×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

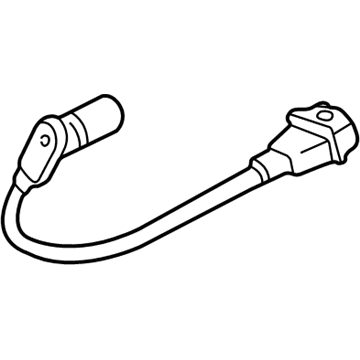

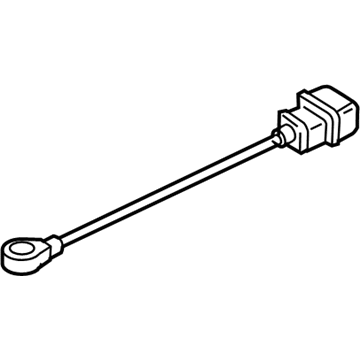

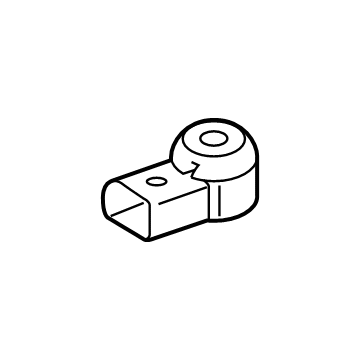

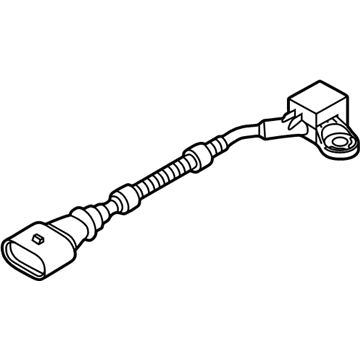

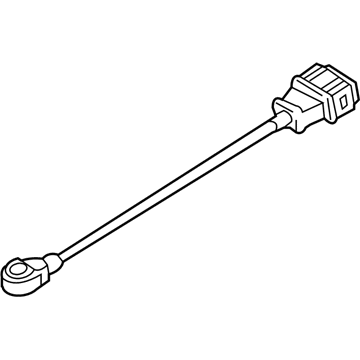

Genuine Volkswagen Knock Sensor

Engine Knock Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

28 Knock Sensors found

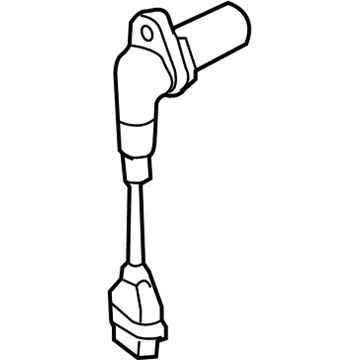

Volkswagen Knock Sensor Part Number: 07D-905-376-C

$35.70 MSRP: $59.50You Save: $23.80 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 07D-905-376-D

$35.70 MSRP: $59.50You Save: $23.80 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 07D-905-376-E

$35.70 MSRP: $59.50You Save: $23.80 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 07D-905-376-F

$35.70 MSRP: $59.50You Save: $23.80 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

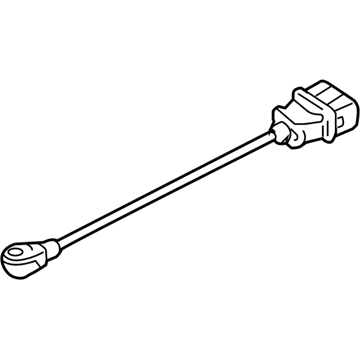

Volkswagen Knock Sensor Part Number: 037-905-377-B

$46.80 MSRP: $65.00You Save: $18.20 (28%)Product Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 7B0-905-377-C

$55.82 MSRP: $77.53You Save: $21.71 (28%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 030-905-377-F

$4.22 MSRP: $6.92You Save: $2.70 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 078-905-377

$89.96 MSRP: $126.00You Save: $36.04 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 07K-905-377-D

$96.38 MSRP: $134.98You Save: $38.60 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

- Replaces: 07K-905-377, 07K-905-377-B

Volkswagen Knock Sensor Part Number: 07K-905-377-E

$98.76 MSRP: $138.32You Save: $39.56 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

- Replaces: 07K-905-377-A, 07K-905-377-C

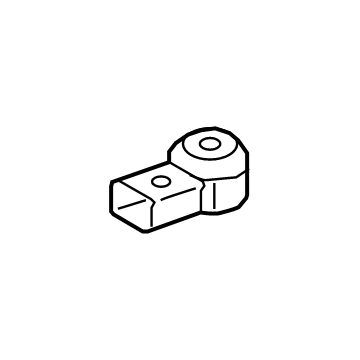

Volkswagen Knock Sensor Part Number: 06C-905-377

$98.76 MSRP: $138.32You Save: $39.56 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 06F-905-377

$99.95 MSRP: $139.98You Save: $40.03 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 06K-905-377-E

$101.14 MSRP: $141.65You Save: $40.51 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor; Knock Sensor

Volkswagen Sensor Part Number: 054-905-377-G

$102.33 MSRP: $143.32You Save: $40.99 (29%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 054-905-377

