×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Volkswagen Parts

My Garage

My Account

Cart

Genuine Volkswagen Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

92 Oxygen Sensors found

Volkswagen Rear Oxygen Sensor Part Number: 06K-906-262-EA

$10.53 MSRP: $17.26You Save: $6.73 (39%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oxygen Sensor

Volkswagen Oxygen Sensor Part Number: 06K-906-262-AP

$97.34 MSRP: $136.30You Save: $38.96 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rear Oxygen Sensor

Volkswagen Oxygen Sensor Part Number: 7B0-906-265

$67.16 MSRP: $94.07You Save: $26.91 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Rear

Volkswagen Oxygen Sensor Part Number: 03H-906-262-AP

$163.99 MSRP: $229.68You Save: $65.69 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Front Oxygen Sensor

- Position: Right

Volkswagen Oxygen Sensor Part Number: 7B0-906-265-A

$68.48 MSRP: $95.92You Save: $27.44 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Volkswagen Oxygen Sensor Part Number: 06K-906-262-BF

$69.29 MSRP: $97.05You Save: $27.76 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rear Oxygen Sensor

Volkswagen Oxygen Sensor Part Number: 7B0-906-262-A

$104.87 MSRP: $146.88You Save: $42.01 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rear Oxygen Sensor

- Position: Front

Volkswagen Oxygen Sensor Part Number: 7B0-906-262-B

$145.17 MSRP: $203.32You Save: $58.15 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Upper Oxygen Sensor

- Position: Lower

Volkswagen Oxygen Sensor Part Number: 06E-906-262-K

$145.76 MSRP: $204.15You Save: $58.39 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Volkswagen Upper Oxygen Sensor Part Number: 06K-906-262-P

$117.02 MSRP: $163.90You Save: $46.88 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oxygen Sensor

- Position: Upper

Volkswagen Oxygen Sensor Part Number: 06A-906-262-BG

$145.17 MSRP: $203.32You Save: $58.15 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rear Oxygen Sensor

Volkswagen Oxygen Sensor Part Number: 1K0-998-262-AE

$148.74 MSRP: $208.32You Save: $59.58 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Oxygen Sensor Kit

- Replaces: 03L-906-262-C, 07Z-906-262-F, 06A-906-262-DE, 07Z-906-262-G, 07Z-906-262-E, 07Z-906-262-D, 03G-906-262

Volkswagen Oxygen Sensor Part Number: 06K-906-262-CF

$155.88 MSRP: $218.32You Save: $62.44 (29%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 06K-906-262-BA

Volkswagen Oxygen Sensor Part Number: 021-906-265-AH

$143.51 MSRP: $201.00You Save: $57.49 (29%)Volkswagen Oxygen Sensor Part Number: 021-906-265-AL

$147.14 MSRP: $206.08You Save: $58.94 (29%)Volkswagen Oxygen Sensor Part Number: 06E-906-262-L

$177.30 MSRP: $248.32You Save: $71.02 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Left

Volkswagen Oxygen Sensor Part Number: 051-906-265-E

$154.44 MSRP: $216.30You Save: $61.86 (29%)Volkswagen Oxygen Sensor Part Number: 022-906-262-CC

$154.70 MSRP: $216.67You Save: $61.97 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Right

Volkswagen Oxygen Sensor Part Number: 7B0-906-262

$155.47 MSRP: $217.75You Save: $62.28 (29%)Ships in 1-2 Business DaysProduct Specifications- Position: Front

Volkswagen Oxygen Sensor Part Number: 078-906-265-F

$157.08 MSRP: $220.00You Save: $62.92 (29%)Product Specifications- Position: Left

| Page 1 of 5 |Next >

1-20 of 92 Results

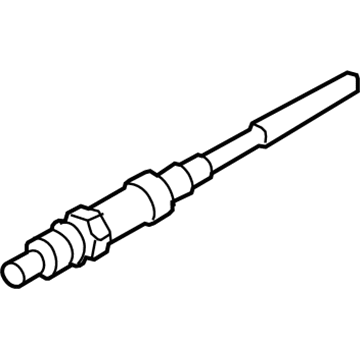

Volkswagen Oxygen Sensor

The role of the Volkswagen oxygen sensor in regulating fuel emissions is very important for better engine performance and fuel economy. It monitors exhaust gas and deposits developed by the engine, thus providing data about the air-fuel ratio. Whenever this ratio goes below or above normal values, the sensor relays information to the vehicle's engine control system for precise adjustment of the fuel mixture. Fluctuating idle speed and a sudden decrease in gas mileage are some telltale symptoms of a bad oxygen sensor. Heated sensors should be changed after 100,000 miles, while unheated sensors should be changed after 50,000 miles.

