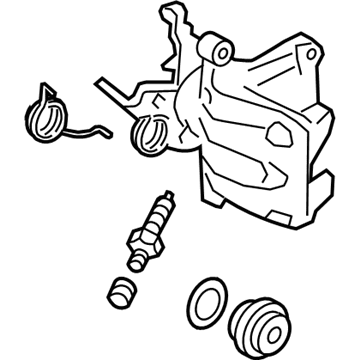

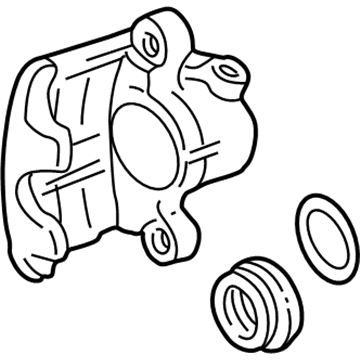

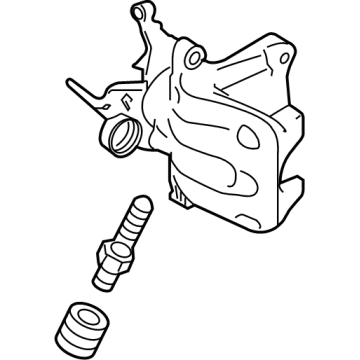

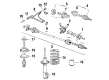

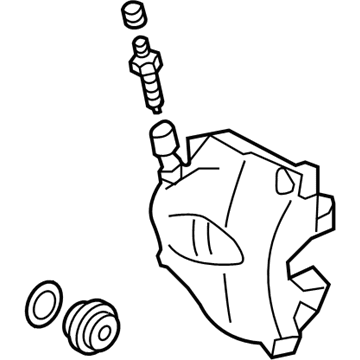

- Q: What steps should be taken when overhauling front brake calipers due to issues like fluid leaks or a stuck piston on Volkswagen Cabrio?A:In case overhaul has been recommended by the problems such as fluid leakage, frozen piston, or broken bleeder screw, check every possible solution before commencing the process. Calipers that are new and factory rebuilt are exchanged on a basis of exchange, making the job easy. When rebuilding calipers, always have rebuild kits on hand and in either case, rebuild or replace these calipers in pairs. The first step is to loosen the lug bolts that hold the wheel, to engage the parking brake, to raise up the front part of the car and make sure that the front part is put on jack stands and then remove the relevant wheel. Wipe the brake system using brake system cleaner and leave the moisture to dry in a drip pan. Reduce the loss of fluids by taking out the master cylinder reservoir cap and covering it with cellophane. Wipe the surrounding of the fitting and unscrew the brake hose fitting nut without und screwing the hose off the caliper. Removing the caliper to get access, do not unconnect the brake hose. Unscrew the caliper in the brake hose, then remove the brake pad, and also take the caliper out of the vehicle. Again wipe the caliper with the brake system cleaner, kick off the partially ejected piston and remove the dust seal. In case the piston cannot be drawn manually, apply compressed air in a cautious manner and a cushion should be provided to avoid breakages. Carefully remove the piston hydraulic seal using a plastic or wooden object so as not to damage the caliper bore. Wipe all the parts using isopropyl alcohol, clean brake fluid, or brake system cleaner, and leave to dry. On VW calipers, remove the spacers of the caliper body bushings and on Girling calipers, remove the guide pins and dust boots. Inspect all elements of wear or damage, especially cylinder bore and piston, which must be changed in case of a scratch, wear or corrosion. In case the assembly can be used any more, get the proper repair kit and re-assemble all the rubber seals, dust covers and caps that have been disturbed during the dismantling. It is essential to make sure that all parts are clean and dry when reassembling, witness the piston and new piston seal in clean brake fluid and apply clean fluid to the surface of the cylinder bore. Insert the new piston seal in the lower groove of the caliper bore with fingers making sure it fits in place. Get the new dust boot past the piston and open the flanged part to the upper groove of the cylinder pushing the piston to the bottom of the bore and passing the lip of the dust boot in. Lubricate the spacers or guide pins with grease of the repair kit or copper-based high temperature brake grease, attach the new dust boots and fix the guide pins into the mounting bracket. Lastly, tighten the caliper to the maximum and attach the brake pads and caliper, tighten the brake line fitting nut, take off the cellophane in the master cylinder reservoir and bleed the hydraulic system. Once there has been minimum loss of brake fluid, then only the concerned front brake should be bled. Install the wheel, drop the vehicle on the ground, and screw the wheel bolts to the required torque.

- Q: How to properly remove and install a brake caliper without damaging the brake hose on Volkswagen Jetta?A:When you are removing the caliper to gain access to other parts, do not disconnect the hose rather hang the caliper using a bit of wire such that the brake hose is not damaged. First, it is important to loosen the front or rear wheel bolts, elevate the vehicle, and place it safely on jackstands and block the opposite end wheels. Take out the front wheel or rear wheel. To remove the cable of the parking brake lever and the bracket of rear caliper, look after pushing the lever in by hand so that the ball end of the cable could be worked off, and then pull the cable off the bracket with a box-end wrench or pliers to compress the tabs holding them on. To access a front caliper, or ZOH BIR 38 rear caliper, loosen the banjo fitting bolt and dis-attach the brake hose connector to the caliper, being careful not to lose the sealing washers, or lose all the open fittings to fluid loss and contamination. In the case of a Cl 38 rear caliper loosen the brake line fitting nut in the brake hose fitting with a flare nut wrench, then screw the clip holding the brake hose to its bracket open and disconnect the hose by twisting off the fitting to avoid fluid leakages. Lastly, unscrew the caliper guide pins or mounting bolts and unscrew the caliper. The opposite to removal is installation; in the case of a front caliper, apply new sealing washers on each side of the inlet brake hose fitting and attach the fasteners to the required torque. Bleed the brake system after it is installed, inspect the leaks of the hose attachment, pump the brake pedal multiple times prior to driving and test the brakes thoroughly before it is reintroduced to the regular use again.

Related Volkswagen Parts

Browse by Model

Arteon Brake Caliper Atlas Brake Caliper Atlas Cross Sport Brake Caliper Beetle Brake Caliper CC Brake Caliper Cabrio Brake Caliper Cabriolet Brake Caliper Corrado Brake Caliper Eos Brake Caliper EuroVan Brake Caliper Fox Brake Caliper GTI Brake Caliper Golf Alltrack Brake Caliper Golf Brake Caliper Golf R Brake Caliper Golf SportWagen Brake Caliper ID.4 Brake Caliper Jetta Brake Caliper Passat Brake Caliper Phaeton Brake Caliper Quantum Brake Caliper R32 Brake Caliper Rabbit Brake Caliper Rabbit Convertible Brake Caliper Routan Brake Caliper Scirocco Brake Caliper Taos Brake Caliper Tiguan Brake Caliper Tiguan Limited Brake Caliper Touareg Brake Caliper Vanagon Brake Caliper e-Golf Brake Caliper