Volkswagen Knock Sensor Part Number: 06E-905-377-J

$102.33 MSRP: $143.32You Save: $40.99 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor; Knock Sensor

- Position: Left

Volkswagen Knock Sensor Part Number: 06E-905-377-K

$102.33 MSRP: $143.32You Save: $40.99 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor; Knock Sensor

- Position: Right

Volkswagen Knock Sensor Part Number: 079-905-377-E

$102.33 MSRP: $143.32You Save: $40.99 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

- Replaces: 079-905-376-C, 079-905-377-A

Volkswagen Knock Sensor Part Number: 07D-905-377

$102.33 MSRP: $143.32You Save: $40.99 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

Volkswagen Knock Sensor Part Number: 7B0-905-377-E

$158.96 MSRP: $223.38You Save: $64.42 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor; Knock Sensor

- Replaces: 7B0-905-377

Volkswagen Knock Sensor Part Number: 7B0-905-377-D

$115.58 MSRP: $161.88You Save: $46.30 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor

- Replaces: 7B0-905-377-A

| Page 1 of 2 |Next >

1-20 of 28 Results

Volkswagen Knock Sensor

When fuel is not ignited correctly, the regular cycle of the engine will be interrupted, which might damage some parts inside it. For this reason, a knock sensor is installed, a piezo-electric component designed to allow the engine to run with ignition timing as far ahead as possible. The Volkswagen knock sensor picks up a rapid change in pressure on the cylinder walls and sends this message to the engine control unit for adjustment of ignition time. It is essential to check regularly and replace knock sensors if necessary.

OEM (Original Equipment Manufacturer) Volkswagen Knock Sensors are perfect for motorists because they are the best quality parts produced as per the manufacturer's specifications; hence, they perform well and are reliable too, thus helping to retain the car's initial functionality as well as safety features. At VWPartsGiant.com, our genuine Volkswagen Knock Sensor supply indicates how much we care about the health of your vehicle. Additionally, our stock is vast, so every product will be easily accessible to you for finding and swapping without fear of making mistakes. With our user-friendly online catalog, it takes no time to identify the right spare part. Therefore, convenience accompanies servicing or maintaining a motorcar. You can rely on our OEM Volkswagen Knock Sensor to sustain the performance of your automobile.

Volkswagen Knock Sensor Parts and Q&A

- Q: How can incorrectly tightening a knock sensor fastener affect its performance on Volkswagen Jetta?A:Poorly fitting a knock sensor fasteners may interfere with the functionality of the knock sensor. In case the battery is disconnected, it will be necessary to re-learn several systems until they will start to work properly. To do so, with 1.4L and 2.0L non-turbocharged engines, lift the front of the automobile and place it firmly on jackstands, and then remove the under-vehicle splash cover and the drivebelt. In 1.4L engines, get the air conditioning compressor bolts out and fix the compressor to the side. Find and unscrew the knock sensor electrical connector, pull the bolt off and unscrew the knock sensor off the block. Installation is the opposite of removing, and the knock sensor bolt should be tightened up to the torque. In 1.8L and 2.0L turbocharged engines, initial steps are the same, namely, disconnection of negative battery terminal and emptying of the cooling system. Disassemble the intake manifold and water pump, disconnect hoses and electrical connector to the Engine Temperature Control Actuator and disassemble the actuator. Disassembling The old O-rings should be discarded and the new ones installed and then the knock sensor harness connector should be disconnected, the knock sensor bolt removed and the knock sensor removed. Installation is in reverse of uninstalling and the knock sensor bolt is tightened to specifications. In the case of engines with 2.5L, the two knock sensors can be found beneath the exhaust manifold, and their electrical wires must be disconnected, the fasteners of the heat shield removed, and the screw fixing the knock sensor must be removed. Installation When fitting a knock sensor, the sensor mounting screw should be firmly screwed to its torque, and otherwise the installation process is the opposite of the removal process.

- Q: What are the functions and locations of knock sensors on Volkswagen Passat?A:The two knock sensors are fitted on all models. The knock sensors are on the left side of the engine block, directly below the intake manifold, with one knock sensor being on each side of the engine block (V6 models have a knock sensor on each side of the engine block, under the intake manifold). The knock sensor detects excessive vibration, including spark knock or ping, and the knock control system is designed to decrease spark knock during heavy detonation, and the engine is able to use maximum spark advance to give it better driveability. Knock sensors generate an AC response voltage based on the strength of the knock and the signal is diverted to the ECM which delays the timing in order to avoid detonation. In order to reach the knock sensor, take out the required parts, unplug the electrical connector, unscrew the bolt, and pull out the sensor of the engine block. Installation means the undoing of the process to remove it and tightening the knock sensor bolt to 15 ft-lbs (20Nm).

Related Volkswagen Parts

Browse by Model

Arteon Knock Sensor Beetle Knock Sensor CC Knock Sensor Cabrio Knock Sensor Corrado Knock Sensor Eos Knock Sensor EuroVan Knock Sensor GTI Knock Sensor Golf Knock Sensor Golf R Knock Sensor Jetta Knock Sensor Passat Knock Sensor Phaeton Knock Sensor Rabbit Knock Sensor Routan Knock Sensor Tiguan Knock Sensor Tiguan Limited Knock Sensor Touareg Knock Sensor