OEM (Original Equipment Manufacturer) Volkswagen Oxygen Sensors are perfect for motorists because they are the best quality parts produced as per the manufacturer's specifications; hence, they perform well and are reliable too, thus helping to retain the car's initial functionality as well as safety features. At VWPartsGiant.com, our genuine Volkswagen Oxygen Sensor supply indicates how much we care about the health of your vehicle. Additionally, our stock is vast, so every product will be easily accessible to you for finding and swapping without fear of making mistakes. With our user-friendly online catalog, it takes no time to identify the right spare part. Therefore, convenience accompanies servicing or maintaining a motorcar. You can rely on our OEM Volkswagen Oxygen Sensor to sustain the performance of your automobile.

Volkswagen Oxygen Sensor Parts and Q&A

- Q: How to properly service and remove an oxygen sensor without causing damage on Volkswagen Jetta?A:Since the oxygen sensor is fitted in the exhaust pipe, which is contracting when cold, it might be hard to loosen when the engine is cold. To prevent breaking an oxygen sensor or damaging its threads, ensure that you turn on and run the engine a minute or two then turn the engine off without burning yourself in the process. Particular care should be taken when servicing an oxygen sensor because they can never be taken apart by a permanent pigtail and have an electrical connector which cannot be removed; they would be permanently damaged. Also, do not allow grease, dirt and any other contaminants to touch the electrical connector and the louvered end of the sensor and never use any cleaning solvents on the connector. Oxygen sensors are very sensitive and therefore they should not be dropped or mishandled and the silicone boot should be fitted properly to avoid melting. Removing an upstream oxygen sensor: Find the oxygen sensor at the upper end of the catalytic converter or at the end of the exhaust manifold of 2.5L engines, and locate the wiring harness and strip the electrical connector of the sensor harness disengaging it. Unscrew sensor with an oxygen sensor socket to use on tight areas, and in case of re-insertion of the old sensor, apply anti-seize to the threads, which new sensors are already coated. In the case of downstream sensors, place the sensor in the centre and following the catalyst, disconnect the electrical connector, unscrew the sensor and place anti-seize compound in the case of replacing the old sensor. Installation is the opposite of removal and it is imperative to ensure that the oxygen sensor is firmly screwed to the required torque.

- Q: What are the differences in oxygen sensor configurations, and how do they function in relation to the ECM and air/fuel ratio on Volkswagen Passat?A:The four-cylinder models are fitted with two oxygen sensors, each pre-converter and post-converter, V6 models fitted with four each. The sensor elements interact with the oxygen in the exhaust to produce varying voltage output to a lean mixture of 0.1 volt to a rich mixture of 0.9 volt. The pre-converter sensor, which occurs in the front of the catalytic converter, provides feedback to the ECM about the oxygen concentration in the exhaust and thus it allows it to regulate the pulse width of the fuel injector and keep the air/fuel ratio at an optimal level at 14.7:1, resulting in optimal emissions, fuel economy and performance. The post-converter sensor, which follows the catalytic converter, has no effect on the air/fuel ratio, but assists the ECM in detecting efficiency of the catalytic converter by generating a slower changing voltage signal. The oxygen sensor does not produce a voltage until it reaches around 600-degrees F when the ECM will switch to an open-loop fuel control mode and depend upon other sensor inputs instead. The correct functioning of sensors needs proper electrical connections, free air circulation, right operating temperature, and usage of unleaded fuel. The ECM is able to detect different oxygen sensor faults and program diagnostic trouble codes and revert to open-loop control when defects arise. It is recommended to warm the engine a little to ease the removal of sensors and to take caution not to get burnt. In changing a sensor, the permanently attached pigtail and electrical connector are to be left in place and contaminants should be avoided in the connector and sensor end. The solvents are not to be cleaned and the sensor must be handled delicately. To replace the sensor which is of the pre-converter type, an opening is first achieved by removing the required parts, and to replace the sensor that is of the post-converting type, the vehicle should be placed safely on jackstands. Electrical connector is to be disconnected, and the sensor could be disassembled with the help of appropriate wrench or special socket. To ensure that the sensor threads could later be removed easily, one should apply an anti-seize compound to the thread, and then the sensor should be installed and firmly tightened after which the electrical connector has to be reconnected and the removal procedure should be followed in reverse.

Related Volkswagen Parts

Browse by Model

Arteon Oxygen Sensor Atlas Cross Sport Oxygen Sensor Atlas Oxygen Sensor Beetle Oxygen Sensor CC Oxygen Sensor Cabrio Oxygen Sensor Cabriolet Oxygen Sensor Corrado Oxygen Sensor Eos Oxygen Sensor EuroVan Oxygen Sensor Fox Oxygen Sensor GTI Oxygen Sensor Golf Alltrack Oxygen Sensor Golf Oxygen Sensor Golf R Oxygen Sensor Golf SportWagen Oxygen Sensor Jetta Oxygen Sensor Passat Oxygen Sensor Phaeton Oxygen Sensor R32 Oxygen Sensor Rabbit Oxygen Sensor Routan Oxygen Sensor Taos Oxygen Sensor Tiguan Limited Oxygen Sensor Tiguan Oxygen Sensor Touareg Oxygen Sensor Vanagon Oxygen Sensor