×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

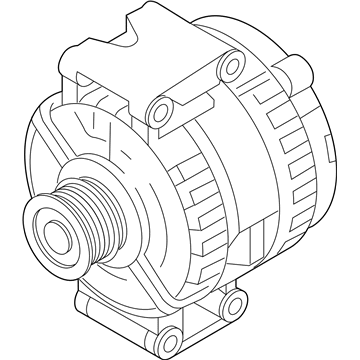

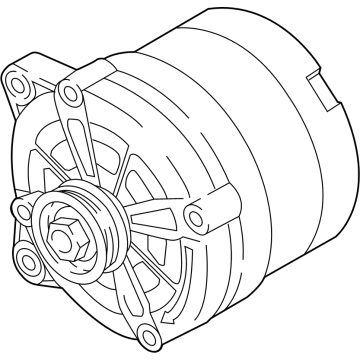

Genuine Volkswagen Alternator

Generator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

124 Alternators found

Volkswagen Alternator Part Number: 7B0-903-015-A

$431.42 MSRP: $589.37You Save: $157.95 (27%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 7B0-903-015-B

$468.15 MSRP: $639.55You Save: $171.40 (27%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 7B0-903-015

Volkswagen Alternator Part Number: 7B0-998-015-C

$733.51 MSRP: $1002.06You Save: $268.55 (27%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Repair Kit; Alternator

- Replaces: 7B0-998-015, 7B0-998-015-A, 7B0-998-015-B, 7B0-903-015-C, 7B0-903-015-CX-RMN

Volkswagen Alternator Part Number: 175-903-023-LX

$151.24 MSRP: $195.52You Save: $44.28 (23%)Volkswagen Alternator Part Number: 03H-903-026-A

$195.15 MSRP: $252.29You Save: $57.14 (23%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 06K-903-015-D

$199.91 MSRP: $258.45You Save: $58.54 (23%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 06F-903-023-R

$192.77 MSRP: $249.22You Save: $56.45 (23%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 05E-903-026-L

$262.29 MSRP: $330.75You Save: $68.46 (21%)Ships in 1-2 Business DaysProduct Specifications- Replaced by: 05E-903-027-A

Volkswagen Alternator Part Number: 05E-903-027-A

$262.29 MSRP: $330.75You Save: $68.46 (21%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 034-903-017-X

$289.18 MSRP: $363.88You Save: $74.70 (21%)Volkswagen Alternator Part Number: 028-903-025-H

$352.76 MSRP: $444.85You Save: $92.09 (21%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 06K-903-015-B

$362.94 MSRP: $457.68You Save: $94.74 (21%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 068-903-017-QX

$376.76 MSRP: $475.00You Save: $98.24 (21%)Volkswagen Alternator Part Number: 03H-903-023-M

$384.29 MSRP: $484.60You Save: $100.31 (21%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 06K-903-026-C

$405.64 MSRP: $511.53You Save: $105.89 (21%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 06K-903-026-L

$423.94 MSRP: $534.60You Save: $110.66 (21%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 028-903-025-G

$428.22 MSRP: $540.00You Save: $111.78 (21%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 06K-903-026-D

$274.91 MSRP: $346.68You Save: $71.77 (21%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 03H-903-026-B

$439.19 MSRP: $553.83You Save: $114.64 (21%)Ships in 1-2 Business DaysVolkswagen Alternator Part Number: 03H-903-026-J

