×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Cabrio Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Brake Master Cylinders found

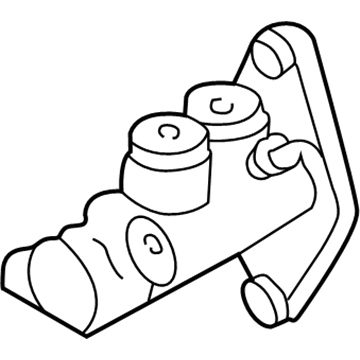

Volkswagen Cabrio Master Cylinder Part Number: 3A1-698-019

$284.02 MSRP: $388.00You Save: $103.98 (27%)Ships in 1-2 Business DaysVolkswagen Cabrio Master Cylinder Part Number: 1H1-698-019-A

$365.41 MSRP: $499.20You Save: $133.79 (27%)

Volkswagen Cabrio Brake Master Cylinder

Choose OEM Brake Master Cylinder for superior quality and long-lasting durability. They match the Volkswagen's factory specifications exactly and pass strict quality control. If you plan to replace Brake Master Cylinder on your Cabrio, put OEM at the top of your list. You'll get the right fit, reliable performance, and peace of mind. We stock an extensive inventory of genuine Volkswagen Cabrio parts. It is easy to find what you need. You will love our competitive prices that help you save. No more hassle with returns or guesswork. Every part includes a warranty straight from the manufacturer. Get trusted quality, strong durability, and real value today.

Volkswagen Cabrio Brake Master Cylinder Parts and Q&A

- Q: How to disconnect and replace the Brake Master Cylinder in a brake system on Volkswagen Cabrio?A:Unscrew the battery negative terminal, and remove, where necessary, the air inlet duct to allow better access to the master cylinder. Take off the master cylinder reservoir cap and drain the brake fluid out of the reservoir with a syringe or an old poultry baster and make sure not to siphon off by mouth as it is a toxic fluid. Instead, open a bleed screw in the system and press the brake pedal very hard with your fingers to get the fluid out in a plastic tube. Disconnect electrical connector on level sender brake fluid unit. Wipe down all around the fittings of the brake line on the master cylinder, and put absorbent rags underneath to take up any fluid. Record the right positions of fittings, unscrew the fitting nuts and remove the lines with care screwing off the end or covering with tape to reduce the loss of fluid and entry of dirt. Rinse any spilled liquid using cold water. Relax and loosen the two nuts and washers holding the master cylinder to the power Brake Booster and then remove the unit out of the engine compartment and also dispose the O-ring at the back of the master cylinder. In case of a malfunction of the master cylinder, they have to be replaced because there are no repair kits, only the seals attached to the fluid reservoir should be changed. In case such seals are worn out, take out the reservoir, and install new lubricated seals, and push the reservoir into place. Wipe the mating surfaces of the master cylinder and booster unit, install a new O-ring in the master cylinder groove and adjust the master cylinder on the booster unit and make sure that it fits in the pushrod correctly. Install the mounting nuts and washers to the recommended torque, install the brake line fittings as per requirement, fill the reservoir with new fluid and bleed the hydraulic system.