$439.19 MSRP: $553.87You Save: $114.68 (21%)Ships in 1-2 Business Days

| Page 1 of 7 |Next >

1-20 of 124 Results

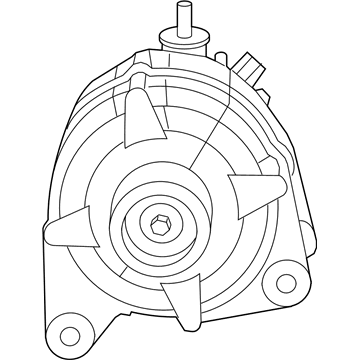

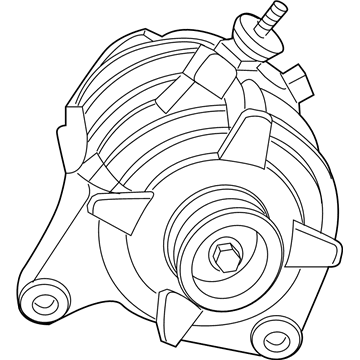

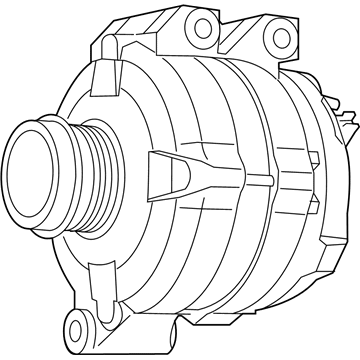

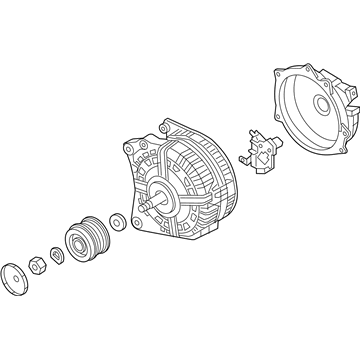

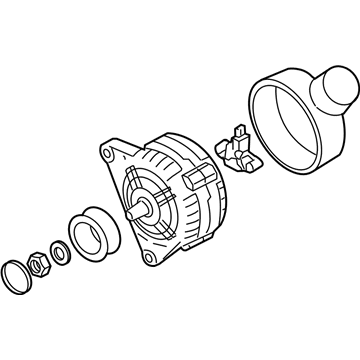

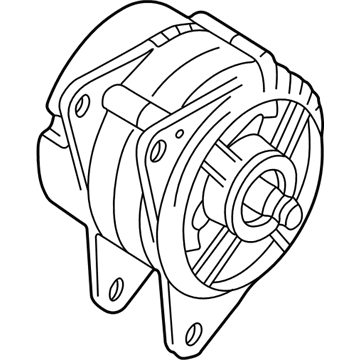

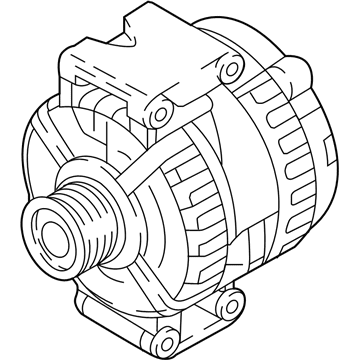

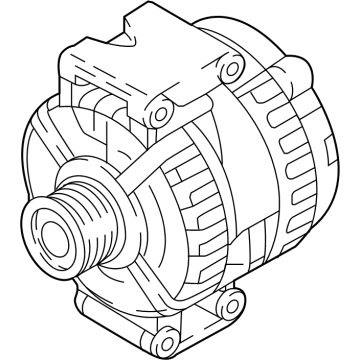

Volkswagen Alternator

The Volkswagen alternator cooperates with the battery to produce power for the automobile's electrical parts, such as the dashboard instrumentation, interior light, and exterior light. Normally situated in or near the front section of an engine, it is driven by the crankshaft or belt. This mechanism converts kinetic energy from moving pistons into electrical energy for the battery. Identifying a problem with the alternator is not easy because it can cause a variety of issues. Furthermore, a bad alternator goes out gradually until all car electric accessories go off, then breaks down altogether.

OEM (Original Equipment Manufacturer) Volkswagen Alternators are perfect for motorists because they are the best quality parts produced as per the manufacturer's specifications; hence, they perform well and are reliable too, thus helping to retain the car's initial functionality as well as safety features. At VWPartsGiant.com, our genuine Volkswagen Alternator supply indicates how much we care about the health of your vehicle. Additionally, our stock is vast, so every product will be easily accessible to you for finding and swapping without fear of making mistakes. With our user-friendly online catalog, it takes no time to identify the right spare part. Therefore, convenience accompanies servicing or maintaining a motorcar. You can rely on our OEM Volkswagen Alternator to sustain the performance of your automobile.

Volkswagen Alternator Parts and Q&A

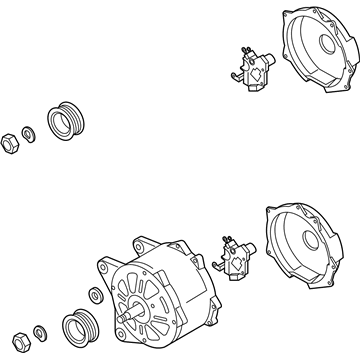

- Q: How to remove and inspect the alternator and its components on Volkswagen Cabrio?A:Take out the alternator and put it on a clean working surface with the pulley side downwards. Take the screws that retain it out, push the clips apart, and scratch off the plastic cover at the back of the alternator. Unscrew and remove screws of the brush holder/voltage regulator module and then raise the module up off the alternator. Measure the free length of the brush contacts between the emblem marked by the manufacturer on the side face to the shallowest point of the curved end face of the brush. Take out the retaining screws and scrap the brush contact and verify the reading with the specifications; change the module when the brushes are too worn out below the minimum limit. Check the slip rings on ends of alternator shaft and in the event they seem too worn, burnt, or pitted, replace them and seek the advice of automobile electrical system expert. Disassembling the alternator should be reversed, and the alternator should be reassembled and installed.

- Q: How to remove and reinstall the alternator and generator assembly on Volkswagen Transporter?A:A fan and generator have a common shaft, and their removal simultaneously are necessary out of the engine, which starts with the carburettor being removed and the fan housing raised, thus necessitating the removal of the thermostat. The fan belt should then be removed, then the battery should be disconnected to prevent short circuit accidents, the air cleaner removed and wires at the top of the generator disconnected, they must be labelled so that they can be put back in place. The generator is attached to the pedestal with a metal strap; the clamping bolt on the right must be unscrewed, and the strap pushed off. When the engine is out of the car, it is recommended to loosen the fan nut beforehand, with the notch in the fan belt pulley which holds the shaft during the loosening of the nut. The fan housing can be lifted up after removing the four bolts used to fix the fan cover plates to the fan housing to extract the generator and fan assembly. The fan nut will be removed by clamping the generator body in a vice, with the assembly removed, the fan belt pulley should be reassembled and the fan nut should be removed. After removing the nut, the dished lock washer may then be taken out, as well as the fan, thrust washer, spacer washers, the fan hub which is keyed into the shaft. The fan cover plates are attached to the generator by the use of two nuts on the ends of the generator by using bolts so that the inner cover slot is facing downwards and the dished cover fits into the fan housing to optimally ensure that the air is being drawn out of the fan. It is also important that the reassembling process is done thoughtfully beginning with the outer cover plate and then the stiffening plate and then the inner cover plate whereby the peripheral slot should face the bottom of the fan housing. The dynamo shaft requires the spacer ring that prevents jamming and then the fans hub and spacer washers can be replaced by the fan. The special lock washer and nut would then be changed with the raised edges of the dished lock washer facing the nut. The nut should be firmly clamped so as to make the hub fully settled, the distance between the fan and the cover plate should be at least 2 mm (0.080 ins); this can be corrected by adding or taking away shims. Latter torque of fan nut is recommended to be 43lb ft. The re-installation of generator/fan assembly is followed by the removal procedure in reverse but one must take care not to distort them and to have everything in place before tightening. The strap must be used to fit the shapes of the pedestal bracket, and when all is tightened the fan must be rotated to ensure there is no contact, which would mean it is not aligned or bent. The subsequent models have a reduced pulley diameter of 170 mm, and a revised fan housing with an air deflector ring.

Related Volkswagen Parts

Browse by Model

Arteon Alternator Atlas Alternator Atlas Cross Sport Alternator Beetle Alternator CC Alternator Cabrio Alternator Cabriolet Alternator Corrado Alternator Eos Alternator EuroVan Alternator Fox Alternator GTI Alternator Golf Alltrack Alternator Golf Alternator Golf R Alternator Golf SportWagen Alternator Jetta Alternator Passat Alternator Phaeton Alternator Quantum Alternator R32 Alternator Rabbit Alternator Routan Alternator Scirocco Alternator Taos Alternator Tiguan Alternator Tiguan Limited Alternator Touareg Alternator Transporter Alternator Vanagon Alternator